Avoiding Common BGA Rework Mistakes

BGA rework is complex, requiring skilled training, quality tools, precise thermal control, and thorough inspections to prevent costly errors and improve PCB assembly efficiency.

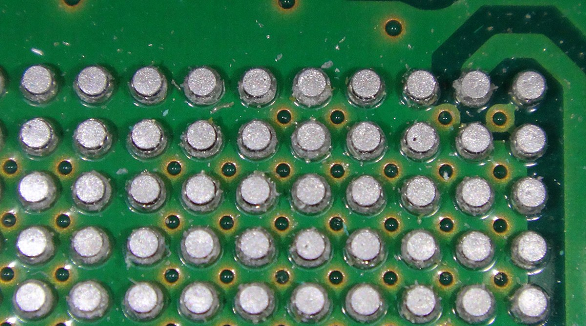

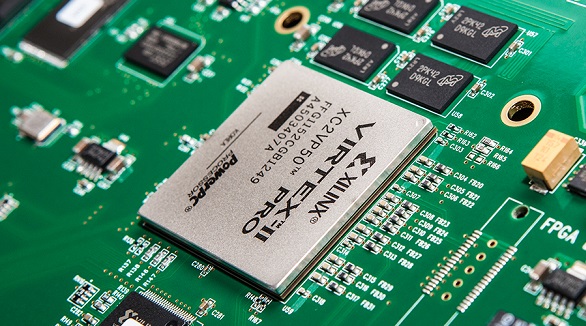

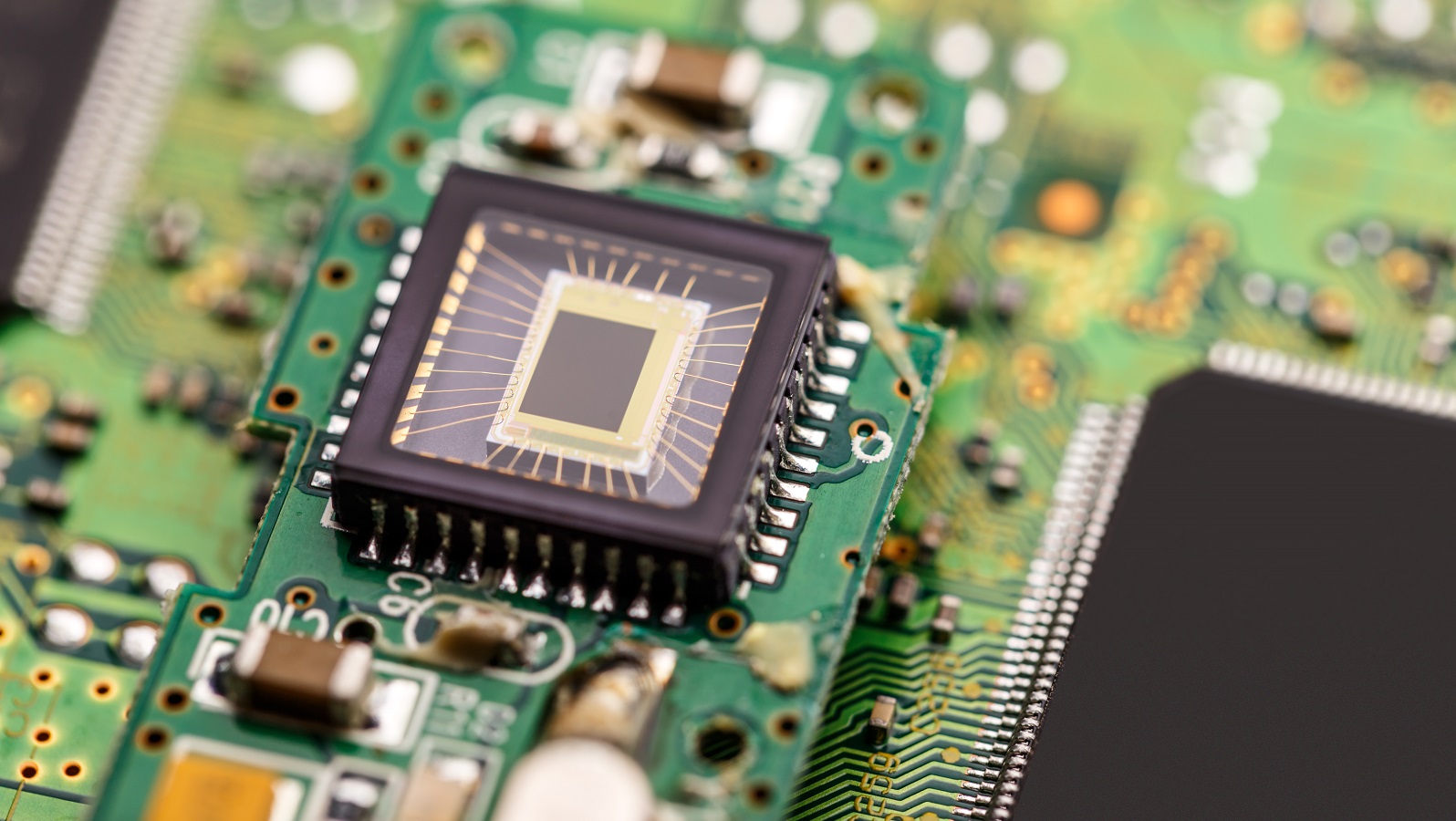

Among all the operations related to the assembly and repair of printed circuit boards, one of the most challenging tasks is BGA rework. These BGAs are permanently designed to integrate circuits, and their rework is quite intricate. The best-laid processes are easily susceptible to a number of common mistakes that further result in costly and time-consuming reworks. This guide tries to point out some of these common mistakes and offers some insight into how to avoid such mistakes to make such tasks easier and more efficiently carried out.

Common BGA Rework Mistakes and Prevention

1. Inadequate Operator Training

Problem: Any BGA rework success is very dependent upon expertise and experience from technicians. Improper training may lead to incorrect handling, wrong soldering methods, and incorrect procedural checks-all of which will void any hopes of effective rework.

Prevention:

Thorough Training Courses: Technicians will be put through rigorous training, which will have regular upgradations concerning the latest techniques and technologies. The training topics range from basic material properties to sophisticated equipment usage.

Hands-on Training: This will involve detailed practice that will help in developing the needed skills for BGA rework, which includes soldering, reworking, and assembling.

Standards Compliances: It should also cover the training of industry standards like IPC-A-610F and IPC 7095, which will further advance the technicians in their understanding of Quality Assurance and Process Control.

