Electronic Module Assembly

Electronic module assembly is crucial for innovation, driven by demands for high-performance, reliable modules in fields like connectivity and electric transportation.

Within the framework of today's fast-growing world of technological development, electronic module assembly plays a significant role in innovation-enabling roles that emanate from such key megatrends as connectivity, electric transportation, and renewable energy sources. New technologies are continuously pushing up the demand for modules that offer unparalleled performance and reliability. In turn, demands have brought about changing and adapting processes. This article updates the present status in electronic module assembly, underlining its economic importance in modern technology.

Electronic modules represent compact units integrating a variety of electronic components to perform specific functions within larger systems. They can form the very basis for everything, from automatic vehicle transmissions and industrial control to consumer electronics. For instance, in automotive applications, the electronics modules can package all the transmission control electronics into one unit to control hydraulic valves for gear selection. This, in turn, improves not only the system reliability by reducing component count but also reduces the overall system weight, which is an important factor in automotive design.

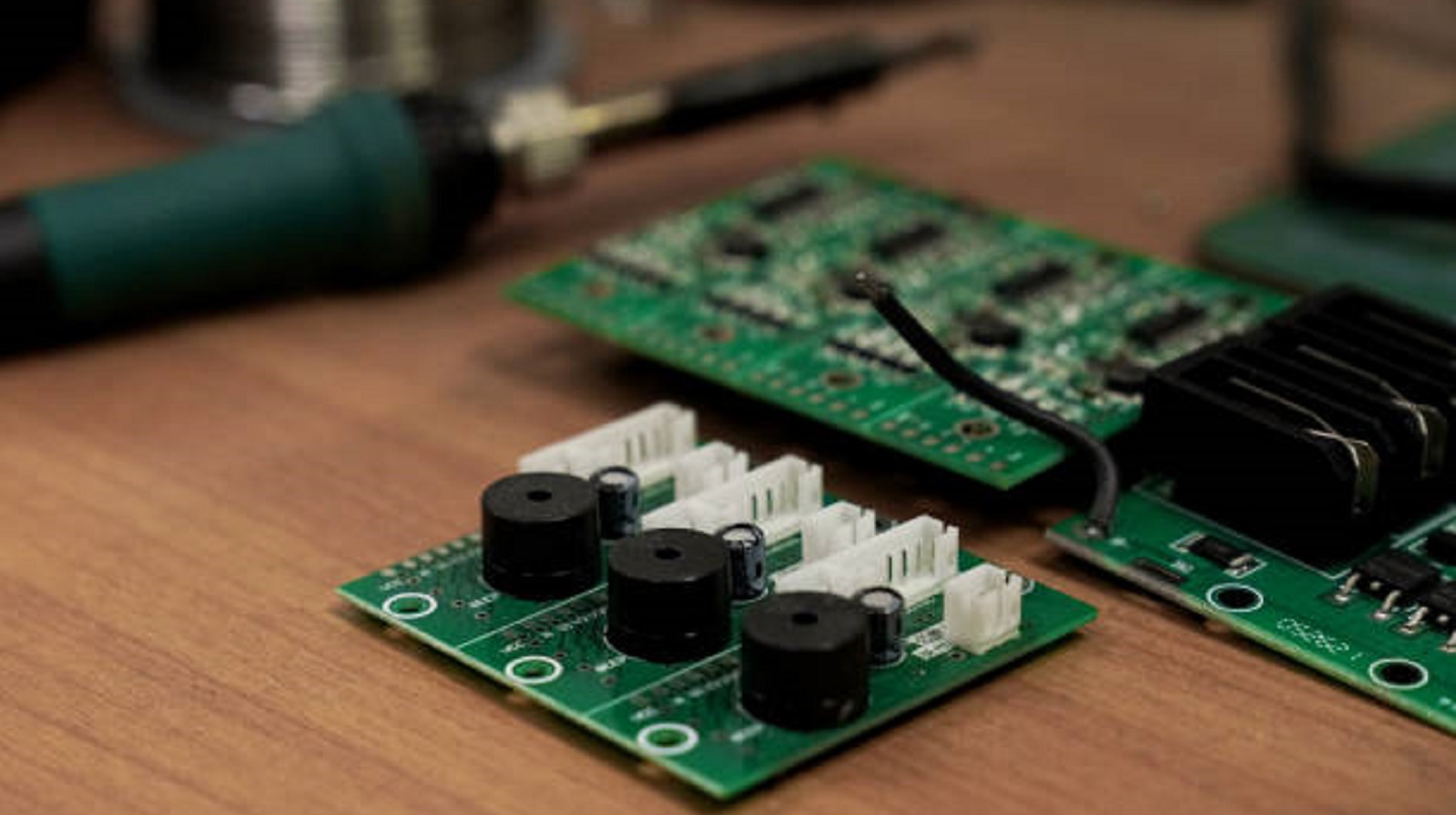

Assembly Techniques: Embracing Advanced Technologies

High-performance modules of electronics have started to create higher demands on the manufacturers of assembly techniques to use: from the oldest like Through-Hole Technology (THT) to the more recent Surface Mount Technology (SMT). In particular, among the methods used, surface mount technology has gained favour due to its capacity to sustain the miniaturization process and the trend towards space and efficient module design.

