0603 SMD

The 0603 SMD, vital for compact electronics, offers space efficiency, versatility, and cost-effectiveness, crucial for industries like consumer electronics and automotive systems.

Tremendous change has been seen in design and construction within the world of electronics with the advancement from traditional through-hole components to Surface Mount Devices, or SMDs. Of the many SMD sizes, the 0603 package is extremely popular for efficiency, compactness, and cost-effectiveness.As experts at PCBX in printed circuit board design and content marketing, we look into the role, advantages, and considerations of the 0603 SMD in modern electronics.

The Shift to SMDs and Standardization

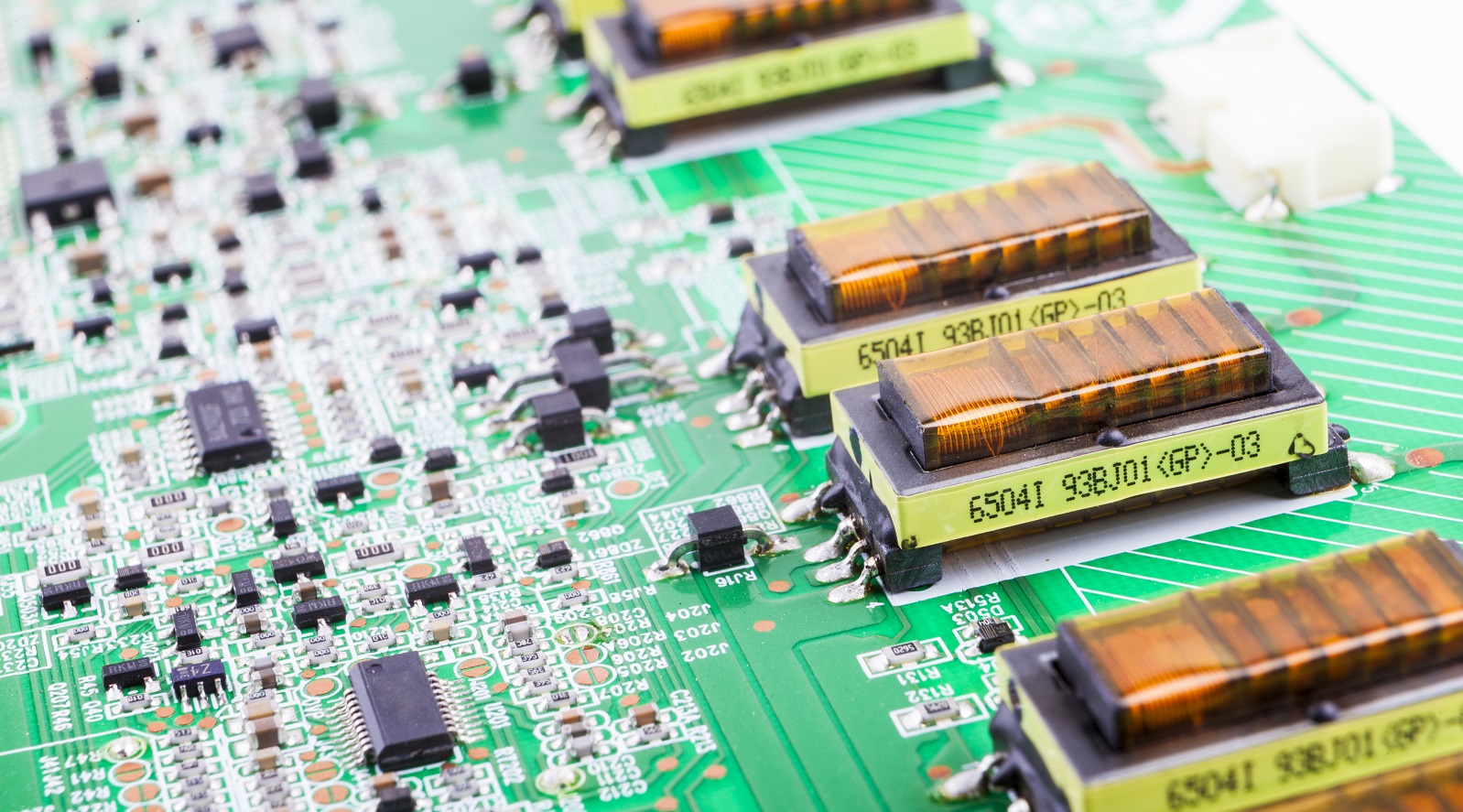

The move from through-hole to SMD was an important turning point in electronics design. Compared to through-hole components, SMDs have the advantages of being lighter, smaller, and more efficient, as they can be mounted directly on the surface of a PCB, thus saving space. Such a shift has been made stronger by standardization organizations such as IPC and JEDEC, which ensured that with each through-hole component, there is an SMD counterpart, inclusive of the 0603 package. This standardization simplifies the design process because it allows engineers to source similar components from a broad range of manufacturers, making the replacement of obsolescent parts very easy.

What is 0603 SMD?

