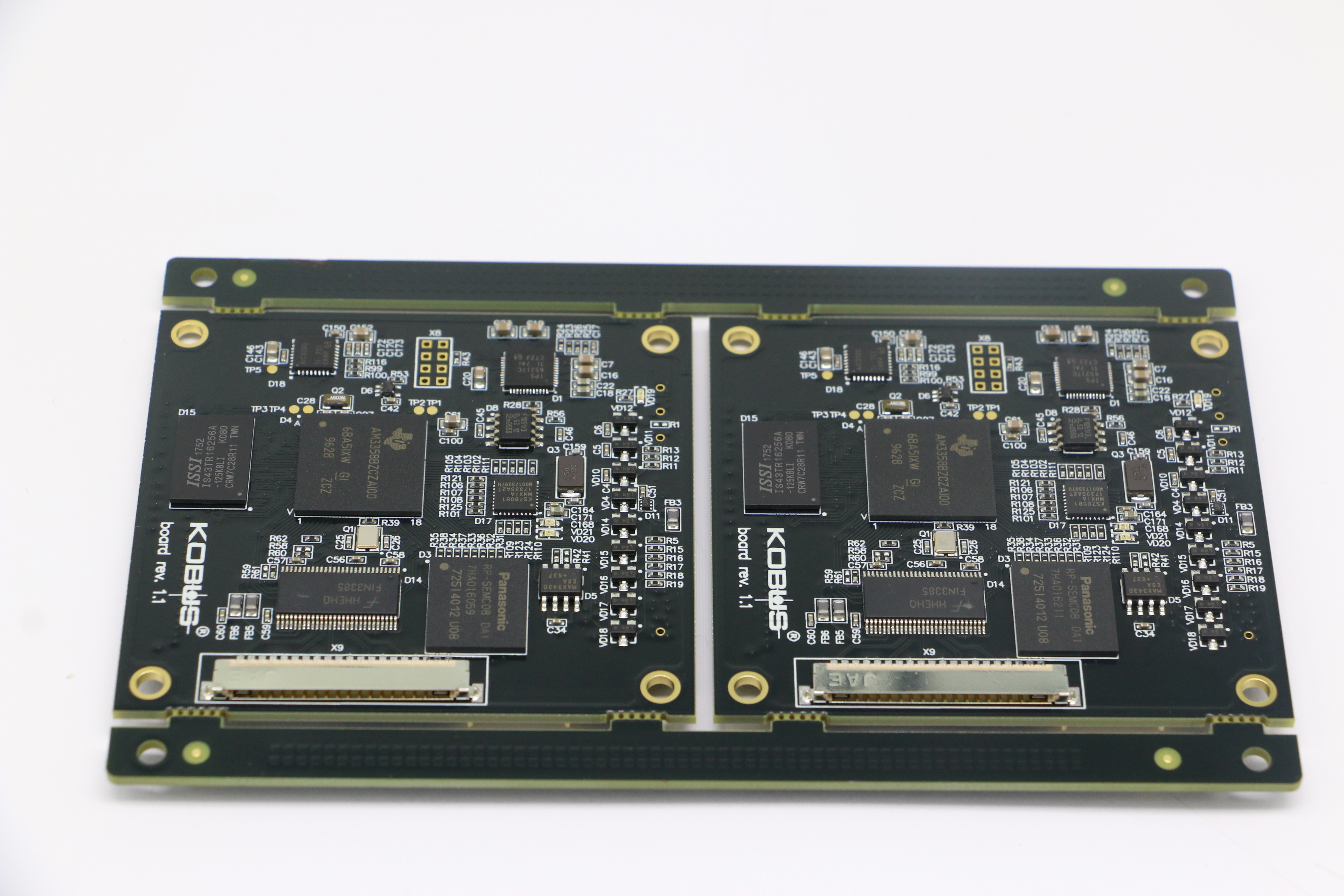

Essential Elements of SMT Assembly

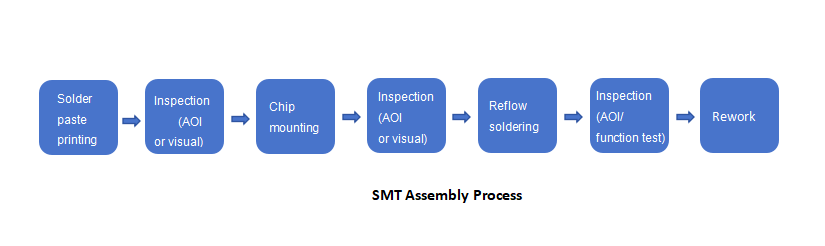

SMT assembly places components directly on PCBs, enhancing miniaturization, performance, and efficiency. Key steps: solder paste printing, chip mounting, reflow soldering, and inspection.

Surface Mount Technology is an assembly technique for printed circuit boards (PCBs) that eliminates the need for holes by directly soldering the components onto the PCB's surface. This post is aimed at discussing some basic elements of SMT assembly so that readers may have a basic concept of SMT.

Brief Introduction to SMT

SMT assembly is the process in which parts or components with either short leads or no leads in the manufacture of electronic devices are attached to associated positions on a circuit board or baseboard. It is reportedly attached permanently to the board using reflow or wave soldering after placement. Different terms are used to refer to these components, such as Surface Mount Devices (SMDs) and Surface Mount Components (SMCs).