Recent breakthroughs in assembly techniques include reel-to-reel organic electronic printing that will drive the velocity and economy of production processes. Similarly, robust connectivity techniques have been developed for power electronics to make the electronic modules capable of supporting higher power loads imposed by modern electric vehicles and renewable energy systems.

Role of Reliability and Quality in Electronic Module Assembly

The most important concerns in electronic module assembly are reliability and quality. Reliability signifies the consistent ability of the module to execute intended functions over time, especially under mission-critical conditions. Quality refers to meeting the predefined standards that guarantee the module's safe and effective operation. Such high standards are achieved by the application of rigorous testing procedures like Automated Optical Inspection, X-ray inspection, among others, aimed at defect detection, verification of component alignment, and soldering quality.

Reliability and quality of an electronic module are quantitatively measured by metrics such as defects per million parts. These provide data-driven insights into the precision and effectiveness of the assembly process. Hence, manufacturers can ensure high standards for their products.

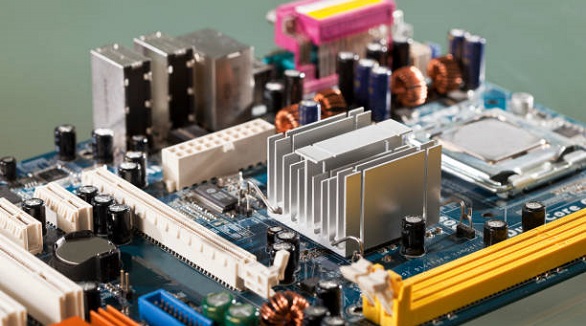

Key Components and Functions

Most electronic modules are composed of a few key components that serve different purposes in the system. Some of the most important components include power inlets, outlets, filters, circuit protection, and voltage selectors, selected according to the needs of the application.

Power Inlet and Outlet

The power inlet is usually designed to follow the IEC 60320 C14 standard and connects electricity to the device. An accompanying outlet allows connection by the module to a power source for easy connectivity into broader electrical systems.

Circuit Protection

Fuses and circuit breakers offer critical protection against electrical faults, which could cause a short circuit to either the equipment or a safety hazard. Fuses are preferable in international products because of their flexibility and ease of replacement.

Filters

At high frequencies and in medical applications, filters are imperative to minimize electromagnetic interference that may affect the stability and safety of the device. A filter uses capacitors and inductors to clean the electricity fed to the device.

Voltage Selector

Voltage selectors extend module's functionalities where devices can operate between voltage standards. This was a bonus for those products exposed to international markets with voltage range differences.

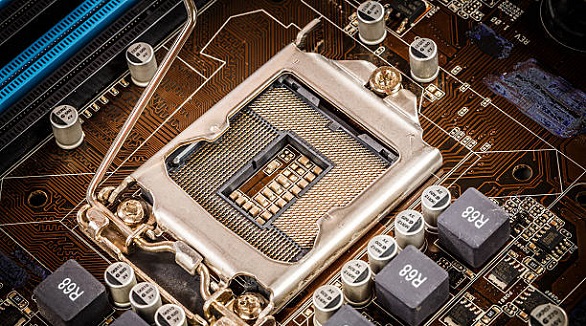

Innovative Techniques in Electronic Module Integration

Improvements on electronic module performance and lifespan have seen manufacturers turn to innovative methods of electronic component assembly that integrate effectively within the module. Innovative assembly techniques use advanced cure and cooling procedures to effect enhanced structural integrity and optimal heat management.

Examples include the curing of a mass between the substrate assembly and the module housing followed by cooling of the circuit carrier to improve adhesive connection. This method helps to increase the resistance against thermal-mechanical stresses of the module, thus increasing its reliability and effectiveness in demanding applications.

Economic Impact and Future Perspectives

The economic implications of electronic modules run deep, with growth witnessed in several industries, from consumer electronics to automotive technologies and renewable energy. Besides, with continuous improvement in semiconductor technology and assembly techniques, electronic modules continue to be more powerful while cost-effective, thus driving innovation.

The challenge in the future, however, will be to sustain such technological advancement with concern for sustainability and efficiency of the electronic module assembly methods. The world is leaning toward smarter and greener technologies, and this requires highly reliable and efficient electronic modules. Emphasis must be on eco-friendly practices and materials that blend with the global trend in sustainability, but their concerns for product performance and improvement in reliability will have to go forward in tandem.

It can be concluded that electronic module assembly is one of the greatest pillars of modern technologies that really stand for the development of new advancements in numerous branches of industries. The innovative technique and robust infrastructure necessary to effect the assembling are, in fact, great motivators of progress towards an ever-improving scenario of contemporary technologies at fast pace. With demands changing continuously, the trade must strike a balance amongst technological innovation, economic viability, and sustainable practices towards electronic module assembly's continued future success.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Carrier PCBs are crucial for data modulation, multiplexing, and network integration, supporting efficient and robust telecom infrastructures globally.

FPGAs offer high flexibility and capacity for complex designs, while CPLDs provide simplicity and cost-effectiveness for smaller applications, crucial in PCBs.

PCB recycling is vital to reduce environmental hazards and recover valuable materials, especially copper. Effective methods include mechanical, chemical, and thermal processes, significantly benefiting sustainability.