Arduino Nano vs. Arduino Micro

Arduino Nano and Micro differ mainly in USB capability and I/O options, with Nano suited for simple projects and Micro for USB-intensive, compact applications.

Arduino is an open-source electronics platform that just about revolutionized the entire approach of hobbyists and professionals in their electronic projects. With a number of versatile boards that it has developed, its Arduino Nano and Arduino Micro remain popular due to compact size and respective capabilities. The following guide reviews two such popular Arduino boards, Arduino Nano and Arduino Micro, for major differences in specification, functionality, and use.

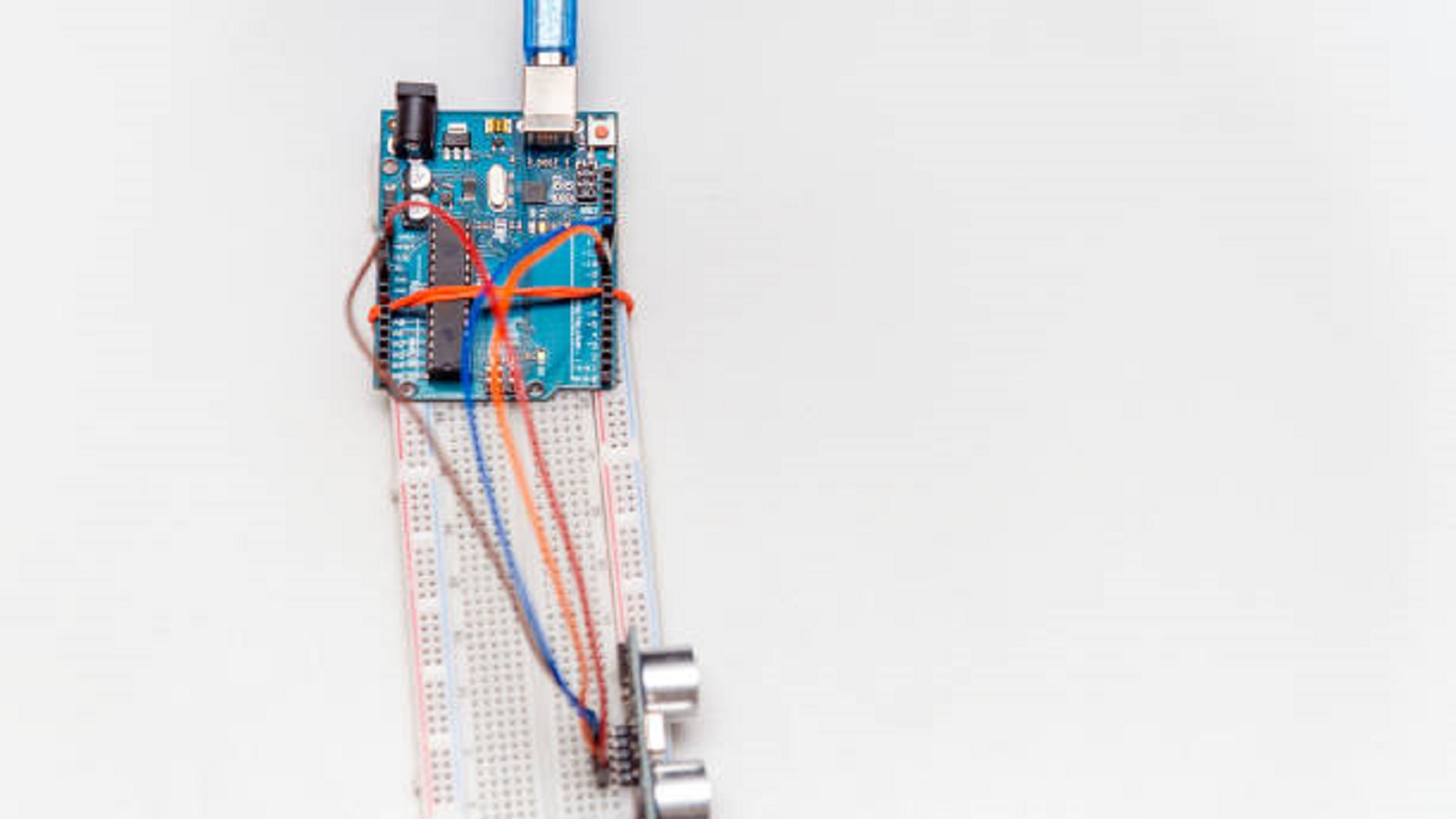

Arduino Nano

The Arduino Nano is considered one of the smallest and inexpensive boards in the Arduino series of boards. It includes the main elements that can be used in a large number of projects:

Microcontroller: ATmega328P

Operating Voltage: 5V

Digital I/O Pins: 22 (including 6 PWM outputs)

Analog Input Pins: 8

Flash Memory: 32 KB

Clock Speed: 16 MHz

Size: 18 x 45 mm

Thanks to its small form factor and breadboard compatibility, the Nano is a perfect fit for applications that cannot allow an additional block of space. The pin layout, from a design perspective, is similar in form to that of the Arduino Uno and thus, programs written for one can be ported to the other without necessarily altering them.

