Capacitor Polarity in PCB Design

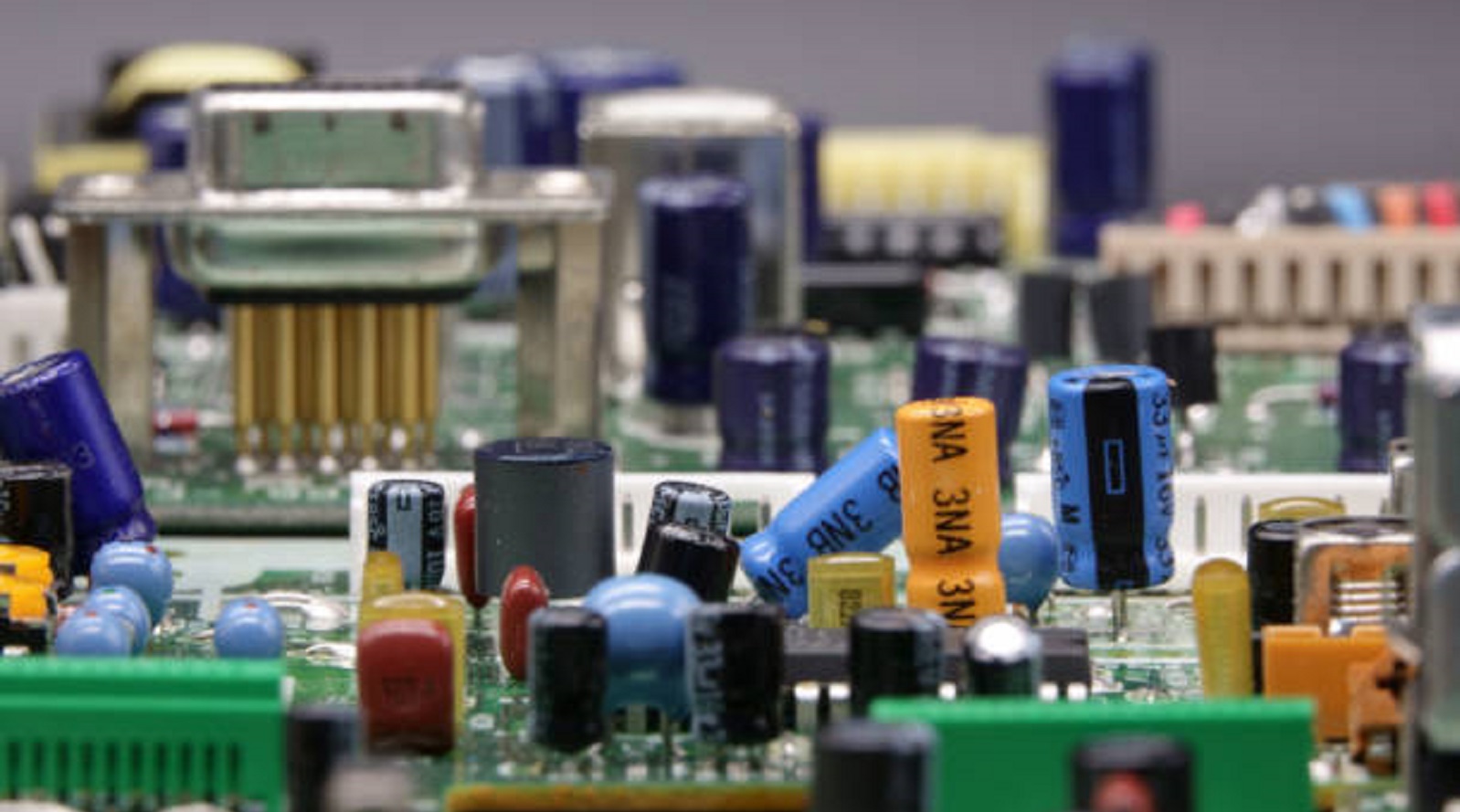

Capacitors are crucial in PCB design for filtering and timing. Correct polarity in electrolytic and tantalum types prevents malfunctions and ensures reliability.

Capacitors play an indispensable role in the complex world of printed circuit board design and assembly; they store and release electrical energy, finding central applications in many functions such as filtering, coupling, and timing across many applications. However, the most critical factor which often needs to be brought out with due care is capacitor polarity. Understanding and applying correct capacitor polarity is essential for both circuit reliability and to prevent component damage or even catastrophic failure.

