BGA vs. LGA: Understand the Differences and Choose the Right Package

The article compares Ball Grid Array (BGA) and Land Grid Array (LGA) packaging technologies for mounting microprocessors on PCBs. It details their pros and cons, applications, and factors to consider for optimal design choices.

Mounting microprocessors and integrated circuits onto a printed circuit board requires making the right choice among the different packaging technologies. The two most popular techniques of packaging applied in the electronics industry are known as Ball Grid Array and Land Grid Array. Each has its positive and negative points, besides specific fields of application. The article compares the two technologies in detail with a view to enabling designers and engineers to make informed choices in the implementation of packages within their projects.

What Is BGA and LGA?

Land Grid Array (LGA)

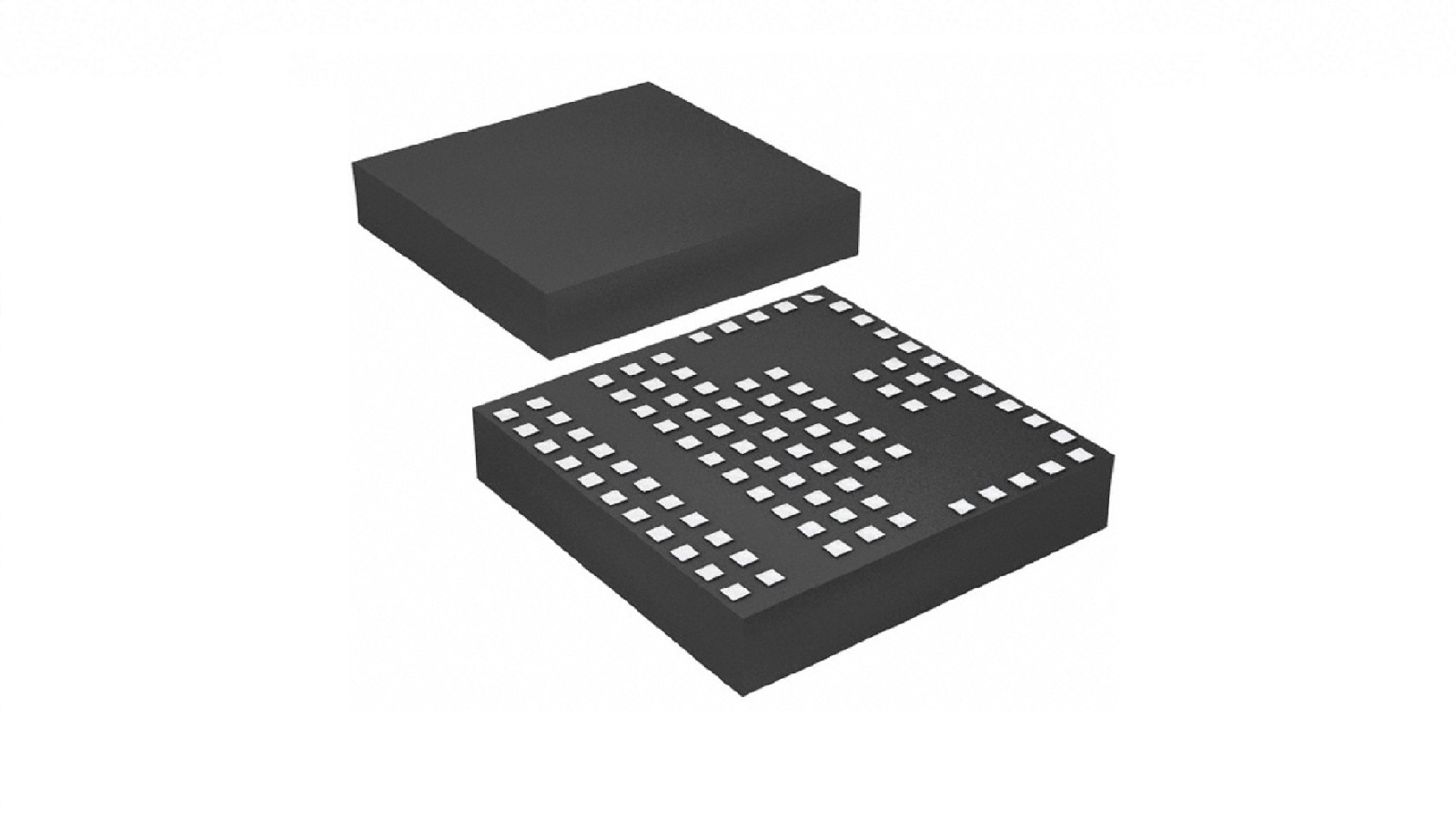

LGA is a form of packaging technology mainly utilized to mount microprocessors and integrated circuits on the PCBs. A distinguishing feature of the LGA is its uses in metal contact pads on the bottom surface of the package in a grid-like pattern. These pads make contact with the corresponding pads on the PCB and facilitate both the electrical and the mechanical connections. Most of the LGA implementations, unlike the rest of the packaging methods, need a retention mechanism in order to exert regular contact pressure.

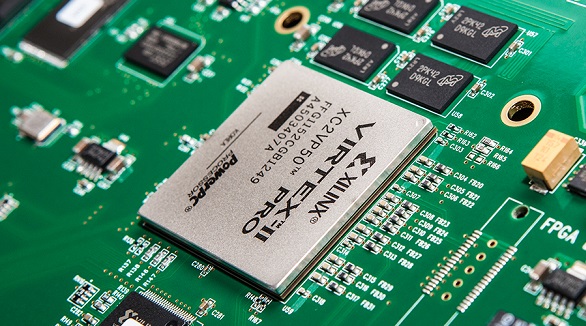

Ball Grid Array (BGA)

