First Article Inspection in PCBA

FAI ensures the first PCBA production runs meet design specifications. Automation improves FAI by enhancing efficiency, accuracy, and reducing errors, transforming quality assurance in PCB assembly.

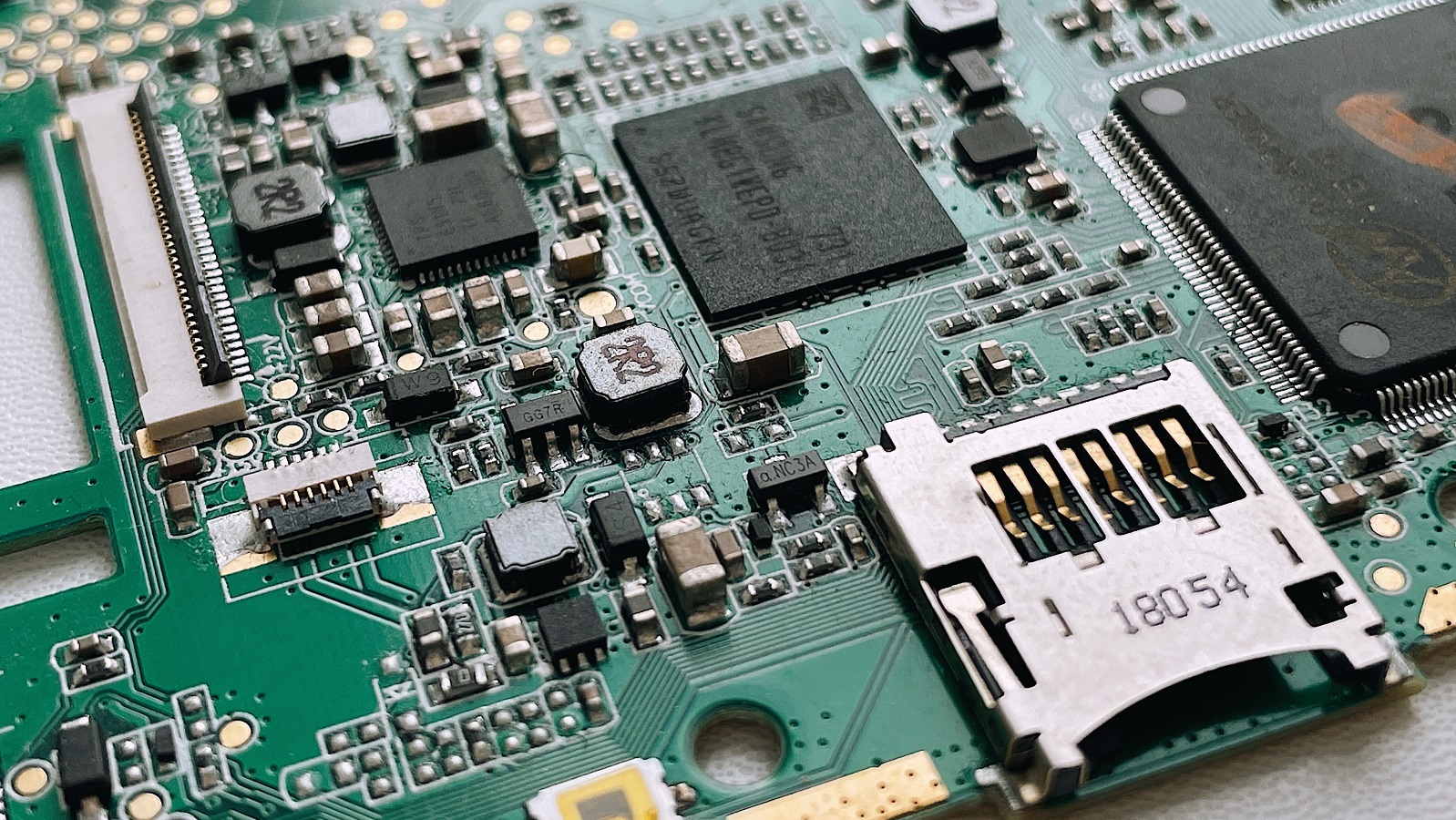

FAI (First Article Inspection) is the fundamental process that ensures the first production run meets the stringent design and quality specifications of the dynamic landscape of Printed Circuit Board Assembly. At PCBX, we care about this touchy process and strive to make it smooth, efficient, and accurate. This article will explain in detail the intricate FAI process and will underline the transformational force of automation.