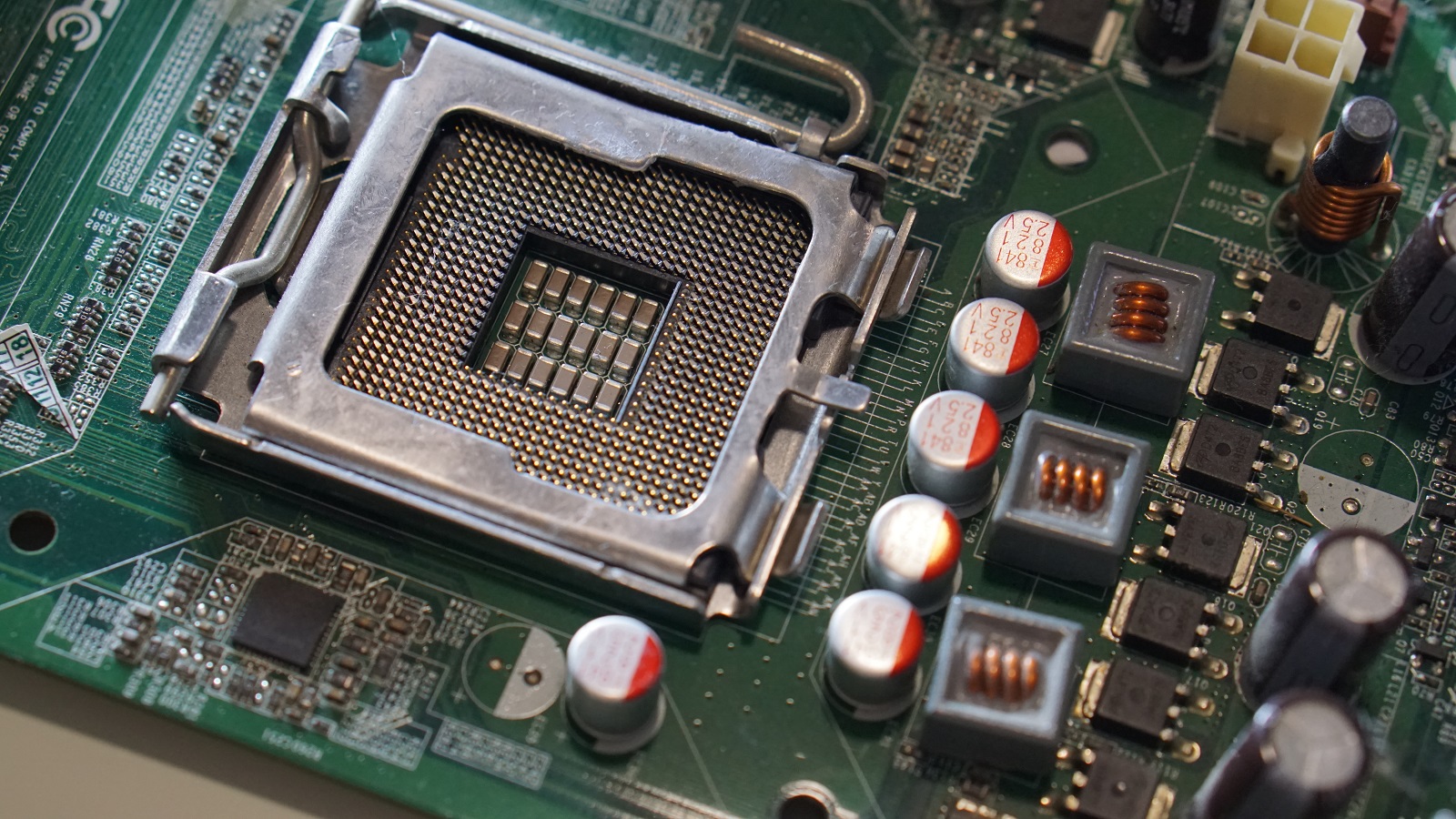

2. Poor Equipment Selection

Problem: Selection of equipment is most important in BGA rework. Application of inadequate tools creates a much larger effect of inefficiency and component damage than one might predict. The rework station should be equipped with high-quality, universal types of tools with possibilities for precise adjustment and constant reproducibility.

Prevention:

Investment in High-Quality Tools: Provide the rework station with high-performance features like closed-loop thermal sensing, robust heat delivery systems, and precision product handling. These should be controlled and repeatable processes.

Takes Shortcut: Taking shortcuts by using inferior quality tools will only allow for more rework and damage to manifest. The best way to avoid most common issues is investing in good tools right from the start.

3. Poor Profile Development

Problem: The specific thermal profile development is the most critical thing in BGA rework. A poorly developed profile can potentially damage both the BGA and the neighboring parts, increasing the number of additional rework cycles and the risk factors involved. This could finally result in loss due to part or overall system failure.

Prevention:

Thermal Profiling Carefully: Spend time creating good thermal profiles on the component, using thermocouple placement and data interpretation, helping to make the process non-variable and reliable.

Assembly Profiles Replication: The rework profile shall follow the original assembly reflow profile as much as possible to maximize the consistency of results with minimal chance of damage.

4. Poor Preparation

Problem: Poor preparation will lead to a host of problems that range from moisture entrapment causing 'popcorning' to damage of heat-sensitive components during the process.

