Breadboard vs. Protoboard: Choosing the Right Platform for Your Project

Breadboards and protoboards are key prototyping tools in electronics. Breadboards allow for flexible, solderless circuit design, while protoboards provide durable, soldered connections for finalized designs.

Both the breadboard and the protoboard are two of the most critical prototyping tools within electronics that can ensure projects are done both efficiently and successfully. At PCBX, we value both these components for their vital role in circuit design and development. This article is dedicated to providing comprehensive knowledge about breadboards and protoboards, so you can go about your electronic projects with full knowledge.

Historical Background: From Wooden Boards to Solderless Platforms

The word "breadboard" originated, describing a piece of wood on which one slices bread. In the early days of electronics, engineers would use these wooden boards to hold components and wires in place, which gave way to today's solderless boards. Today, the term defines an ingenious piece of equipment that allows one to prototype electronic circuits with ease and speed with no need for soldering whatsoever. On the other hand, the protoboards, or in other words, the prototyping boards, have also evolved to become pieces of vital importance when more durable and permanent circuit designs have to be built.

What is a Breadboard?

Breadboards have become synonymous with flexible and reconfigurable circuit design. Typically made of plastic with a rectangular grid of interconnected holes, they provide a convenient and reusable base for assembling electronic circuits. Each row of holes is electrically connected beneath the surface, allowing components and interconnecting wires to be inserted and rearranged without any hassle. In doing so, a breadboard becomes an extremely useful device, especially in the initial stages of a project needing the design and test of circuit layouts.

Breadboards' Key Features:

Reusability: The design of breadboards allows for multiple uses by making quick changes, testing various configurations without permanent changes. It is very appropriate to be used in teaching and during iterative design.

Solderless Setup: A breadboard is designed to hold components without soldering. It's easy to change and replace any part if needed. It is highly useful for beginners and for temporary setups that require speedy turnaround times.

Component Compatibility: Although designed for through-hole components, sometimes surface-mount devices can also be fitted onto a breadboard with the help of adaptors.

Limitations: Breadboards are limited by capacitance and parasitic inductance, making them unsuitable for high-frequency applications. Their best application is, therefore, in low-frequency circuits where such factors become insignificant.

