A Comprehensive Guide to Through-Hole Technology (THT Assembly)

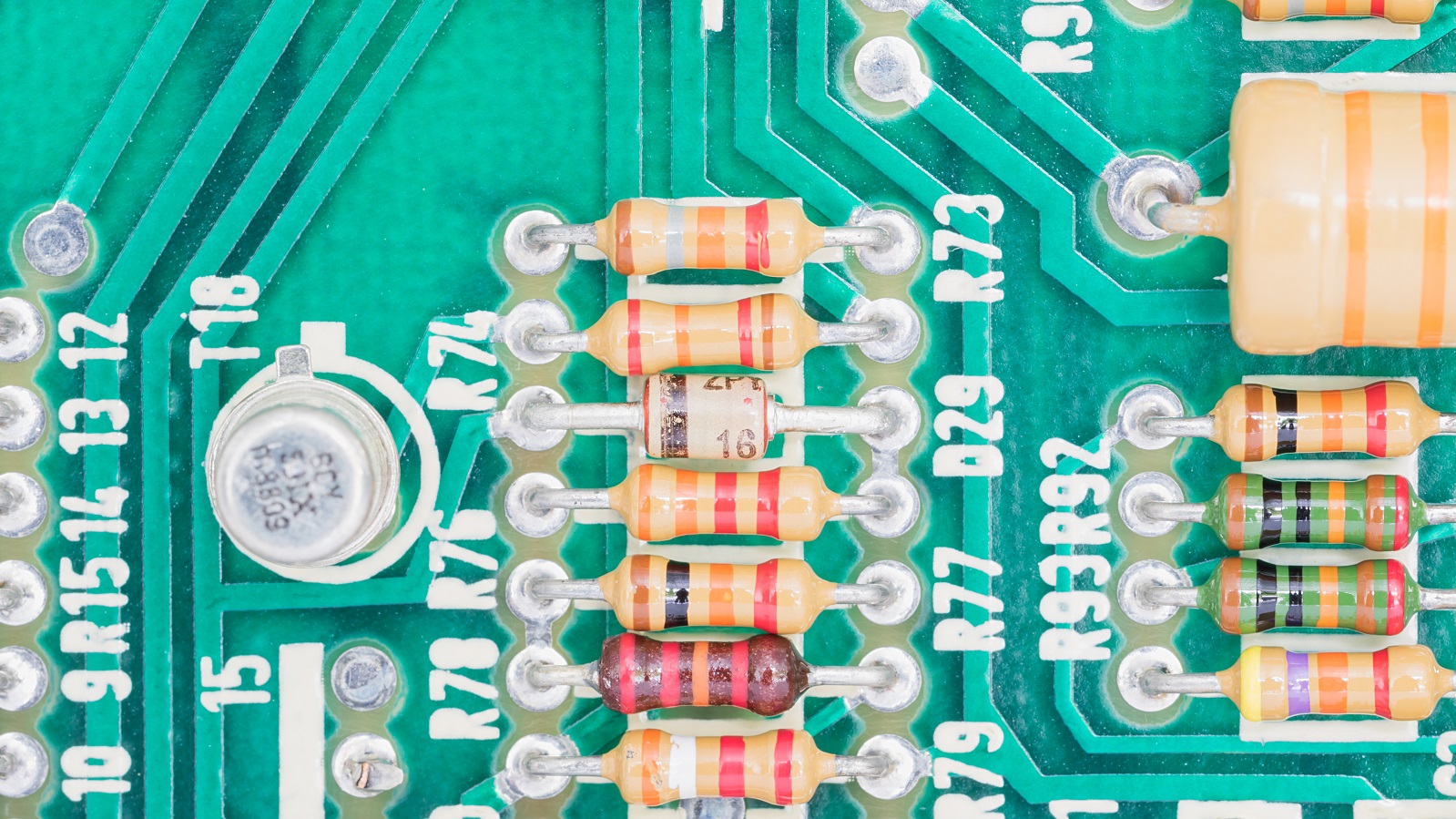

Through-Hole Technology (THT) mounts electronic components by inserting their leads through pre-drilled PCB holes and soldering them. While durable and ideal for harsh conditions, THT is less space-efficient than SMT.