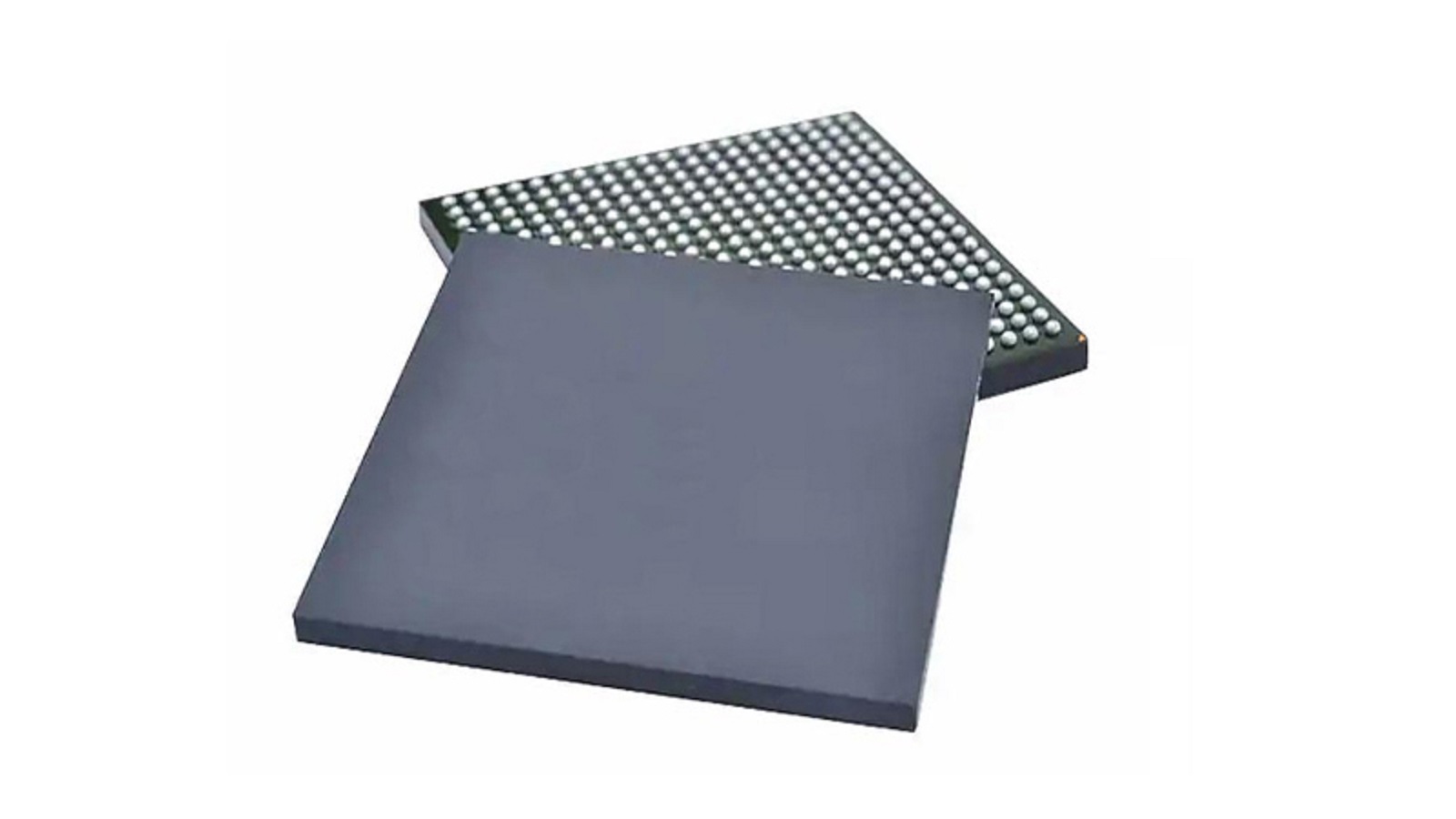

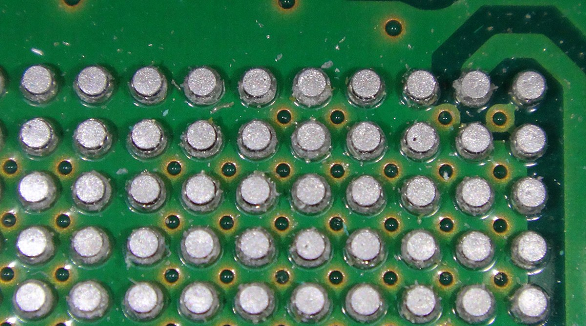

BGA, on the other hand, makes use of a plurality of small solder balls in a grid-like fashion under the device. These are used both as an electrical contact and as a mechanical support. During the reflow soldering process, these solder balls melt and provide a reliable connection between the component and the PCB. BGAs are characterized to have high I/O density, thus they are good for applications that demand a large number of connections within a limited space.

