Cold Solder Joints in PCB Assembly

Cold solder joints result from improper soldering, impacting PCB performance. Detection and prevention via proper technique and equipment ensure reliability.

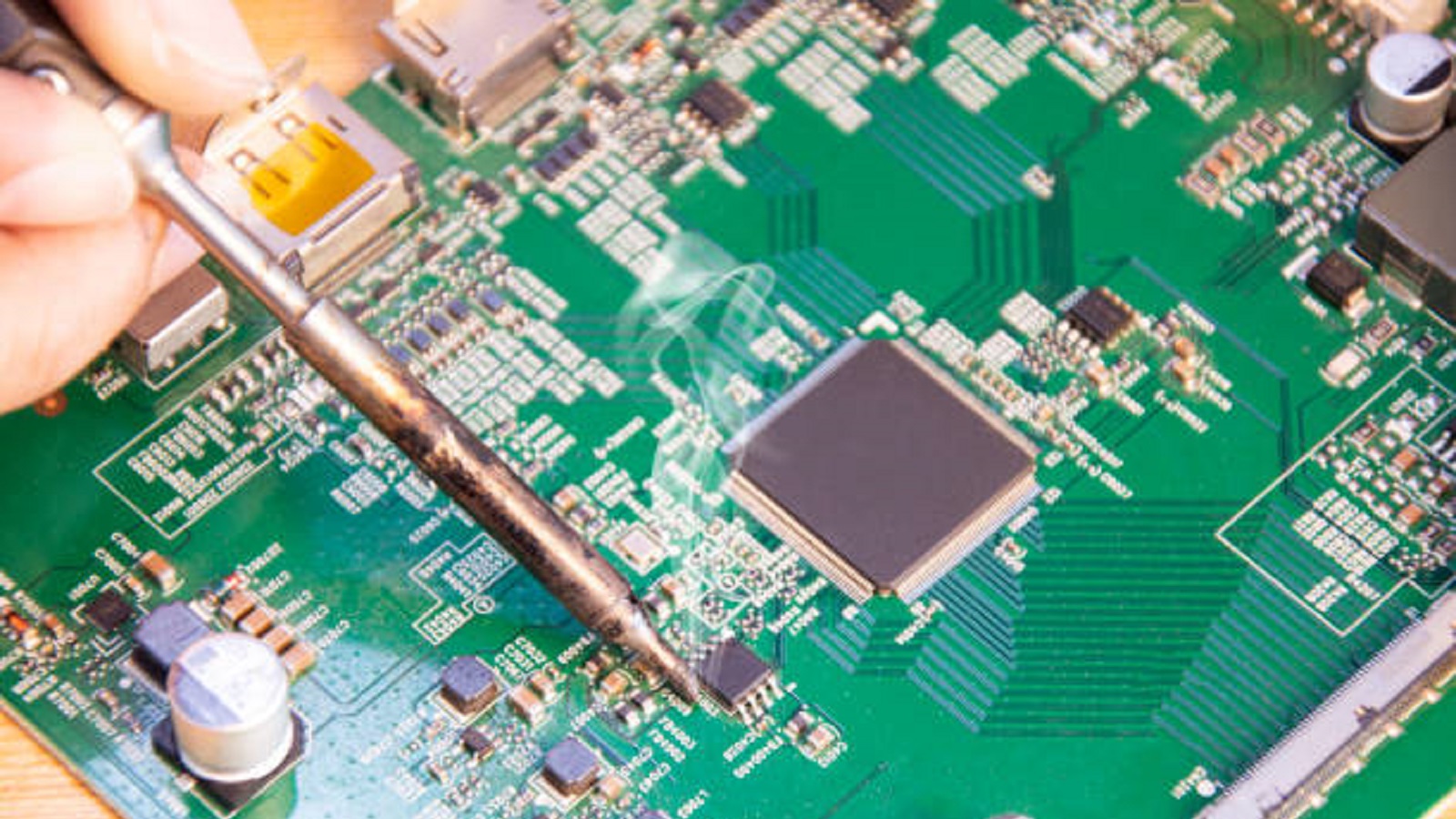

Soldering is a very critical process in the world of printed circuit board assembly, as this provides the means by which electrical components are securely attached to the board. Using a mixture of Tin, Sn, and Lead, Pb, or a lead-free alloy when answering the demands of today's environmental requirements, soldering is thus done with SMT or with THT. Apart from being such a fundamental process in the manufacture of PCBs, soldering is not without its problems, and cold solder joints are probably its most common and troublesome defect. This article examines the nature of cold solder joints, along with their identification, causes, and methods to avert them, thereby safeguarding the reliability and performance of PCBs.