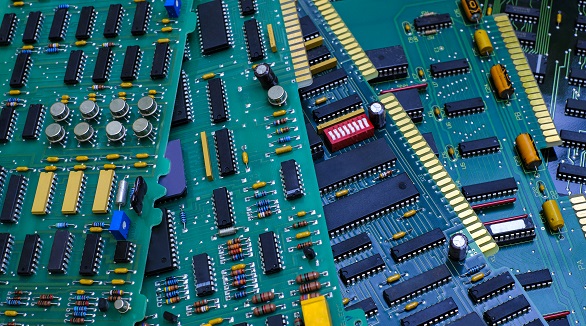

When designing and manufacturing a printed circuit board, component type and style are important considerations. Traditionally, components were inserted through holes punched into the PCB, which is still used today despite the prevalence of Surface Mount Technology. This page provides a detailed explanation of Through-Hole Technology, its distinctions from SMT, and its applications, as well as the numerous pros and disadvantages.

Understanding Through-Hole Technology

THT refers to the mounting of electronic components onto a PCB by their leads through pre-drilled holes and soldering into place on the opposite side of the board. In this way, such a process provides a strong and permanent connection, thus becoming perfect for high-reliability and durable applications.

In general, the following are processes involved in THT:

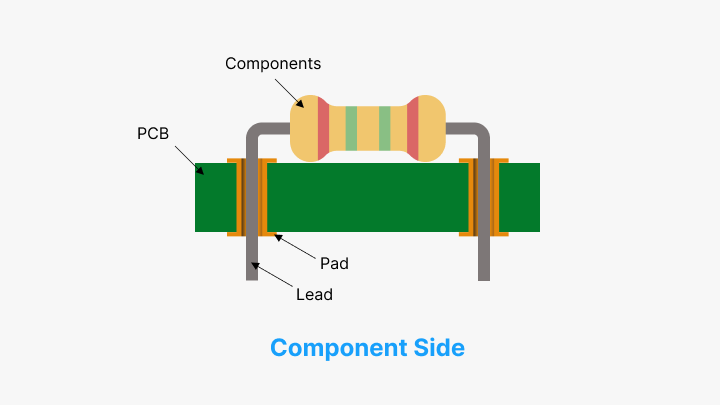

Drilling Holes: According to the component layout requirements, there will be some necessary drilling in the PCB.

Component Insertion: The component lead is inserted through the drilled holes.

Soldering: The lead is then soldered onto a pad on the other side to make a proper electrical bond.

The robustness of THT easily accommodates high-power components in extreme conditions such as very high temperatures and vibrations.

Operational Workflow of Through-Hole Technology

There are a few steps in the THT assembling process, which include but are not limited to the following:

Creating Holes: Holes are drilled in pre-decided locations on the PCB.

Component Placement: The components are inserted into predrilled holes and clamped or clipped into place. The component leads are soldered to the pads at the bottom of the board to create a good bond. In some instances, joints are inspected after soldering for defects such as cold solder joints. Cleaning of the Assembly: Cleaning is done on the PCB to remove flux residues and other impurities.

Final Testing Procedures: Intensive testing to ensure the functioning of all components and the stability of all connections.

Advantages of Through-Hole Technology

Through-Hole Technology endows electronic manufacturing with a number of advantages, as highlighted below:

Durability: Mechanically solid and resistant connection suitable for harsh environmental conditions.

Power Handling Capability: Can easily be used in high-power applications in power electronics.

Survivability in Harsh Conditions: Resistive to high level thermal and mechanical aggressions.

Cost-Effectiveness: Easy to assemble; hence, cost-effective on the part of the manufacturer.

Ease of Maintenance: Due to the simplicity of replacement, faulty components are easily replaced, and repairs become easy.

Extended Reliability: Offers a safer connection that extends the life of products by reducing their failures.

Extended Lead Times: Have longer leads; hence, this is suitable for applications where long-term reliability is a factor.