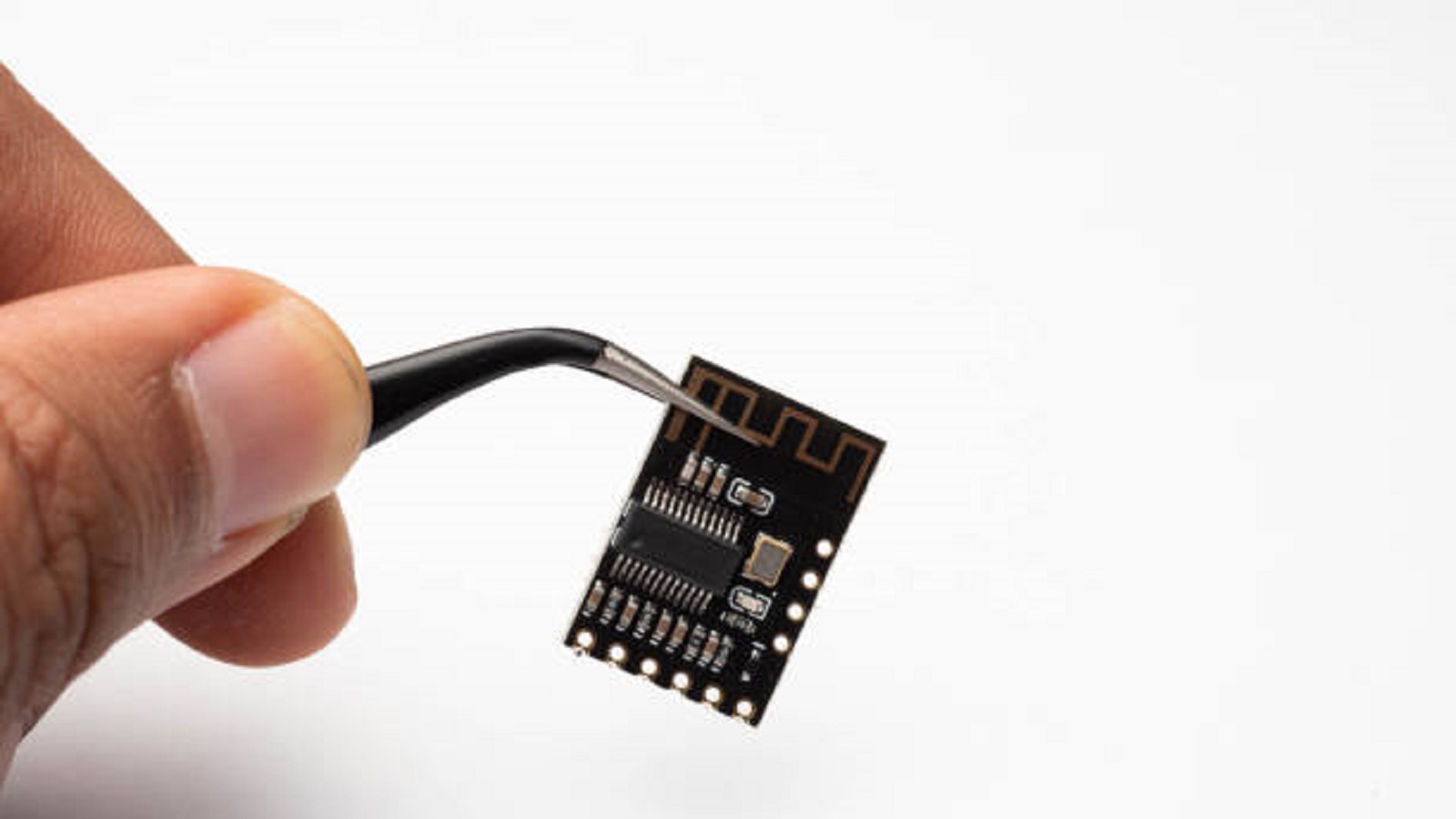

Arduino Micro

The Arduino Micro is a more capable device than the Nano. For the most part, this is due to the upgrade of the microcontroller used in this board. Some of its features include:

Microcontroller: ATmega32U4

Operating Voltage: 5V

Digital I/O Pins: 20 (with 7 PWM outputs)

Analog Input Pins: 12

Flash Memory: 32 KB

Clock Speed: 16 MHz

Size: 18 x 33 mm

As the name would suggest, the Micro's USB communication natively makes it suitable for projects that require USB connectivity. Its small size and an integrated USB plug make it more favorable in applications that demand direct USB interface.

