Aluminum PCB vs FR-4 PCB

Select aluminum PCBs for excellent heat management or FR4 PCBs for cost-effective versatility in diverse electronic applications.

In modern electronics, the choice of printed circuit boards sets the ground for performance, reliability, and durability for any device. At PCBX, we understand how important the choice of the right type of material in the manufacture of a PCB will always seek to match or suit specific application needs.Aluminum PCBs and FR4 PCBs stand out among the most prevalent variants due to their distinct properties. This article examines some of the fundamental distinctions between them in order to help you make educated judgments when working on a range of electronics projects.

Material Composition

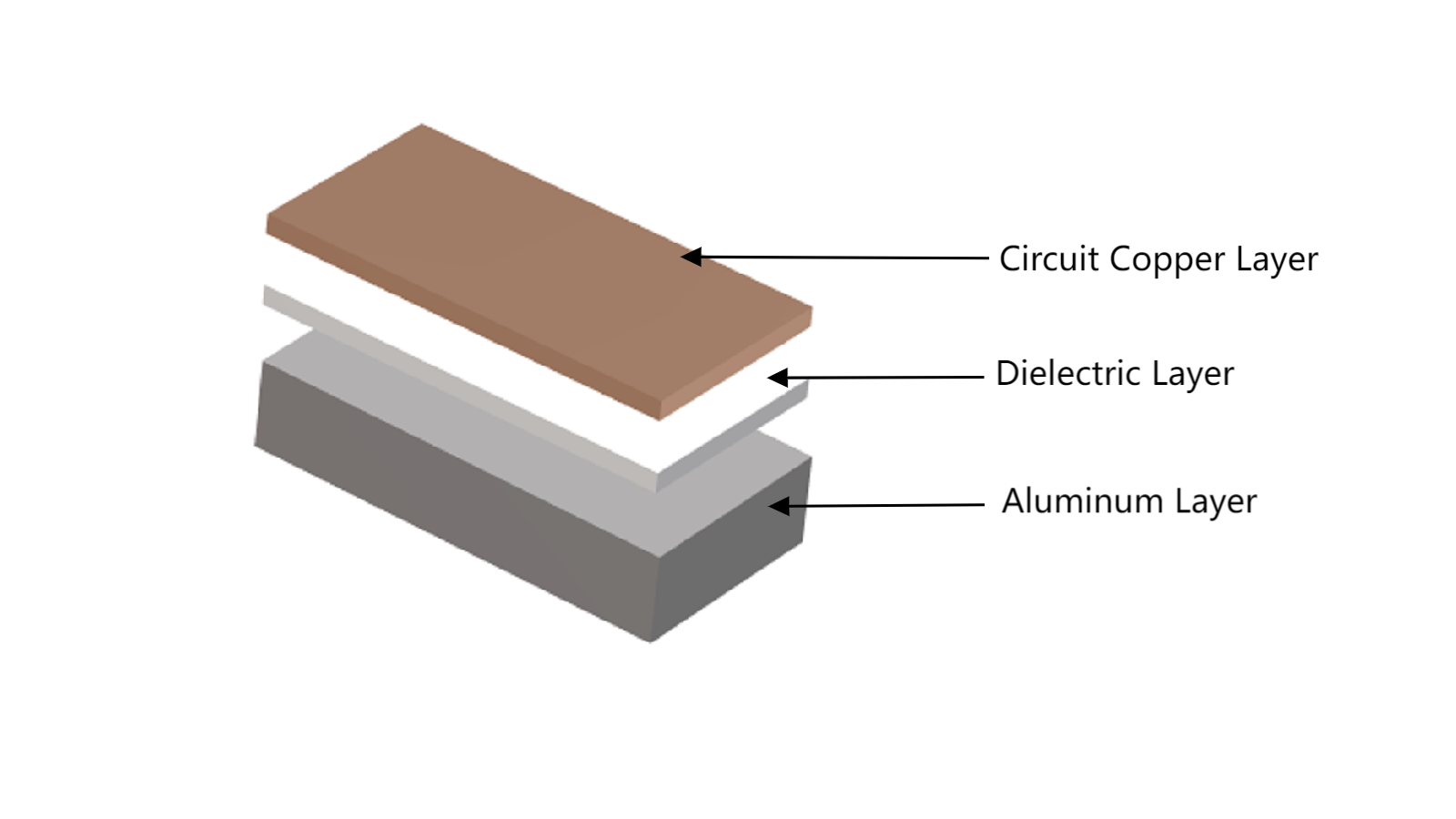

Aluminium PCBs:

Aluminum-based PCBs are well-known for their superior temperature management capabilities. They are typically composed of three layers: a metal base, a dielectric insulating layer, and a copper circuit layer. Because an aluminum core is employed, they provide excellent heat dissipation and hence find extensive application in areas where effective thermal load management is critical, such as LED lighting and power electronics.

The aluminum substrate ensures that heat emanating from electronic components is efficiently transferred away, thereby minimizing thermal stress to components, thus prolonging their life. This structural composition imparts superior mechanical strength and rigidity, which makes the material ideal for those scenarios that call for extended thermal cycling and mechanical stresses.

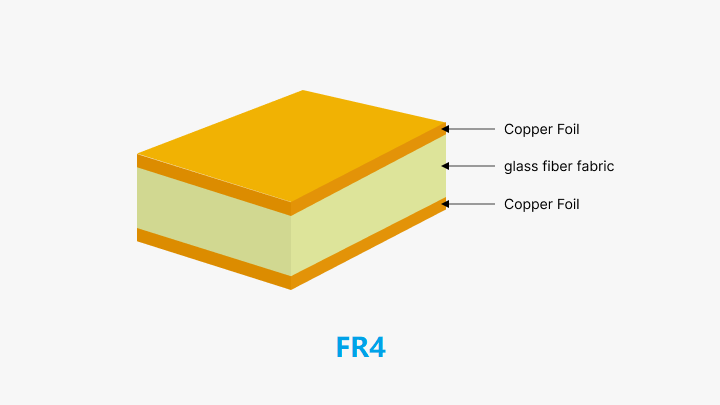

FR4 PCB:

Flame Retardant 4, commonly known as FR4, is a composite material of woven fiberglass cloth that contains an epoxy resin binder which has flame retardant properties. FR4 substrate has excellent electrical insulation, lightweight, and mechanical strength. Unlike aluminum PCBs, FR4-based PCBs are not designed to be very good thermal conductors; on the other hand, they are efficient and cost-effective for general electronic applications.

FR4 PCBs may be made in single layer, double layer, and multilayer configurations to meet a variety of design needs. The word "FR" refers to fire resistance compliance, as defined by the UL 94V-0 specification, which states that the material will resist ignition for a set amount of time in particular applications, providing an additional level of safety in electronic design.

Thermal Conductivity

Aluminum PCB:

The fundamental benefit of aluminum PCBs is their better heat conductivity. As previously stated, aluminum is an excellent heat conductor; hence, it is frequently employed in a variety of applications requiring its heat-conductive qualities. A common application is LED lighting systems that operate under generated heat, which needs to be effectively managed in order to preserve the operational performance and extend the life of the LEDs. The ability of aluminum for fast heat transfer enables such PCBs to support high-performance operations without overheating.

FR4 PCB:

FR4 PCBs, on the other hand, have innately low heat conductivity due to the glass fiber-reinforced epoxy glue used to produce the material. This constraint makes FR4 PCBs less suitable for use in extremely high-temperature applications. Additional cooling, such as heat sinks or fans, might be required in order to prevent thermal build-up-particularly in closely-packed or power-intensive designs.

Coefficient of Thermal Expansion

Aluminum PCB:

CTE is the 'rate at which the material expands and contracts with temperature change'. In general, aluminum PCBs possess a CTE much closer to that of copper, ensuring minimal thermal stress between the different layers of the PCB. Such symmetry is fairly helpful, mainly when ensuring reliability and life expectancy in solder joints and metallized holes that can quite regularly fail due to thermal fatigue.

FR4 PCB:

It tends to contain a higher CTE, which is not good to manage, especially in respect to the board's thickness direction. More precisely, the mismatched expansion among FR4 substrate and copper traces may give rise to mechanical stresses impinging upon the integrity of solder joints, hence triggering failures in extreme conditions of thermal cycling.