Prevention:

Moisture Control: Pre-baking of the BGA and PCB assembly for the removal of moisture should be done prior to the commencement of the rework process.

Component Protection: Removal or proper protection of adjacent heat-sensitive components should be ensured to avoid accidental reflow or damage.

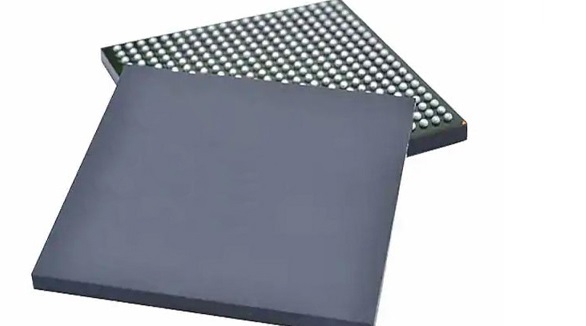

Correct Assessment: Technicians are supposed to check solder ball size, co-planarity, as well as the status of the pads and solder masks in order to ensure all components are correctly placed before rework actually commences.

5. Collateral Heat Damage

Problem: Collateral heat damage refers to an instance when the heat applied for the rework process has accidentally reached or altered other neighboring components. This would result in several problems, which include oxidation in the solder, pad damage, among others.

Prevention:

Reduce Heat Smearing: Create thermal profiles that allow focusing heat application to have a minimal quantity of heat transfer to other surrounding components.

Constant Awareness: Technicians should always be aware of the area around the target BGA component and other neighboring parts for any effects of heat and, based on this observation, should adjust the thermal profile to avoid unintended damage.

6. Lack of Proper Inspection after Placement

Problem: Poor alignment, excessive voiding, and incorrect placement are some of the problems that may not be observed when there is a lack of enough post-placement inspection, which might lead to faulty connections needing further reworks.

Prevention:

Advanced Inspection Techniques: Employ X-ray inspection for detailed imagery and reliable diagnostics of solder joint patterns. Advanced optical and electrical inspection techniques can help in finding hidden defects.

Training on Inspection Tools: Ensure that technicians are proficient in using these inspection tools and can accurately interpret the results. Proper training in reading X-ray images, as well as interpreting other diagnostic data, is critical to expedite quality control.

Essential Equipment for Effective BGA Rework

A well-equipped rework station is an essential requirement for executing successful BGA rework. The key tools and equipment required are:

Input is invited via additional electronics and software for increases in precision and control. Suction tools with pressure adjustment remove components safely without damage. High-resolution cameras ensure that placement and alignment are accurately done. Adjustable X-Y tables offer flexibility and precision in component handling. The temperature-controlled systems maintain consistent and controlled thermal profiles. Split-beam prism alignment systems align components with a great deal of accuracy.

Continuous Improvement Through Professional Guidance

Industry professionals such as PCBX provide in-depth training and consultancy services to help organizations improve the efficiency of their BGA rework processes. Training and consulting services assure increased preparation by technicians, processing efficiency, and equipment modernization to reduce error rates and boost productivity in general.

Training and Consulting

Specific Training Programs: From Lead/Lead-free Solder Techniques to Advanced BGA Rework and Reballing, classes targeting very specific needs.

Consultancy Services: These cater to the needs of business agencies in improving operational efficiency and maintaining equipment at an optimal level. In this regard, consultancy would be extended to resolve all issues pertaining to process optimization right up to equipment maintenance.

Conclusion

The best avenue to ensuring a BGA rework process avoids the most common mistakes is assurance of reliability and repeatability. By addressing comprehensive training, quality equipment, accurate preparation, precise thermal profiling, vigilant monitoring, and thorough post-placement inspection, businesses have the ability to reduce the quantity of highly costly reworks and boost overall efficiency. Indeed, this translates to increased yields, reduction of costs, and a better bottom line concerning your PCB operations.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.