Hardware Detailed Comparison

Microcontroller Capabilities

Nano: This is the default go-to microcontroller for basic projects requiring a lot of space and reliable performance, though for less complex tasks.

Micro: The microcontroller, ATmega32U4, has native USB capability; hence, the board can impersonate USB peripherals like keyboards and mice. This makes it an advantage over the Nano's microcontroller.

Input/Output and Connectivity

Nano: It contains 22 digital pins, 6 PWM channels, and 8 analog inputs.

Micro: Offers 20 digital pins, 7 PWM channels, and an increase to 12 analog inputs so you can have even more extensive projects with sensors and interfaces.

The additional analog pins on the Micro make it even more versatile for complex projects that would require a wide range of sensor inputs.

Memory and Speed

Both boards have the same memory configuration, with 32 KB of flash memory and a standard clock speed of 16 MHz. However, the Micro is packed with 2.5 KB of SRAM, more than the 2 KB on the Nano, and thus offers superior performance when operating on large amounts of data.

Power and USB Features

Nano: This board uses a Mini-B USB and requires external converters to communicate over USB.

Micro: Uses a direct Micro-B USB connector, has great, out-of-the-box USB because of the expanded capabilities of the ATmega32U4.

Because of its USB capability, the Micro can natively support much faster data transfer than the Nano, which relies on an external USB-to-serial setup.

Dimension and Mounting Considerations

Nano: 18 x 45mm in size, has no mounting holes.

Micro: Slightly smaller at 18 x 33 mm in size, with integrated mounting holes; thus, more robust with a built-in USB connector.

The reduced size of the Micro makes it appropriate for projects with tightly constrained space.

Software and Performance Insights

Processor and Core Distinctions

Nano: Uses ATmega328P core. Relies on standard support for Arduino shield and libraries.

Micro: Based on the Leonardo core, which also includes the USB communication libraries, that enlarge the range of possible applications.

Data Transfer and Processing

Nano: Only supports UART speed up to 2 Mbps.

Micro: This board has full-speed USB 2.0 capability, transferring up to 480 Mbps - considerably faster with operations requiring USB.

This difference in speeds therefore makes the Micro board a perfect choice over the Nano for projects that need a high transfer speed interface.

Peripheral Integration

Nano: Traditional design for simple I/O applications.

Micro: Inherited advanced peripherals onboard reset button, LED directly connected to the microcontroller; extended functionalities of UART, SPI, and I2C.

These additional features would support the value of Micro in being more usable for most embedded applications that require complex scenarios.

Choosing the Right Board for Your Project

The boards are relatively in the same price range of $20-$25, with some third-party versions also available as low as $10, and hence cost is a very minimal differentiation factor.

Arduino Nano: Suited for initial learning, simple robotics, and wireless sensor networks where onboard USB communication is not needed.

Arduino Micro: Good for projects in which direct USB connectivity, HID, IoT nodes with wired networking capability, spacing is limited, and applications for advanced sensing.

Applications that do not involve the use of USB can use either board and may be selected based on spacing and the extent of I/O complexity.

Knowing what makes the Arduino Nano different from the Arduino Micro will enable you to decide which one to use. Though the boards excel in different areas, your application decision will be based on either USB embedding, space constraint, or analog input. With this guide, now you are adequately equipped to make an informed decision that would enable you to unlock the full potential of your Arduino projects-by teaching, developing, or innovating.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

PCBX's new platform streamlines PCB design, offering real-time simulations, prototyping, and collaboration tools for students, hobbyists, and professionals.

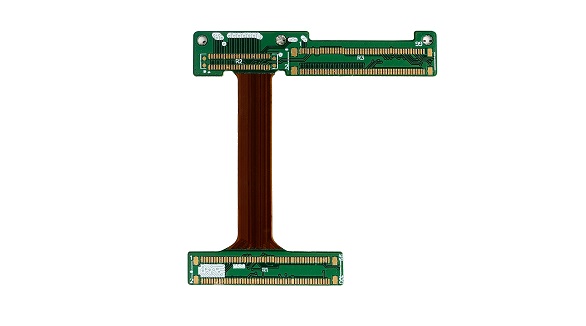

Flex PCBs fit into devices, saving space, while Rigid-Flex PCBs combine flexible and rigid parts, ideal for varied applications. PCBX offers custom designs, rapid prototyping, and high-quality manufacturing.

Most electronic circuits are mounted on PCBs, or Printed Circuit Boards, which provide mechanical support and electrical interconnection of electronic components. There are, however, special applications that involve the use of single and double-sided PCBs, multi-layer PCBs, or even rigid and flexible PCBs with aluminum backing, targeting medical, industrial, auto, and aerospace industries. They may use materials such as fiberglass, epoxy, aluminum, and others.