Key Differences Between LGA and BGA

Contact Mechanism

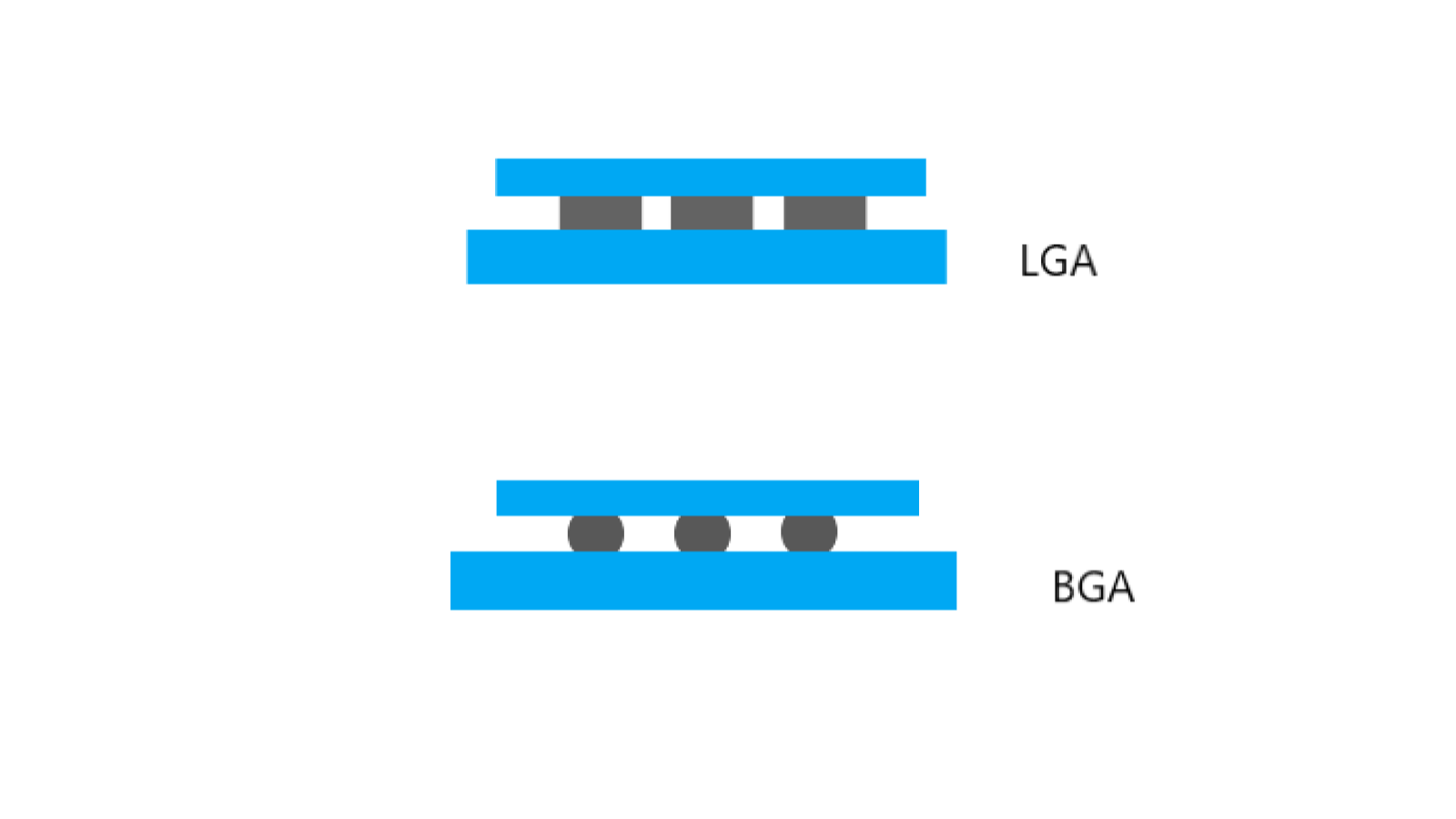

The basic difference in design is with respect to the method of establishing electrical contact between each package and the PCB pads. In this regard:

LGA Package: The electrical contacts are made through flat metal pads on the bottom of the package. The contact pressure is maintained through an interposer or a retention mechanism.

BGA Package: Solder balls melt during reflow soldering to establish both electrical interconnections and to provide mechanical support.

Pitch, or the distance between the center of each contact or ball in general, is smaller for BGA packages. More connections can fit on a small space, which makes BGAs suitable for high-density designs.

Thermal Properties

Normally, BGA packages give better thermal performance because of the uniform heat transfer provided by the solder balls. On the contrary, LGA packages can be poor in terms of thermal performance as their pins get in the way of dissipating heat.

Repairability

LGA: Easier to inspect and repair since the contacts are accessible.

BGA: A bit harder to repair since the solder balls are hidden and need special tools and techniques.

Cost

BGA packages tend to be more expensive to manufacture as they include the extra solder ball attachment process. Typically, LGA packages are less expensive to make.

Advantages and Disadvantages

Advantages of LGA

Higher Pin Count: Suitable for devices requiring complex connections.

Easy Inspection: Visible contacts provide easier inspection and test of the connections.