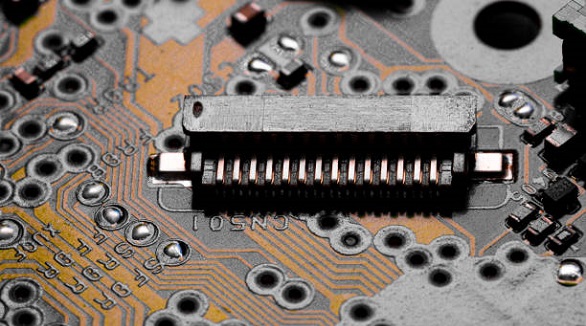

In the SMD categorization, the numerical code "0603" represents the component's dimensions in imperial units, with a length of 0.060 inches and a width of 0.030 inches, roughly 1.5 mm by 0.8 mm in metric. This kind of standardization is essential to ensure that components are easily integrable and replaceable in any electronic design, independent of the manufacturer.

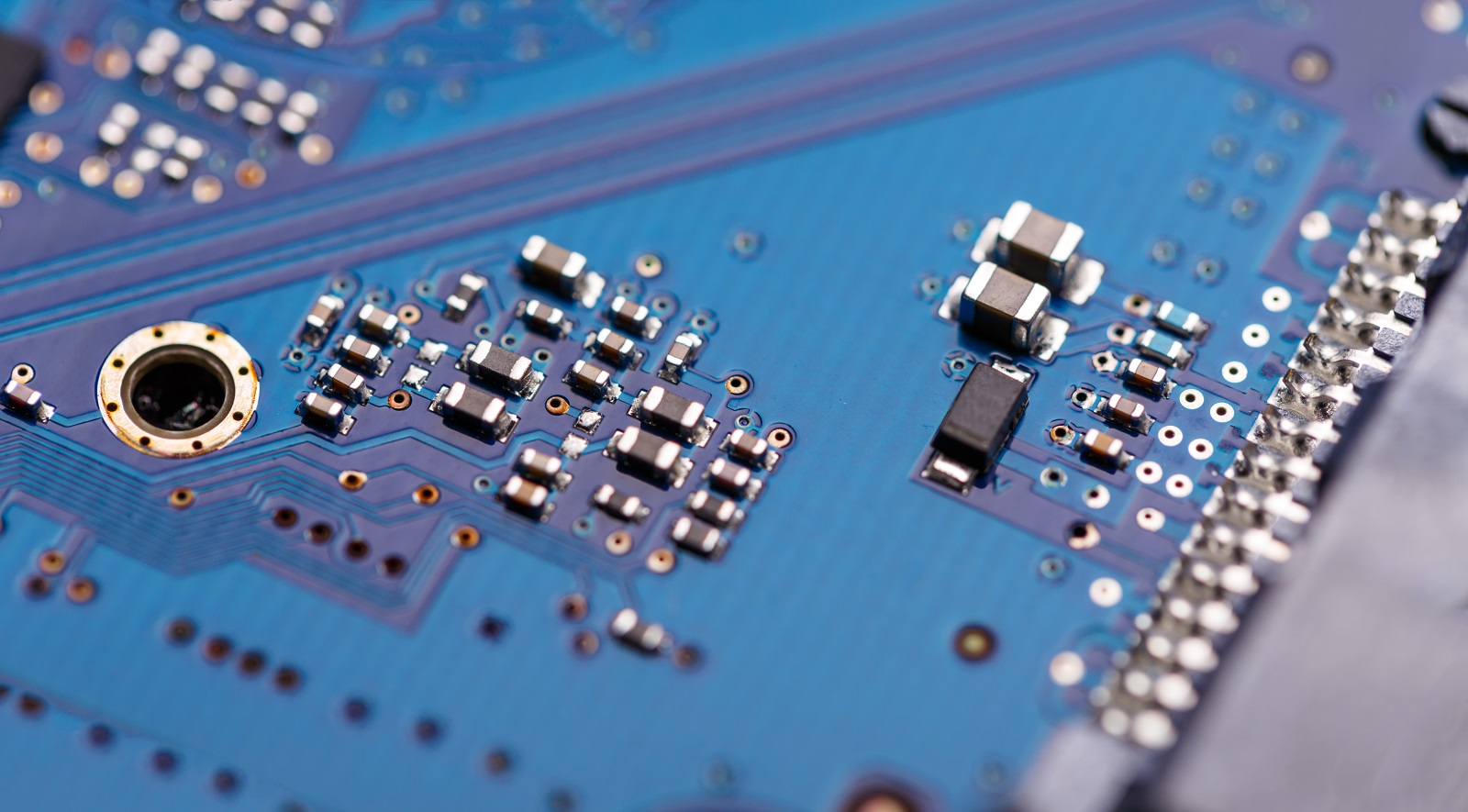

Due to their size being optimal for high-density electronic assemblies, 0603 SMDs are mainly utilized for passive components like resistors, capacitors, and inductors. Their small footprint makes integration of a number of components in limited space quite achievable, a thing very significant in modern days with the introduction of compact gadgets.