Features of SMT

a. Miniaturization:

SMCs/SMDs are light, small, and highly mounting-accurate. Therefore, the weight and volume of PCBs assembled via the SMT method are around one-tenth of those assembled by the THT method. In this case, the reduction in weight and volume allows a decrease of 40% to 60% in volume and 60% to 80% in weight for the final product.

b. High Performance

The defect rate for component soldering in SMT assembly is very low, and it offers good vibration resistance.

c. High Reliability

The high-frequency performance of the electronic products, which are assembled by SMT, is achieved by reducing the EMI and RF interference.

d. High Efficiency

SMT assembly allows easy automation and hence enhances the efficiency of manufacturing to a great extent.

Comparison between SMT and THT

As modern electronics require ever-increasing compactness, THT assembly is gradually being replaced by SMT assembly. When using SMT assembly, components are attached directly to the board's surface as opposed to passing through the board as in the through-hole process.

Generally, an SMT assembly process is divided into four simplified steps: solder paste printing, chip mounting, reflow soldering, and inspection.

Materials in SMT Assembly

In SMT assembly, materials include solder paste, glue, flux, cleaning agents, heat transfer mediums, and more.

Solder Paste

Solder paste serves as both a soldering substance and a bonding agent for SMCs/SMDs on the PCB surface. Sn63/Pb37 and Sn62/Pb36/Ag2 are typical variants with good overall performance. Sn43/Pb43/Bi14 has a lower melting point, making it more desirable. Sn-Pb IMCs are strong and wettable, making them suitable solders.

Flux

Flux removes the oxides and dirt from the metal surface and improves wettability, which helps in smooth soldering. Fluxes may be either acid- or resin-based.

Adhesive

The adhesive is applied to hold SMDs while assembling through the SMT process to prevent the SMDs from getting displaced and detached.

Cleaning Agent

Cleaning agents remove residues left by solder pastes. Such cleaning products should have strong chemical and thermal stability and not degrade during storage. They must also not react with other chemicals or erode things; additionally, they must be non-flammable and low in toxicity. Cleaning must be safe and effective while adhering to time and temperature limits.

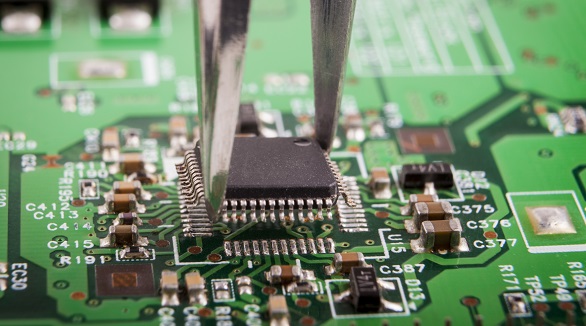

SMC/SMD Mount Technology

SMCS refers to surface mount components, representing the broad meaning of a wide range of chip components. SMDs are used in the process of SMT assembly.

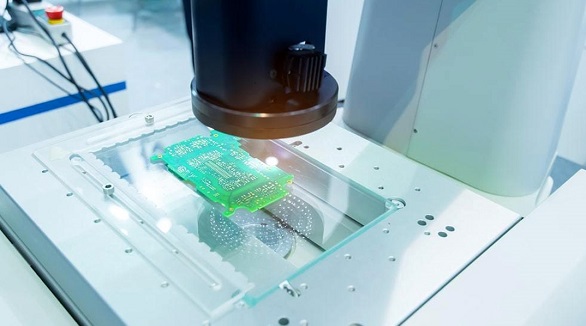

Chip Mounter

Structure

It is a computer-controlled, very precise automated machine. Light, electricity, and mechanics collaborate to achieve SMT assembly.

Mounting Efficiency

Accuracy and speed are the two most important aspects to consider while selecting the chip mounter. Good mounting efficiency denotes assurance of high product quality, increased manufacturing efficiency, and reduced cost.

Factors Affecting Chip Mounter

These include the structure of the x-y axis, movement errors in the x-y axes, the x-y axis inspect variant, and the moving effect of the vacuum nozzle along the z-axis on mounting accuracy.

Visual System

For placements of fine-pitch components, pixel elements and optical magnification settings on the camera must be optimized.

Software System

High-accuracy chip mounters require a second computer control system. The interface of the second computer control system could be DOS, Windows, or UNIX. Software package A complete software system comprises central control software, an auto-programming system, mounter control software, and visual processing software.

Electrostatic Discharge (ESD)

Static Electricity on Electronic Products

Static electricity, caused by positive and negative charges on the surface of an object, will damage electronic products.

ESD Particularity

Static electricity can strike electrical items at random, causing damage that is usually undetectable. Furthermore, it cannot be exposed until the merchandise has left the warehouse.

ESD Protective Measures

- Apply ESD protection in the production area.

- Anti-static wristbands and gloves

- Proper Grounding

- Regular static inspections

- Based on these ideas and practices, SMT assembly can produce a high-quality, efficient, and dependable electronic product.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

With SMT assembly at the forefront of electronics manufacturing, advanced inspection technologies like visual, AOI, ICT, and X-ray are essential due to increasing component complexity. Inspections throughout all stages—incoming, process, and post-reflow—address defects, ensuring quality and reducing rework.

As PCBs and components shrink, AOI (Automated Optical Inspection) replaces visual inspection in SMT assembly, ensuring high-quality solder joint performance through intelligent, optical techniques.

Still, SMT can further feature defects such as solder bridging, cold solder joints, tombstoning, and solder balling. Grasping the very common faults and their solutions is the key toward effective PCB assembly and reducing SMT errors—very much in line with the trend toward PCB miniaturization and higher component density.