Importance of FAI in PCBA

FAI means the manufacture of the first article PCB by using SMT lines and their subsequent inspection. The process confirms that the assembly is correctly aligned according to the BOM and that the SMT pick-and-place machine programs are accurate. Traditional ways of performing FAI are literally littered with possibilities for quality issues and inefficiency, considering how changeovers are frequent in the CM environment.

Key Steps in the FAI Process

Preparation and Planning

Check Documentation: Availability and correctness of required documents such as BOM, assembly drawings, coordinates files for pick-and-place programs, and Gerber files used for customizing the solder paste stencil.

Standard Selection: The selection of the relevant inspection standards should be made. Many instances are IPC-A-610.

Component Verification and Process Setup

Cross-Reference Components: Confirm that all components are present to the BOM and are correctly sourced.

SMT Program Verification: Verify the SMT pick-and-place machine programs for accuracy, and the components are placed in the correct feeder locations.

Stencil Customization: Customize SMD stencil per Gerber files.

First Article Assembly and Pre-Reflow Inspection

Screen Printing and Component Placement: Screen printing of the first PCB and component placement.

Minor Pre-Ref low Inspection: Preliminary inspection focused on ICs and polarized parts to make sure of the correct value and orientation of critical components before reflow.

Comprehensive QA Inspection

Detailed Inspection: Against the BOM, the QA department inspects the assembled PCB in detail along with assembly drawings. Each component should be checked whether the pick-and-place machine is correctly set up or not.

Error Tracking: The QA inspector marks each component individually to ensure that nothing is left behind. It becomes a very prolonged process and can delay the commencement of the machines' operation.

Minimizing Risks and Increasing Accuracy through Automation

Human inspections are also prone to many errors due to data inaccuracy, improper documentation, and wrong feeder loading. About this, computerized systems could reduce such risks by a great margin.

Automated First Article Inspection

Data Integration and Initial Setup

Seamless Data Import: FAI system can import BOM, assembly drawings, and CAD data directly.

System Scanning: The loaded and reflowed PCB is scanned, and the CAD data is imported to the screen, showing the details of various parts for an accurate inspection.

Inspection Process

Automated Verification: The system verifies the BOM and Pick-and-place data; any mismatch found will be highlighted automatically.

Visual Aids: All components are represented in an expanded view with data which make for much easier visual inspection.

Efficiency and Precision

High Speed and Accuracy: Inspections via automated systems reduce the time required for inspection by a huge amount and virtually eliminate any errors that can occur with manual systems.

Data Reuse: Once an inspection has taken place, the data will be stored for subsequent use. This allows quality consistency across the runs of the product.

Conclusion

At PCBX, we feel that only an effectively executed First Article Inspection can guarantee quality and reliability in the PCBs. With automated systems in place, the process of FAI is taken to the next level as far as effectiveness and accuracy are concerned. Such evolution not only quickens up the pace of production but also drastically cuts down the chances of error out of the process, hence protecting the interests of our clients by maintaining the high standards of work.

The automated FAI systems are major leaps in PCBA, changing the whole paradigm of how quality and precision are achieved for PCBA. Further commitment to PCBX is manifested by leveraging advances in unequalled electronic manufacturing services, assuring the best possible products for our clients.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

PCB testing ensures quality and reliability by assessing key components like lamination, copper plating, and conductivity. Methods include ICT, FPT, Burn-in, and AOI. Testing reduces bugs, time, cost, and enhances safety.

As PCB lines and components shrink, traditional visual inspection fails; AOI using DRC and CAD methods is crucial for quality SMT assembly, offering intelligent, accurate inspections.

These SMT PCB assembly methods are involved, ensuring that several defects are detected. This includes the use of Automated Optical Inspection, In-Circuit Testing, and Automated X-ray Inspection. The combination of these methods is beneficial in facilitating an optimal inspection process.