Laminating Layers

Aluminum PCB:

The laminating layers consist of an FR-4 core material, an aluminum layer, and two bonding films.

It is fabricated on a specific layering scheme that constitutes the structure of an aluminum PCB. It comprises a metal base, a dielectric layer, and a conductive copper layer. The layering is three-layered and most effective for applications in which good thermal performances are to be given or resistance against high temperature is necessary.

FR4 PCB:

FR4 PCBs are also more flexible in terms of layer configuration, from single to complex multi-layer configurations. This versatility enables engineers to develop designs ranging from simple circuits to sophisticated circuits to meet a wide range of electrical requirements without being constrained by the temperature restrictions seen in metal-core PCBs.

Mechanical Strength and Rigidity

Aluminum PCB:

Most notably, these PCBs feature an aluminum core, which makes them significantly stronger structurally and stiff; hence, they are used in heavy-duty applications where several components require robust support. This then makes them very valuable in aggressive environments due to the fact that they show resistance to mechanical and thermal stresses.

FR4 PCB:

While FR4 PCBs are rigid yet lightweight, they lack the rigidity of aluminum-core boards. They work in applications where there is just a standard electronic circuit without major extremes in mechanical tension. This makes it easier to manufacture and manipulate.

Thickness

FR4 PCB:

The thickness of FR4 boards can be so varied, especially for multiclay constructions, that a wide flexibility in design for specific spatial and functional needs in PCBs can be achieved.

Aluminum PCB:

The requirement for good heat dissipation usually dictates the thickness of the aluminum substrate. The thinner substrate, in conjunction with the dielectric layer, yields a thinner profile, suitable for applications that require thermal management to take precedence over layering.

Applications

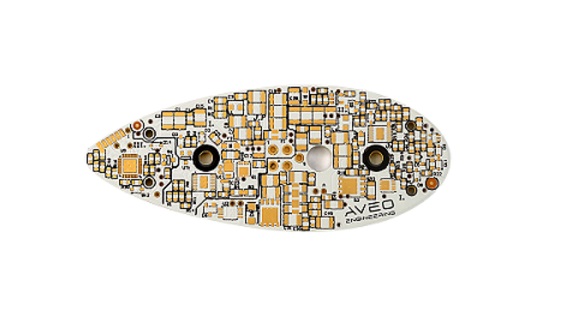

Aluminum PCB:

With high thermal and electrical conductivity, aluminum PCBs are the solution to be applied in every process. Other than LED lighting, they find wide applications in power modules, high-power RF applications, and automotive electronic systems where superior heat management can improve performance and reliability.

FR-4 PCB:

However, FR4 PCBs have a wide range of electronic applications. They are well suited to applications such as telecommunications equipment, consumer electronics, computer hardware, and so on, where complex heat management is not a major concern. Special high TG FR-4 variations improve performance at high temperatures, increasing the material's flexibility.

The decision between aluminum and FR4 PCBs necessitates careful evaluation of the application requirements, particularly heat demands and mechanical limits. At PCBX, we are very cautious to deeply understand these core differences so as to support our clients in navigating the various options available to them in their particular PCB need. Among others, Aluminum PCBs stand out with fantastic performance in high-temperature and high-power scenarios due to the high level of reliability and longevity through efficient thermal management. On the other hand, FR4-based PCBs provide flexibility and low cost for general applications; they assure reliable performance without claiming sophisticated thermal solutions.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

ENEPIG is a high-performance PCB finish with nickel, palladium, and gold layers, offering superior solderability, corrosion resistance, and wire bonding for critical industries like aerospace and telecom.

Gold plating in PCB manufacturing increases electrical properties, durability, and corrosion resistance, ideal for high-reliability applications. Types include ENIG (common, flat, solderable) and ENG (thicker, durable).

Aluminum PCBs are widely used electronic boards with comparatively better heat dissipation properties. The aluminum core cools down the components of the product, thereby improving its performance. These are eco-friendly, light, and strong PCBs and hence appropriate to be used in audio equipment, power supplies, and lighting products such as LED lighting.