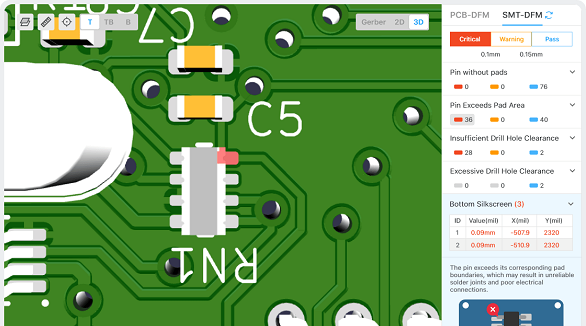

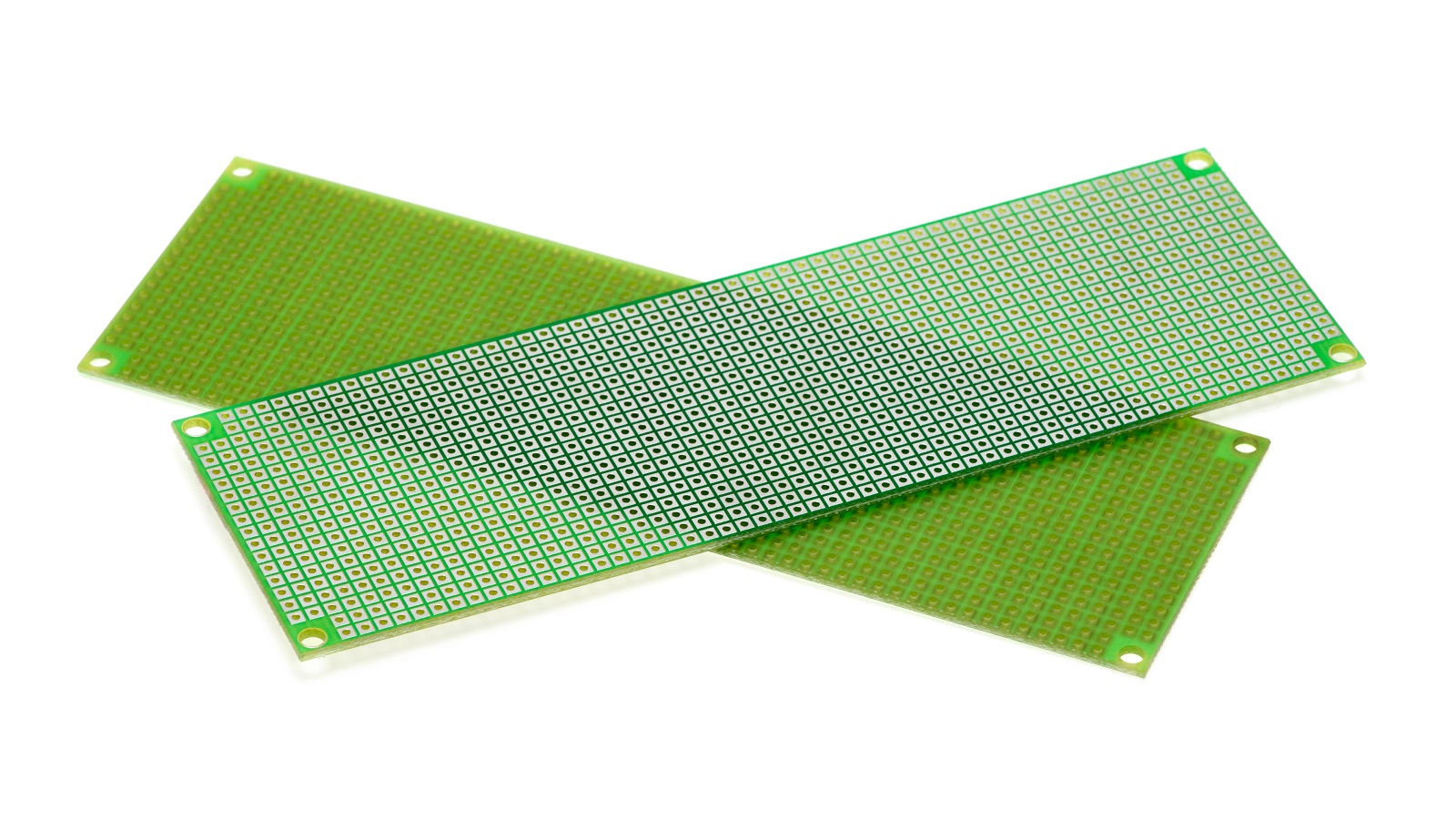

What is a Protoboard?

Protoboards, sometimes also called prototyping boards, offer an avenue to making more permanent and robust electronic circuits. Unlike those of the breadboard variety, protoboards are solder-type; therefore, components must be soldered into place. This creates solid connections that are less prone to the sometimes 'accidental' disconnections possible on a breadboard.

Protoboards- Key Features:

Permanent Setup: Soldering the components provides reliable and sturdy connections, imperative for those prototypes that have to resist mechanical stress or need strong connections.

Versatility: They come in different layouts such as stripboards and perfboards that can accommodate custom circuit paths and layout according to one's needs.

High-Frequency Suitability: Excellent electrical connectivity at reduced noise makes them suitable for high-frequency applications.

Component Flexibility: Both through-hole and many surface mount components can be fitted onto protoboards, being flexible for the varied requirements of projects.

Choosing Between Breadboards or Protoboards

Depending on the nature and requirements of your project, it will help you in deciding whether you need a breadboard or a proto board.

Breadboards:

Ideal for Testing and Iteration: Breadboards are ideal for the testing phase of a project. In a case when the design of a circuit is not frozen as yet, and frequent changes are expected, then breadboards are very handy.

Educational Tool: Breadboards allow learners and educators to create hands-on without necessarily having to solder.

Limited to Simplicity: They are best for simple circuits where the perils of parasitic capacitance and inductance don't impact the circuit's performance.

Protoboards:

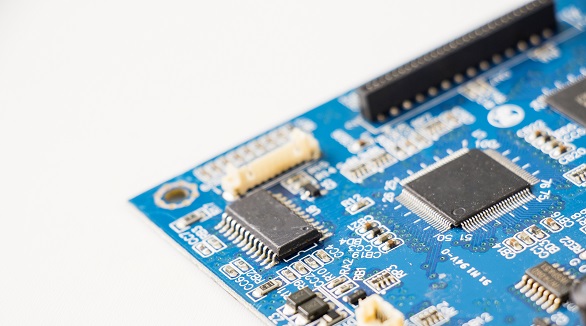

When Finalizing Designs: Once a circuit's design stabilizes and you move towards the creation of a final prototype, the protoboards are superior. Their solid connections are crucial to replicating a production environment.

High-Frequency and Complex Circuits: Where circuits are becoming more complex and/or requiring a higher frequency, the same permanent connections on a protoboard provide reliable and consistent performance.

Durability and Longevity: Projects that should have a long life span, travel, or be environmentally stressed require a robust solution and benefit from using a protoboard.