Better Mechanical Support: Pins offer better mechanical support, reducing the possibility of damage upon handling.

Lower Cost: Generally inexpensive to produce, thus applicable for cost-sensitive applications.

Disadvantages of LGA

Limited Density: Since pins take up a larger area, the possible number of high-density interconnects is reduced.

Solder Joint Fatigue: Over a certain period of time, solder joints in a package undergo fatigue due to thermal cycling and vibration.

Difficult to Repair: When the pins are damaged, they are not accessible for easy repair.

Limited Thermal Performance: Heat dissipation surface area may be reduced when pins are used.

Advantages of BGA

Higher Pin Density: Allows high-density designs for those components that require a lot of connections.

Improved Thermal Performance: Provides better and more uniform heat transfer, which is critical in high-power applications.

Better Signal Integrity: Shorter lengths of interconnects reduce parasitic capacitance and inductance, improving the quality of the signal.

Compact Size: Useful in applications where space is limited.

Disadvantages of BGA

Difficult Inspection: Solder balls not easily visible, hence difficult to inspect visually.

Difficult Repair: Repair or replacement of BGA packages is cumbersome and requires specialized equipment.

Higher Cost: More costly manufacturing process because of additional steps for solder ball attachment.

Solder Joint Reliability: As mechanical and thermal stresses have impacted the long-term reliability of solder joints.

When to Use LGA and BGA?

