Differences Between FPGA and CPLD

FPGAs offer high flexibility and capacity for complex designs, while CPLDs provide simplicity and cost-effectiveness for smaller applications, crucial in PCBs.

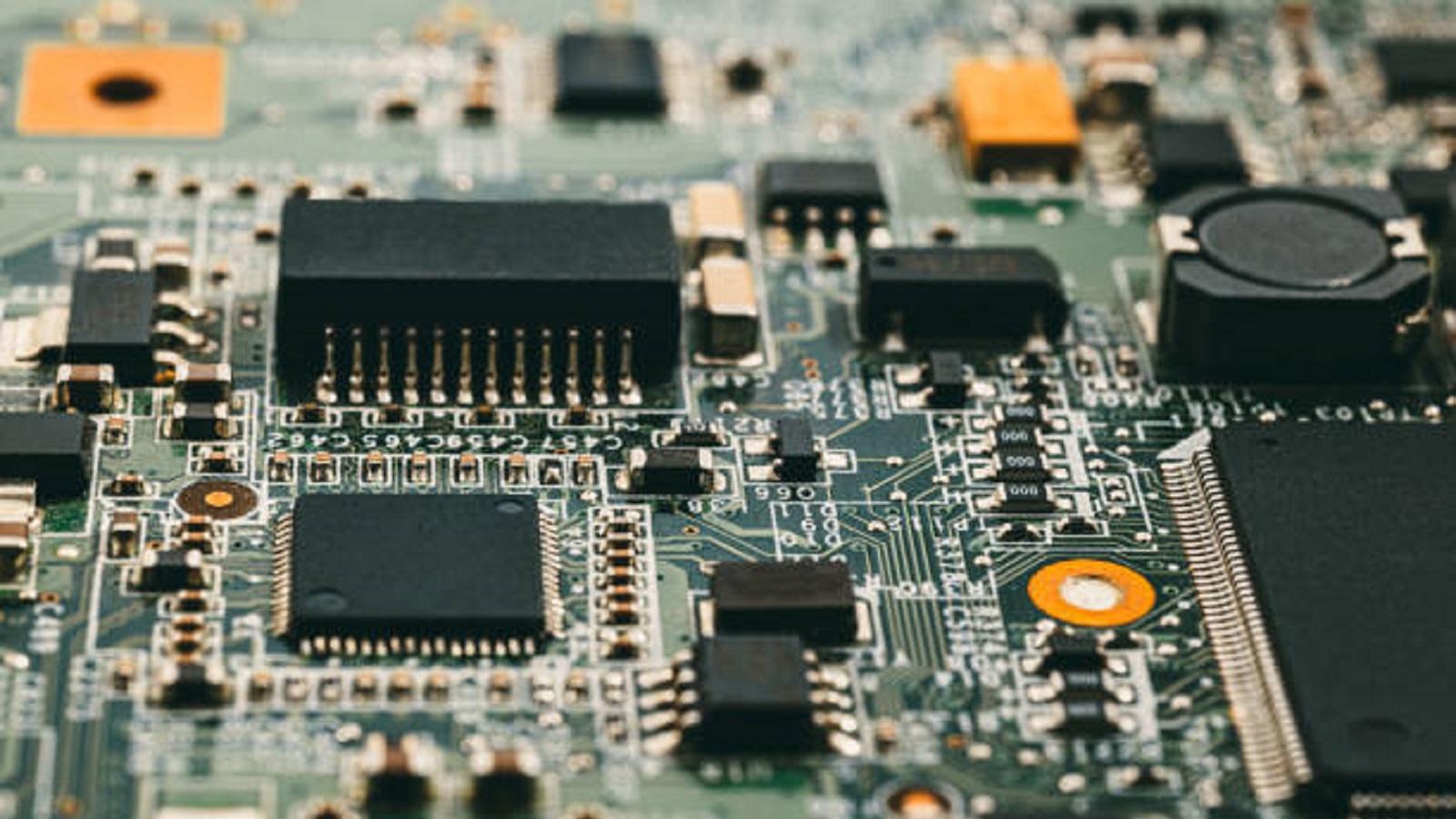

In the world of electronic design, that is rapidly changing, FPGAs and CPLDs stand out as crucial components, extending unparalleled flexibility and customization. Each brings key capability and features, making one more suited than the other for particular applications. Understanding the complex differences that exist between these two will greatly affect design choices, especially for printed circuit boards, where these devices find common placement. Here, we look into these differences to help engineers with their digital circuit implementations.

FPGA

Architecture and Capacity

Basically, FPGAs are blank canvases of logic that are configured post-manufacturing. Being made up of a grid of programmable logic blocks, FPGAs are reconfigurable interconnects that tie the logic units together closely, thus allowing them to implement anything from simple AND/XOR logic to advanced signal processing. Some key aspects of FPGAs include:

High Logic Capacity: Hundreds of thousands to millions of logic gates are achievable in one device.

