Differences Between ARM and FPGA Processors

ARM processors are efficient and flexible, ideal for many applications, while FPGAs offer custom parallel processing, crucial for specialized tasks requiring flexibility.

Effective system design depends quintessentially on the selection of the right processor since the field of electronics keeps changing day by day. ARM and FPGA are two types of processors with very different architectures that cover a broad spectrum of applications. For this reason, for a PCB designer, such knowledge is quite significant in selecting the appropriate processor based on specific application requirements. This analysis examines in greater detail the architectural subtleties, performance features, and applications of ARM and FPGA processors so that developers can make informed decisions.

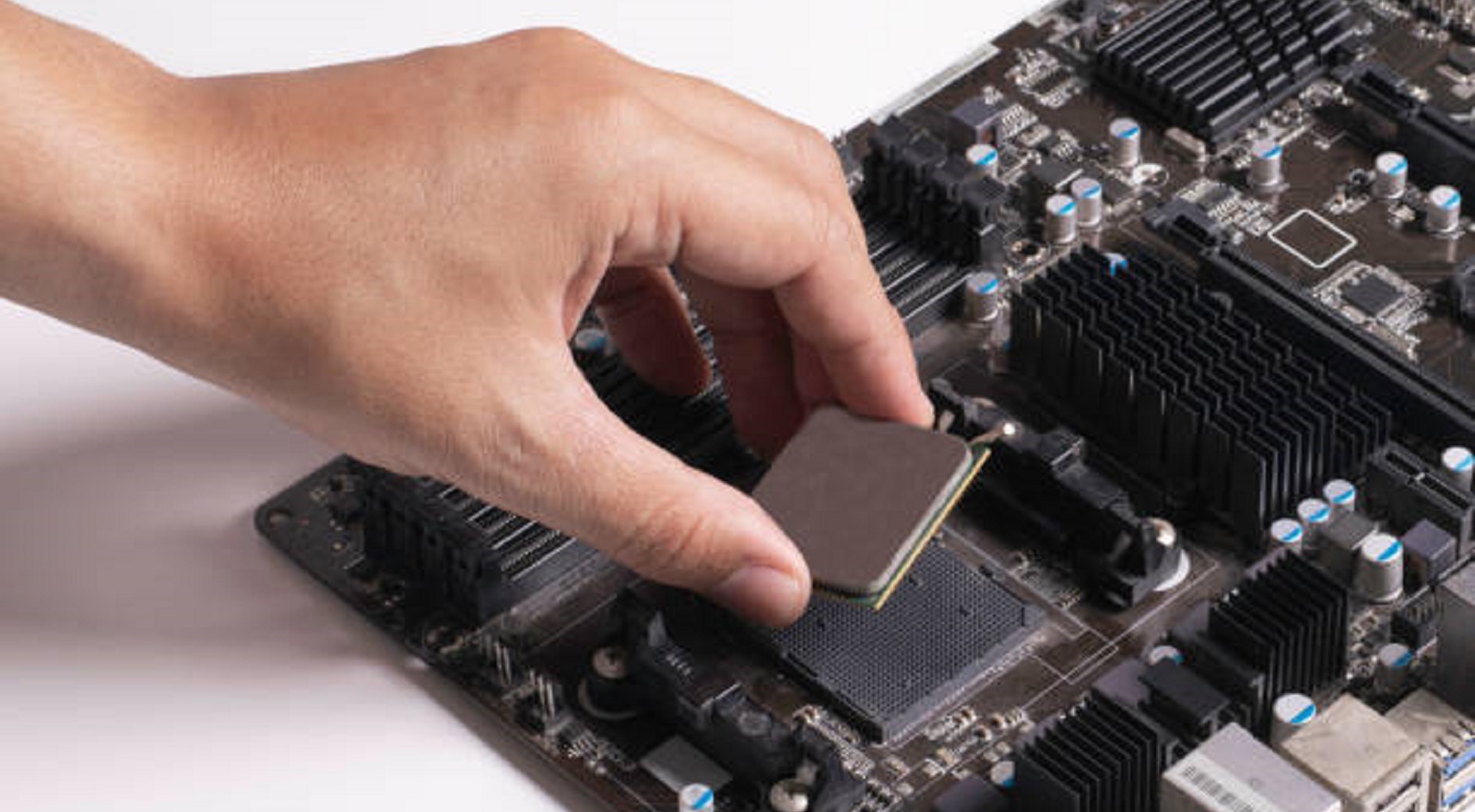

ARM Processors

ARM processors denote efficiency and flexibility. The ARM processes under RISC architecture: it has reduced the instruction set complexity, and its instructions can be executed in a single clock cycle. That brings in processors designed for the lowest power consumption and cost-effectiveness. In the modern world, where energy efficiency is at its pinnacle, ARM is ahead because of the ability to provide strong performance without energy draws or heat generation.

Scalability is another feature of ARM. From microcontrollers for simpler, everyday devices to application processors in smartphones and tablets, there are examples indicating that performance requirements can be fulfilled in different sectors with ARM processors. Besides others, technology giants Qualcomm, Samsung, Nvidia, AMD, and Apple are working on ARM-based chips for various applications-thereby underlining the adaptability and acceptance of the architecture.

Key Features of ARM Processors

RISC Architecture: Simple; fast execution of simple instructions.

Energy Efficiency: Low heat dissipation; hence, suitable for portable and battery-powered devices.