Use Cases for LGA

Less Pin Count: Applicable for devices with a smaller number of pin requirements where good mechanical support and ease of inspection can easily be provided.

Repairability: As the pin is accessible to be seen, it's easier to repair.

Cost Sensitivity: It can be chosen on the basis of budget-sensitive projects because their manufacturing cost is less expensive.

Input: Mechanical Stability: As it provides better mechanical support, therefore, it is suitable for applications which may be exposed to mechanical stresses like vibration or shock.

BGA Use Cases

High Pin Count: It is best suited in cases where a component requires a large number of interconnections.

Thermal Performance: Applications that require good thermal performance during operation.

Signal Integrity: An ideal solution for circuits or applications where minimum signal interference is needed.

Compact Design: Space-limited applications since its package size is relatively small.

Decision Factors between LGA versus BGA

Pin Count

First, determine how many pins your component needs to use. BGA packages are more suited for high pin counts, while LGA packages are better at lower counts.

Thermal Performance

BGA packages usually offer better heat dissipation and thermal management for highly heated applications.

Signal Integrity

BGA's reduced interconnect lengths make it the ideal package for radio frequency/microwave and high-frequency applications that require high signal integrity since it minimizes parasitic capacitance and inductance.

Mechanical Stability

LGA packages offer better mechanical stability for applications with high mechanical stress, such as those with high vibrations and shocks.

Cost

Consider your budget. Usually, manufacturing LGA packages costs less compared to the manufacturing cost of BGA packages.

Size Constraints

In applications where a design needs to be compact, BGA packages generally have smaller sizes, hence suitable for compact designs.

Repairability

For highly critical ease of repair considerations, LGA packages are best, since the pins can easily be seen and accessible.

Applications in Industry - Case Studies

Telecommunications

In highly dense networking equipment, such as routers and base stations, BGA and LGA packages show regular applications. Different thermal design techniques ensure the products' appropriate functionality and hence their durability.

Automotive

It finds application in automotive electronics like electronic control units, sensors, and infotainment, where robust thermal management solutions maintain optimum performance even in extremely high temperatures.

Aerospace

The latest cooling methods, including heat pipes and liquid cooling, are in use for managing the dissipation of heat in avionics systems and satellite communication equipment to guarantee safety.

Consumer Electronics

Smartphones, tablets, and gaming consoles have small form factors with high computing power, which also drives the need for innovation in thermal solutions to prevent overheating and ensure maximum device performance.

Cases

5G Base Stations: BGA provides an efficient heat dissipation path for high-power beamforming ICs.

High Performance Computing: LGA processors are using thermal pads to conduct heat to liquid cold plates, thereby keeping them in their optimal operating temperatures.

Radar Systems: Stack BGA memory devices with thermal vias support extreme heat fluxes, enabled by thick ground layers in the multilayer board.

Conclusion

Both BGA and LGA packages offer unique advantages and challenges; especially under high-power applications,. Get to know your packaging technology requirements with respect to such variables as pin count, thermal performance, signal integrity, mechanical stability, cost, size, and repairability for an effective selection of the best option in packaging technology. You can keep the problem of heat dissipation under control and improve performance and reliability by adopting proper design solutions for your electronic systems. Ultimately, BGA or LGA depends on which of these diverse range of factors are traded off to best meet your needs for a particular application.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Compared to THT, SMT offers better miniaturization and weight reduction in any electronic application. With the use of BGA packages, high-assembly density, reliability, and improved performance are achieved; on the other hand, this requires a rework and inspection that is not really common. PCBX specializes in the area of advanced SMT and BGA assembly to help drive modern requirements of compact electronic devices.

Ball Grid Array (BGA) components, such as PBGA, CBGA, CCGA, TBGA, and CSP, provide high I/O density, improved reliability, and high-quality electrical and thermal performance. Quality assembly and functionality are assured since advanced soldering and inspection methods are required, like AXI and AOI. Proper storage and handling shall guarantee the performance of the devices.

In the late 1980s, when electronics began to shrink, BGA packaging was developed to integrate more connections within a given area. Today, BGA is widely used with high-connection chips—processors being a good example. BGA uses solder balls at the bottom of the chip to connect it to the circuit board. It provides high density along with good heat dissipation and fast signal transmission, one of the main reasons it is ideal for modern electronics. However, it requires precise techniques of soldering in BGA manufacturing.