Going from Breadboards to Protoboards

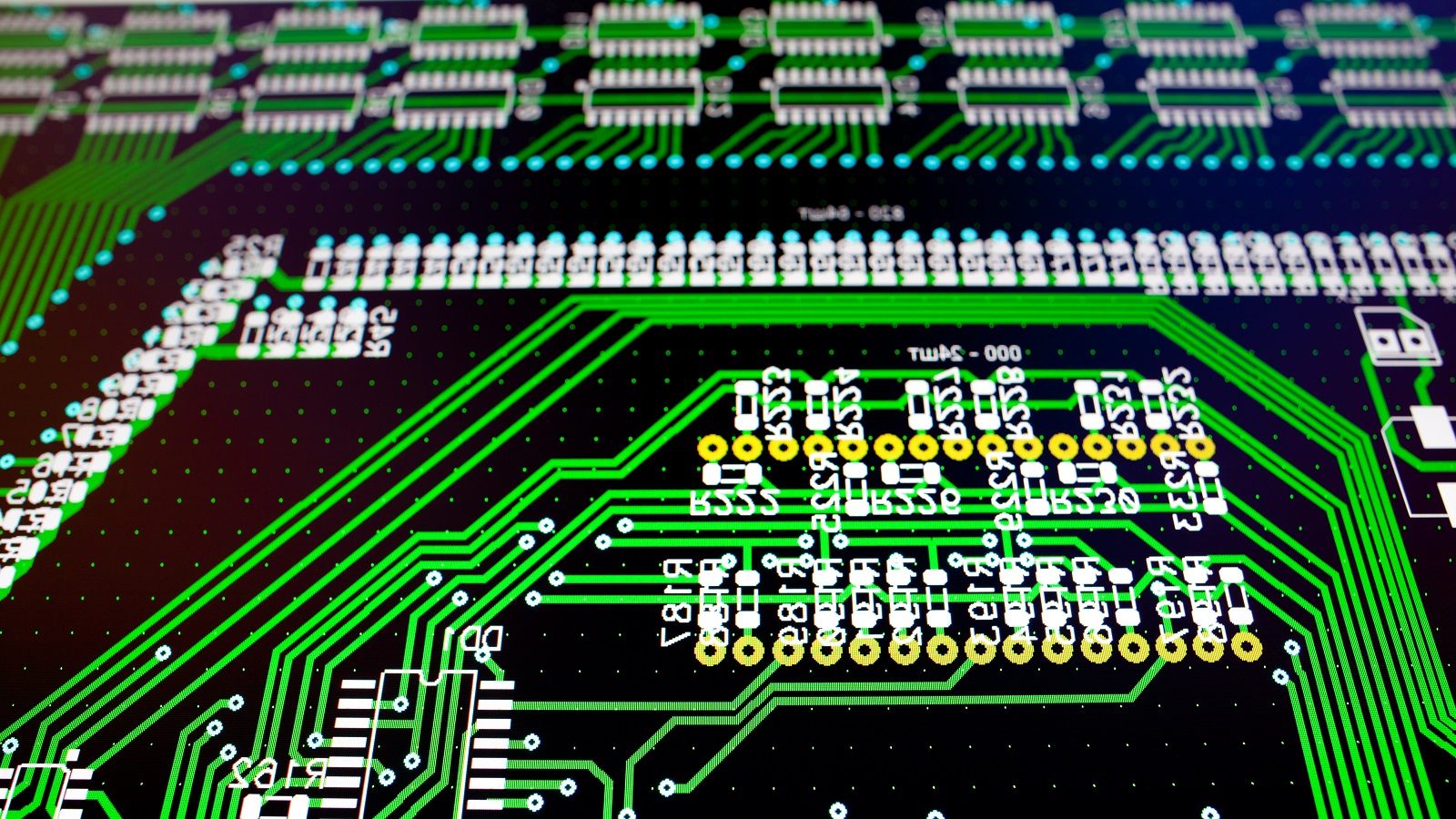

The standard path for an electronic circuit in design goes from breadboard to proto board. This path indicates the maturing of the design from one easily changed into one that is rather fixed and final.

Steps in Transition:

First Design on Breadboard: Begin the work on laying out a circuit on a breadboard. This initial phase is especially critical for experimenting with component connections and configurations, debugging problems, and refining operating features.

Refinement and Testing: The breadboard will be utilized in refining the design of locating the faults and testing all the elements to ensure they work as intended. In this stage, multiple iterations are very likely to be required.

Finalization and Permanency: If happy with the design created, the circuit is replicated onto a protoboard. This consists of carefully soldering to create permanent connections, hence making the circuit durable.

Improved Reliability: Transitioning to a protoboard will also mean enhanced mechanical robustness, while electrical reliability increases on account of reduced contact resistance and parasitic issues.

Conclusion: Optimizing Your Electronics Prototyping

Which one to choose-a breadboard or a protoboard-is related to the specific requirements and other issues of your project. In terms of flexibility and ease of use when there is a question of the prototyping phase, breadboards are unparalleled and thus ideal for testing and educational purposes. Protoboards provide permanence and reliability required in designs that are already finalized, especially when high-frequency performance is an issue.

We in PCBX believe your journey through prototyping to design requires guidance and equipping enough to assure success. Be it early varieties of testing or ready to go into a permanent setup with a protoboard, we provide you with the necessary toolsets and experience for bringing electronic circuits into being accurately and effectively.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.