The polarity of a capacitor is related to the fact that some sorts of capacitors have explicit positive and negative terminals. Those indicate the way a capacitor should be connected to a circuit. Failure in keeping polarities usually ends with the most severe malfunctions, like the breakdown or explosion of a capacitor. Polarized capacitors are electrolytic and tantalum types of capacitors that need to be connected in accordance with their polarity: the plus sign toward the higher voltage, and the negative toward the lower voltage in the circuit. On the contrary, non-polarized capacitors are ceramic and film types without polarity designation; thus, these can be connected in any direction without adverse effects.

Types of Polarized Capacitors

Electrolytic Capacitors

Electrolytic capacitors are used in point-to-point wiring and in applications requiring high capacitance values in relatively small package sizes. They are very common in many power supplies and audio circuits, among others. Electrolytic capacitors use a liquid or gel electrolyte within the package to achieve a high capacitance value and are, therefore, polarized. The polarity is usually indicated by a "+" sign marking on the positive terminal, while the negative terminal is often denoted by a "-" sign or stripe. Incorrect reversal of these terminals can lead to overheating, leakage, and even dangerous explosions. That is why it requires very precise installation.

Tantalum Capacitors

Because of their great stability, reliability, and resistance to voltage spikes, tantalum capacitors are in great demand. Due to this fact, they are very useful both in mobile and computing electronics. Like electrolytic capacitors, they are polarized, with the positive terminal clearly marked, usually by a "+" sign. Incorrect polarity applied to tantalum capacitors can also lead to component failure or leakages, making correct identification and connection critical.

Non-Polarized Capacitors

Ceramic Capacitors

Ceramic capacitors possess very good performance characteristics for high-frequency applications. Because they are non-polarized, their installation either way produces negligible errors in installation, so they have gained quite a wide range of application fields suitable even for signal filtering and RF. Ceramic capacitors also demonstrate stability over huge variations in temperatures and are available in an immense range of values.

Film Capacitors

Film capacitors have excellent stability and efficiency for a wide range of voltages and frequencies. The non-polarity nature of these capacitors makes them perfect for a number of applications, including audio circuits and power supply systems. These are made from plastic film dielectrics and give reliability when used in the environment where consistent performance is required.

The Importance of Observing Capacitor Polarity

It is critical to observe capacitor polarity due to the following reasons:

Performance Integrity: Polarized capacitors may degrade in performance, leak, and lose capacitance when reverse polarities are applied. Such performance may change drastically in circuit operation and result in the device not working as intended.

Safety Concerns: Badly oriented electrolytic and tantalum capacitors may fail by explosion or leakage. These failures may cause adjacent component damage and result in safety hazards involving high voltage or large capacitance.

Reliability Assurance: Correct polarity avoids overvoltage conditions, which will protect the dielectric integrity of the capacitor, and enhance the component's lifetime. Such assurance is paramount for the overall reliability and durability of electronic devices.

Identifying Capacitor Polarity

Polarity identification before installation is one of the main ways through which capacitors are identified:

Markings: Explicit "+", "-" signs are marked on capacitor bodies. In electrolytic capacitors, sometimes a stripe on the canister designates the negative terminal.

Lead Length: Most through-hole capacitors have one lead for positive longer than for negative. It acts as physical polarity.

Referencing Datasheets: Datasheets offer comprehensive information on capacitor specifications, including polarity, capacitance, and voltage ratings.

Multimeter Testing: A multimeter provides the facility of testing polarity; one would switch to continuity or diode test mode to confirm which terminal is positive and which negative.

Common Applications

Power Supply Circuits: Polarized capacitors are crucial in smoothing and filtering voltage outputs with a view to enhancing stability and reducing noise interference.

Audio Systems: Capacitors are used in blocking DC offsets in audio signals, with strict polarity so that the signal quality and integrity will be maintained.

Timing Circuits: In oscillator and timing applications, capacitors control frequency parameters. For precision in timing, this must be accurately installed.

Capacitor polarity is a very basic yet important conceptual factor in PCB design and electronic assembly. Proper understanding of polarized capacitors, such as electrolytic and tantalum types, and their appropriate applications are quite crucial to avoid degradation in performance and safety, or even failure of the component parts. That means stating the importance of making capacitor choices match applications and checking polarity during installation, which we at PCBX take seriously. Observance and respect of capacitor polarity will enable designers and engineers to protect their circuits' reliability and efficiency, hence successful and long-lasting electronic products. It helps in maintaining excellence in a wide array of applications and is the commitment of PCBX towards excellence in PCB manufacturing and design solutions.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

The 3.3K resistor is vital in electronics for current regulation, is widely available, and ideal in precision circuits, ensuring stability and cost-effectiveness.

Capacitive circuits store and release energy, stabilize voltage, filter signals, and manage power flow, making them vital for modern electronic systems.

eFuses are advanced PCB fuses that reset automatically, offering fast, precise protection and versatility in electronics, enhancing device safety and reliability.