Scalable Performance: Applicable to a wide range of applications, from microcontrollers to high-performance processors.

Development Environment: Software-oriented, generally using C/C++ and Assembly languages.

All the above factors have positioned ARM to become the powerhouse for billions of devices ranging from consumer electronics to industrials.

FPGA Processors

Unlike ARM processors, Field Programmable Gate Arrays present a completely different proposition with a reconfigurable architecture. An FPGA does not have a logically predefined framework; instead, it is composed of a matrix of configurable logic blocks connected by programmable interconnects. The structure allows a user to decide the hardware configuration even after its production is completed because some applications require specific processing capabilities or functionalities.

FPGAs shine in roles demanding high parallelism and custom data processing. The tasks that include digital signal processing, machine learning, image processing, or hardware acceleration are good candidates for FPGAs due to their parallel capability of processing several data streams simultaneously. Such flexibility does, however, require hardware description and configuration details usually implemented using HDLs like Verilog or VHDL. This is the level of hardware-level programming, which gives much more flexibility than what software can provide but needs a considerable amount of knowledge of digital logic.

Key Features of FPGAs

Reconfigurable Logic: Can be tailored to specific application requirements, even post-manufacture.

Parallel Processing: Optimized for concurrent data flows.

High Performance: Ideal for applications requiring intensive computational tasks.

Hardware Description Languages: Using Verilog or VHDL, design can be done at this level with good control over the functionality of the hardware being designed.

Though FPGAs are not as ubiquitous as ARM processors, their strong customization and parallel processing capabilities are very useful in niche domains.