Reconfigurability: The designed circuits can be continuously refined and adjusted long after deployment.

Parallel Processing: It efficiently handles large-scale data processing jobs.

Features highlighted: Its distinct DSP slices speed up mathematical calculations.

Applications

The sophisticated and versatile architecture of FPGA leads to a wide range of applications, including:

Digital signal processing: Due to parallelism, FPGAs are an excellent option for applications requiring a lot of computing, including real-time video processing.

Aerospace and Defense: Applications requiring real-time data analytics and encryption make good use of the re-programmability and robustness of FPGAs.

Prototyping: In many cases, prototype variants of ASICs and SoCs are made using FPGAs for the purpose of testing the logic before tapeout.

CPLD

Architecture and Functionalities

On the other hand, CPLDs have a more predictable structure and are less complicated. Each of its limited number of macrocells is capable of realizing a logic function with a medium level of complexity. Although a CPLD's switch matrix is less 'flexible' compared to an FPGA's network, it is predictable in timing, too, because

Bound Logic Capability: Ranges from a few hundred to a few thousand logic gates.

Predictable Performance: Due to a macrocell-based architecture offering uniform behavior.

Non-volatile programming: uses no external power to store settings upon reset.

Applications

CPLDs' reliability and simplicity make them ideal for the following applications:

Control and Interface Logic: Glue logic applications that need to be consistent. Cost-sensitive designs are those that employ low-cost components and extremely cheap logic solutions.

Compact, Lower Power Devices: those sensitive to small form factors, very common in consumer electronics.

FPGA vs. CPLD

Logic Capacity and Flexibility

Where FPGAs do provide enormous capability in complex, custom architectures and are replete with abundant high-density resources for logic operations, the CPLDs are much more limited but much more efficient for the less complex implementation of logic. FPGAs have complex routing as compared to fixed but dependable interconnect system of the CPLDs.

Design Tools and Methodology

Even with such high granularity provided for detailing minute specifics about the operation and logical structure, most of the FPGAs are closely aligned with their logic programming using hardware description languages, such as VHDL or Verilog. However, CPLDs employ a far more direct and simplified equation-based logic programming technique.

Performance Attributes

Because of their integrated memory configurations and robust connections, FPGAs are more appropriate for applications requiring high levels of parallelism. Due to their comparatively simple structure, CPLDs frequently consume less power and are able to perform more regular tasks at predictable times.

Aspects of Economics

Because CPLDs are simpler than FPGAs, they are often less expensive, especially when logic capacity requirements are modest. On the other hand, the bigger the financial investment in an FPGA, the more features and performance it offers.

Clock Management and Development Tools

The system design using FPGAs has complex clock management and is hence capable of multiple independent clock domains. This capability is highly helpful for designs that employ high frequencies. CPLDs provide enough consistent performance for applications with less precise timing requirements, despite their larger constraints.

Selecting Between FPGA and CPLD

Choose FPGAs for:

The best applications for FPGAs are in designs where:

Several gates are employed in complex configurations.

applications with a lot of memory bandwidth and high performance.

designs with several fast interfaces and sophisticated DSP features.

HDL-centric design that is flexible, with powerful debugging.

Choose CPLDs for:

When the cost and compactness is important for the designs requiring only simple control logic or interface.

It takes relatively little power and is small enough to fit in a small container.

Using logic formulas to define designs is easy.

Designing a PCB incorporating FPGAs or CPLDs requires consideration of temperature, power management, and limited space. As much as FPGAs grow in power and complexity, they demand techniques for dissipation and advanced power distribution. CPLDs can serve more compact applications, with lower scales of a PCB assembly due to the less demanding nature of the architecture.

Thus, FPGAs and CPLDs together provide very important solutions for programmable logic needs and are each the best in their respective domains. FPGAs allow applications requiring complex logic, with capabilities of dynamic reconfiguration, while CPLDs find their niche in less demanding, low-cost solutions. Electronics engineers, once conversant with their differences and relationship to performance and cost, would be well-equipped in making design decisions that would create an optimal solution for functionality in application-specific contexts.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

SMT assembly streamlines electronics manufacturing with compact, reliable designs using precise equipment, meeting high-density demands and international standards.

PCB recycling is vital to reduce environmental hazards and recover valuable materials, especially copper. Effective methods include mechanical, chemical, and thermal processes, significantly benefiting sustainability.

Capacitors are crucial in circuits for storing energy. Testing methods include in-circuit and out-of-circuit using digital multimeters, ESR, and LCR meters. Proper testing ensures reliability and prevents malfunctions.