Benefits of 0603 SMD Components

Space Efficiency: 0603, or compact components are easier to use for high-density layouts on PCBs without increasing the physical size. It is really beneficial for those devices that are meant to work in conditions where space is strictly limited, such as smartphones, wearables, and IoT.

Cost-Effectiveness: Mass-producing 0603 leads to reduced cost of manufacture but still delivers. This makes its use very appropriate in cost-efficient productions where price factors are very stringent.

Versatility: Different forms such as resistors, capacitors, and inductors exist that can fulfill distinct circuit needs while coming under the header of 0603. This range helps designers for specific electrical characters required for most designs.

Improved Electrical Performance: By nature, SMT minimizes parasitic inductance and capacitance, which again enhances the electrical performance of high-frequency circuits.This is all important since recent designs of electronic devices require accuracies and also reliability.

Applications of 0603 SMD

The numerous uses of 0603 SMD components are noticeable in a couple of industry fields:

Consumer Electronics: Within a smartphone, tablet, and laptop, it's all about small form factor, and 0603 is more compact, thereby fitting more capabilities in smaller footprints without compromise to performance.

Automotive Systems: These are used within control units and sensors where reliability and compactness are required, together with resistance to extreme conditions found in automotive environments.

Medical Devices: These are much needed in miniature, portable, and wearable medical appliances where the size is as important as precision for innovating patient monitoring and diagnostic functions.

Industrial Controls: These are used in compact control systems and sensors where robust performance is balanced with space-saving requirements.

Design Considerations for 0603 SMD

The successful integration of 0603 SMD components into PCB designs requires careful consideration of several factors:

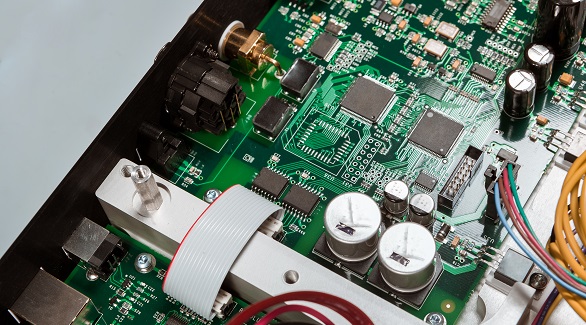

Precise Placement: Due to the small size, 0603 components need to be accurately positioned on PCBs. This accuracy is usually achieved by the use of automated pick-and-place machines. This reduces chances of problems such as tombstoning, where one end of the component lifts off the surface of the PCB during reflow soldering.

Soldering Precision: Too little solder yields poor connections, while too much will bridge. Therefore, the amount of solder applied has to be controlled. Strong and reliable joints can only be obtained by paying great attention to solder paste application and reflow profiles.

Thermal Management: With increasing complexity and component density on boards, managing heat dissipation effectively is essential. Poor thermal design can jeopardize component performance and longevity, necessitating the use of thermal vias, heat sinks, or conductive materials to spread heat.

Electrical Ratings and Limitations: Even though 0603 components are ideal for most applications, the small size inherently constrains current and power ratings. Designers using these components should follow appropriate derating guidelines to prevent failure or degradation in high-power applications, especially those with high frequency.

Land Pattern Compliance: Conformity to standards such as the IPC-7351 assures consistent land patterns for reliable solder joints. Most CAD software tools have a footprint generator that can be used to design compliant land patterns, ensuring design consistency and manufacturability.

Understanding Electrical Ratings

The electrical capabilities of 0603 SMD components are not covered under a single rating, as these are related with the particular type of component. There are also dependencies between performance and both materials and size. Smaller sizes result generally in more reductions to power-handling capability, and attention to this must be taken in order not to under-spec such applications.

Use of ECAD Tools

These SMDs are controlled with the crucial help of the software ECAD. It provides many helpful features in return: footprint management, replacing a component, including CAD models. The latter is useful for updating digital libraries while guaranteeing continuity of the designs and smooth transitions from design to manufacturing.

The 0603 SMD is an essential component in modern electronics, summarizing the culmination of efficiencies that fuel the miniaturization and functionality trends crucial to today's electronics landscape. This is why PCB manufacturers are always keen on having an optimal combination of small size, cost efficiency, and functionality. As electronic capabilities continue to evolve, demands for reliability and space efficiency with the SMD solution like the 0603 will most definitely be on the increase, extending frontiers beyond what is currently realized in electronic design. Innovation and understanding of the 0603 SMD among other components are at the fore of commitment to excellence with solutions in PCBs here at PCBX.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Hex inverter ICs are vital in digital electronics for signal inversion, logic functions, oscillators, and data transmission, enabling efficient circuit designs.

3-pin vs 5-pin: 3-pin offers simplicity in plugs and keyboard switches, ideal for residential and custom projects. 5-pin supports higher power and stability.

The 3.3K resistor is vital in electronics for current regulation, is widely available, and ideal in precision circuits, ensuring stability and cost-effectiveness.