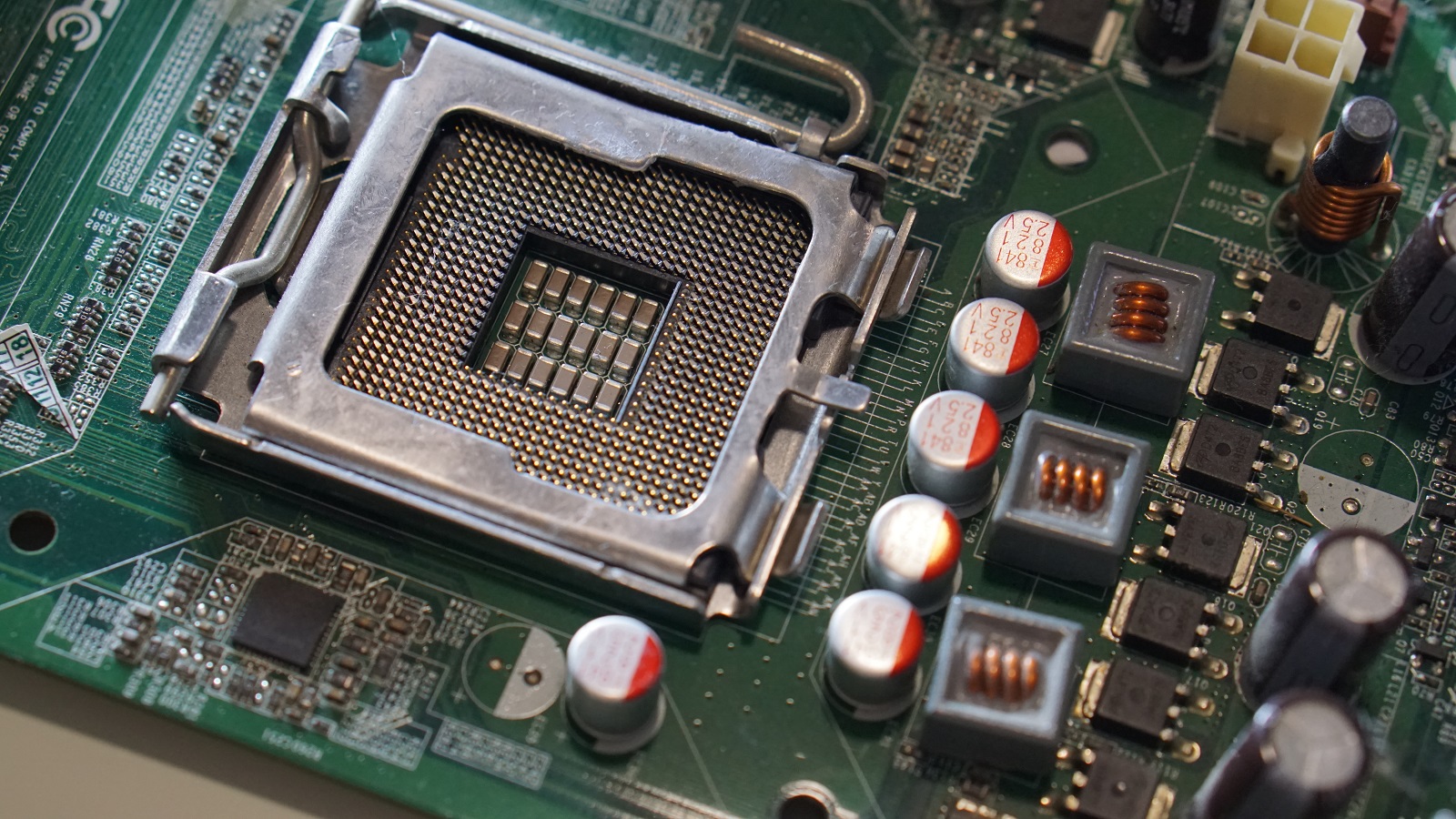

Architectural Differences

The main philosophical differences between ARM and FPGA processors show in their architecture and implementation. In ARM, there is a RISC architecture of fixed hardware logic optimized for software instructions that may be executed most efficiently. Therefore, ARM's systematic approach gives it suitability in maintaining consistent performance across different applications of general use.

In stark contrast, FPGAs offer a reconfigurable fabric, so their internal hardware can be restuctured as needed. This allows for a wide variety of custom applications, especially where a parallel data flow architecture is necessary to perform tasks in parallel. Such flexibility enables FPGAs to achieve performance that would be impossible using conventional processor designs for some specialized application.