A cold solder joint occurs when the solder has not melted sufficiently or solidified too quickly and thus fails to make a proper electrical contact. These kinds of joints are usually marked by a dull and grainy appearance, other than the shiny concave surface they should display, angled between 40 and 70 degrees from the horizontal. Cold solder joints critically implicate the functionality of a PCB and make for poor performance with increased costs because repairs or replacements will be inevitable.

Causes of Cold Solder Joints

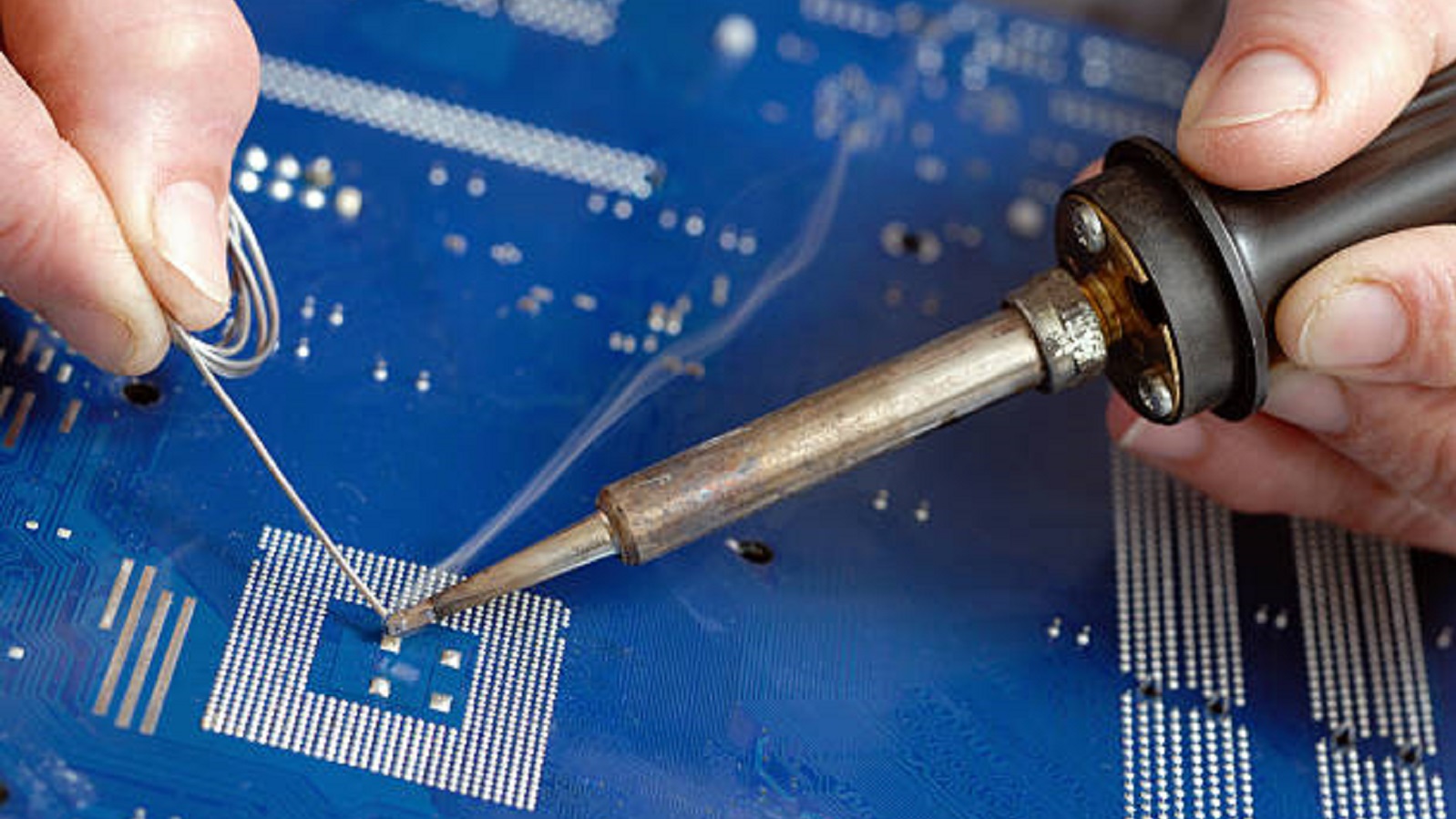

Insufficient Heat: The single major cause of cold solder joints is not applying adequate heat due to either a very poor quality soldering iron or an incorrectly adjusted temperature. The risk mentioned above is greatly reduced if a temperature-controlled soldering station has been used.

Contaminated surfaces: The PCB pads and component leads should be free from dirt or oxidation, which could interfere with the adhesion of the solder and prevent it from forming a solid connection.

Disturbances while cooling down: Motions of the PCB or of the components when the solder is molten may cause disturbed or cracked joints. Such an event damages mechanical and electrical integrity.

Insufficient or Incorrect Solder Alloy: Using solder with the wrong melting temperature, or alloy composition considering the materials being used, cannot provide a proper bond and cool-down.

Excessive Reflow: Continuous heating cycles or additional heat exposure can degrade the overall quality of the joint over time.

Types of Cold Solder Joints

Distributed Cold Joint: These occur when there is movement during soldering, leading to concave deposits. Often, this will not allow a bond to take place properly. Risk could be reduced by stabilizing the PCB with a vice or holder while soldering.

Cracked Solder Joint: Mechanical stress or lack of solder can cause joints to break, especially in heavier or vertically mounted components. Cracked joints may not be cold joints at first, but over time may become one if neglected due to deteriorated performance.

Dry Solder Joint: These occur because of insufficient solder leading to open circuits or electrical resistance. The quantity of solder, while assembling them, has to be ensured cautiously to avoid the generation of such joints.

Cold Solder Joints Detection

Early detection of cold solder joints is necessary to ensure the defects are repaired before malfunctioning of the device:

Visual Inspection: Conducting thorough visual checks with magnifying tools can reveal dull, uneven joints. Light passing through a joint signals weak bonding.

Multimeter Testing: Employ continuity tests to check for uninterrupted electrical pathways at the joint. Resistance testing further confirms the joint's integrity, with anomalous readings indicating potential cold solder issues.

Preventing Cold Solder Joints

Use of proper equipment: Utilize good-quality soldering stations with temperature control features. In any form of soldering, consistency is the perfect heat application.

Surface Preparation: Ensure all components to be soldered are free from contaminants for better solder flow and adhesion.

Appropriate Solder and Techniques: Choose the solder alloys that suit the application properly and exercise steady technique so the joint is not disturbed during cooling.

Environmental Control: Keep work areas free of vibrations and external temperature fluctuations that might affect the flow of solder and cooling of solder.

Adequate Application of Solder: Apply adequate solder in a proper manner, not too wet or without enough solder, since the quantity of solder may vary for each joint.

Avoid Over-reflows: The joints must be exposed to the minimum heat cycles possible to prevent degradation over time.

Training and Experience: Experienced technicians develop an understanding of the right techniques and cues that denote conditions for perfect soldering, and they are less likely to form cold solder joints.

Cold solder joints are one of the major challenges in PCB assembly. If unresolved, they can compromise the performance and reliability of electronic equipment. By identifying the causes, manufacturers can identify appropriate prevention measures that will help them improve the quality and reliability of printed circuit boards.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Ensure PCB longevity by optimizing solder materials, protective coatings, and handling to meet industry standards and withstand extreme conditions.

Solder masks protect PCBs, while paste masks aid precise component placement during assembly, both crucial for PCB reliability and efficiency in electronics.

The article provides a step-by-step guide to soldering a PCB, covering workspace setup, essential tools, and safety measures. It explains heating the soldering iron, applying flux, tinning the iron tip, placing components, heating joints, applying solder, cooling, inspecting, and cleaning. Emphasis is on practice and safety for successful soldering.