Disadvantages of Through-Hole Technology

Though advantageous, THT has certain drawbacks compared to newer methods like SMT:

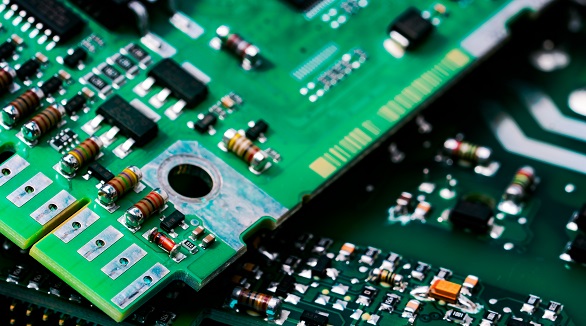

Space Utilization: Greater board space is used up by THT components; thus, it is less suitable for compact designs.

Weight Increase: Weight of the board definitely increased due to drilled holes.

Higher Costs: More procedures involved, like drilling, are often overall more expensive. Prolonged Assembly Time: Generally, it takes more time compared with automated assembly processes such as SMT.

Complications in Assembly: More use of manual labor increases error rates.

Lead Forming: The leads must be pre-bent to get them through the holes, which takes longer to assemble and can even cause lead damage.

Through-Hole Technology Applications

Owing to strength and reliability, THT finds wide applications in many industries that are:

Power Electronics: THT is suitable for applications involving high power, such as power supplies and motor control systems.

Military and Aerospace: Ideal for highly reliable environments in the sectors of defense and aerospace.

Industrial Automation: Very common in PLCs and servo drives, among other industrial control systems.

Medical Equipment: Present in life-critical equipment such as patient monitors and ventilators.

Consumer Electronics: Present in equipment such as televisions, DVD players, and gaming consoles.

Automotive Systems: They are indispensable in engine control, body control systems, and in infotainment applications.

Telecom Infrastructure: They are used in central office equipment, among other communication hardware.

Comparison between THT and SMT

Application of either of them is based on several factors:

Component size: The THT is better for bigger components that are difficult to surface mount.

Lead Pitch: SMT components have finer lead pitches and therefore are optimized for high-density designs.

Assembly Speed: Since it accommodates automated equipment, SMT can assemble parts much quicker compared to manual labor.

Automation Capability: SMT is mainly automated, which helps in improving efficiency by reducing error rates.

Component Availability: Components are fairly easier to obtain in THT; however SMT would be indispensable in modern, compact designs.

Reliability Considerations: The mechanical connections in THT are much more solid. Still, modern SMT designs have generally proven to be quite reliable.

Accuracy in Design: This would be easier to handle in designs where not much accuracy is required.

What is the future of through-hole technology?

While THT has been reliable and cost-effective for decades, competition from SMT has created a massive tide with even greater component density and downsizing. However, the procedure remains highly practicable in terms of durability and robust applications. Its lower prices might make it appealing to any small business or startup.

Conclusion

With its capacity to provide mechanical strength and durability that no other technology has been able to match up to this point, through-hole technology is still a highly important procedure in PCB manufacturing. For some applications that require endurance and stability, THT is still indispensable, even if SMT is the industry leader in high-density and compact designs. Depending on the size, performance, cost, and reliability requirements of your project, you can choose between THT and SMT. You can consult an expert at PCBX, a leading electronics manufacturing company, so you make the best choice to suit your needs.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Mixed Assembly PCBs combine Surface Mount Technology (SMT) and Through-Hole Technology (THT) for high-performance, compact, and reliable circuit boards. This integration leverages both technologies to enhance reliability, component selection, flexibility, and efficiency. Used in CPUs, IoT hardware, and more, they offer economic, efficient manufacturing for versatile applications in modern electronics.

Through-hole assembly is a key PCB manufacturing technique offering reliability and mechanical strength. This article details design elements, requirements, and standards, including thermal pads, IPC performance levels, component types, solder joint quality, hole sizes, and annular ring dimensions, ensuring robust and manufacturable PCBs for various applications.

Printed Circuit Board Assembly (PCBA) employs Through-Hole Technology (THT) and Surface Mount Technology (SMT). THT offers robust mechanical bonds, ideal for high-stress applications, whereas SMT supports efficient, high-density assemblies. Each method has unique advantages and limitations, impacting cost, manufacturing efficiency, and component compatibility. Understanding these differences is key for optimal PCB design.