Performance Attributes

ARM and FPGA processors have incredible performance but their approaches vary significantly. ARM-based processors have followed the sequential execution strategy where tasks are done in an ordered, linear way. Sequential execution natively reduces concurrency but is great for high single-thread performance up to 3 GHz. The strong power management further strengthens this, giving ARM an early lead when it comes to energy efficiency of mobile and embedded applications.

FPGAs are designed for parallelism. Operating at typically lower clock speeds, around 100-400 MHz, they shine in processing high volumes of data in parallel across custom pipelines. This makes them very effective for computationally intensive tasks like encryption and image processing, where throughput is the name of the game.

Programming Paradigms

It's fundamentally different between programming for ARM and FPGA. ARM processors are programmed using a high-level software language like C/C++ and Assembly, which abstracts away the messy details of hardware, making development easier due to well-established frameworks and tools in the world of software engineering.

But on the other hand, FPGAs demand that the designer understand and manipulate hardware at a very fine level using hardware description languages like Verilog or VHDL. An FPGA application requires creating custom circuits and logic pathways, which, in turn, requires deep knowledge of digital electronics. In general, therefore, developing an application on an FPGA has a more rapid learning curve but offers unparalleled flexibility to customize hardware functionality to application-specific requirements.

Applications

Both are suited best for different types of applications owing to their unique capabilities. ARM suits well for the development of mobile phones, embedded systems, and IoT endpoints because of their energy efficiency and scalability, both standardized and efficient computing become an easy job. On the other hand, FPGA can be done well in conditions that need high parallelism and hardware customizations. Data centers, cloud accelerations, highly developed computer visions, and even autonomous vehicle technology require these chips.

The architectural difference in ARM and FPGA processors comes into view for two broad uses: first, there is ARM with its power-efficient, flexible processor used everywhere in consumer and industrial applications, while on the other hand, there are FPGAs with unique capabilities of customization and processing, highly demanded in a specific domain of operation. Understanding the strengths and weaknesses of each is critical when choosing the processor best suited to a particular application to optimize its performance and efficiency according to what the application calls for. And this is precisely the point when it comes to successful system architecture: processor selection depends on the need of a particular application.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

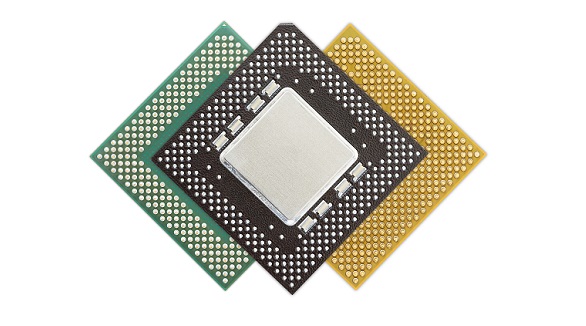

BGAs offer efficient, reliable IC connections with superior performance, comprising seven types ideal for high-performance electronics, optimizing space and thermal efficiency.

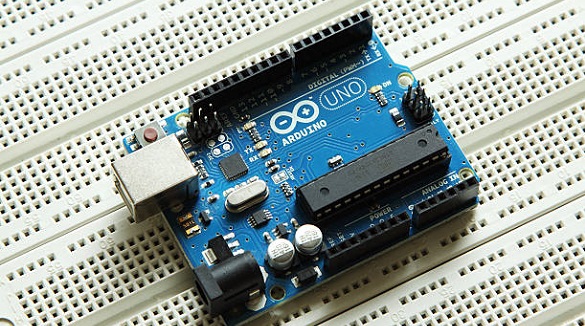

FPGAs with Arduino, like MKR Vidor 4000, enhance electronics prototyping with high flexibility, real-time processing, and customization for diverse applications.

IC packaging is essential in electronics for protecting components, providing electrical connections, and managing heat. This tutorial explores its complexities, including its importance, various types like SMD, QFP, and BGA, and considerations for choosing the right package for specific applications. Proper IC packaging enhances PCB performance and reliability.