Flex & Rigid-Flex PCBs

Flex PCBs fit into devices, saving space, while Rigid-Flex PCBs combine flexible and rigid parts, ideal for varied applications. PCBX offers custom designs, rapid prototyping, and high-quality manufacturing.

Flexible PCB and Rigid-Flex PCB

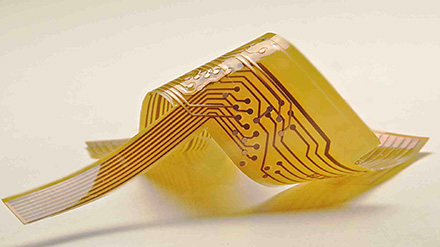

Flexible printed circuit boards, also known as Flexible PCBs or Flex PCBs, get their name from their ability to be constructed in such a manner that they fit into the electronic device or product rather than requiring the device to adjust to the circuit board. These flex boards have distinctively patterned printed circuitry and component layouts, all supported by a flexible base material.

Flexible PCB

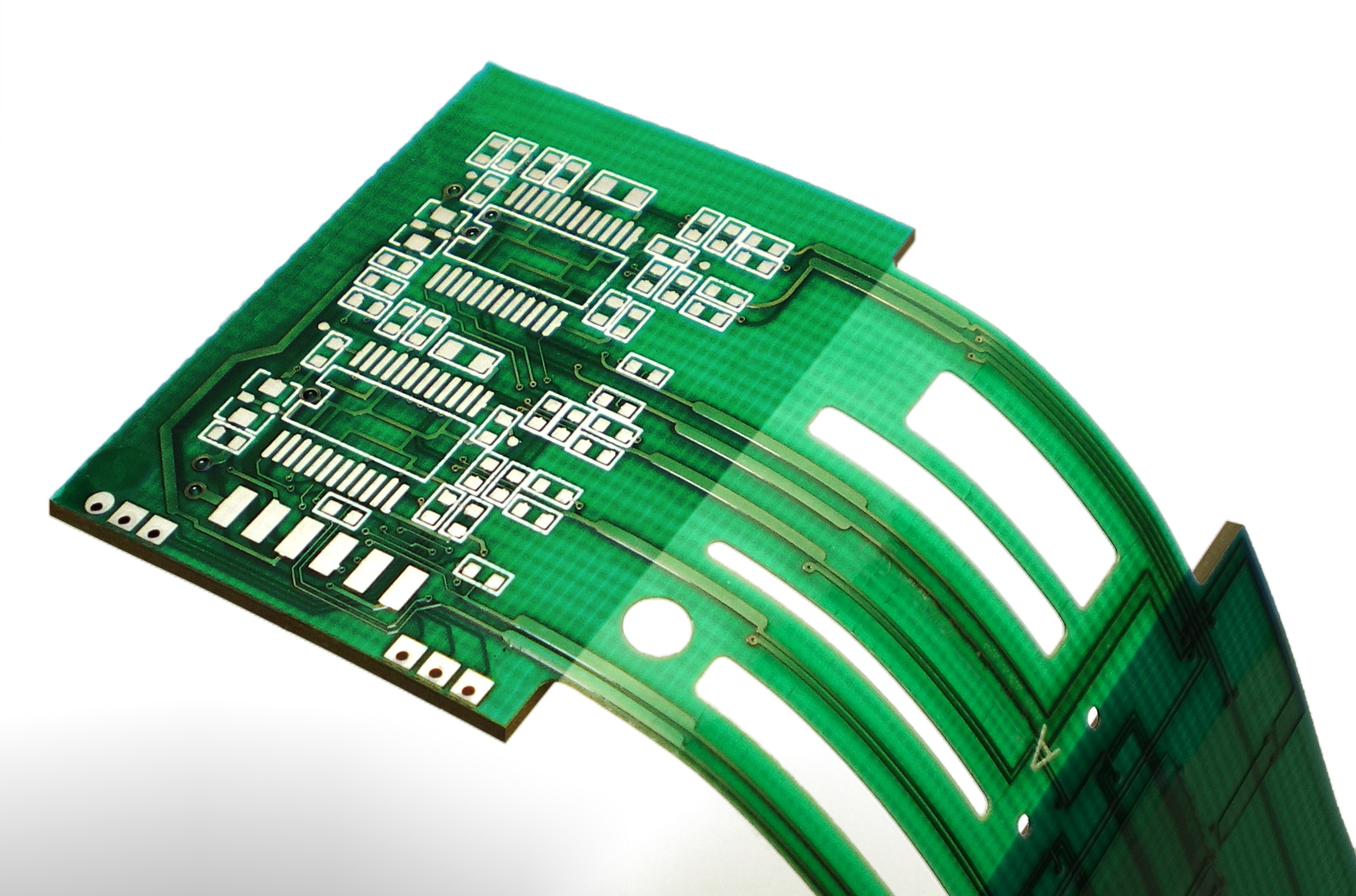

Rigid-flex PCBs are circuit boards that feature both rigid and flexible parts, making them ideal for a variety of applications. A typical rigid-flex PCB circuit includes two or more conductive layers, which can consist of either flexible or rigid insulation material between each layer. The outer layers may have exposed pads or covers. Conductors are present on the rigid layers, while plated through-holes can be found in both the rigid and flexible layers.

Rigid-Flex PCB

Advantages of Flexible PCBs and Rigid-Flex PCBs

Flexible PCBs and Rigid-Flex PCBs, despite their higher initial design and production costs, offer several key advantages that make them invaluable in various applications.

- Flexible PCBs

- Space Efficiency:Requires only about 10% of the space and weight of a conventional circuit board, providing greater installation and packaging flexibility.Reduced size allows for fitting more components into a smaller space, potentially lowering overall system costs.

- Reliability:Fewer interconnects, contact crimps, connectors, and solder joints reduce potential failure points, enhancing overall reliability and reducing maintenance needs.

- Enhanced Capabilities:Compatible with virtually any type of connector or component, including ZIP connectors.Performs extremely well in extreme temperatures and offers superior resistance to radiation and chemicals.

- Cost Savings:Reduced material and packaging demands.Lower parts replacement costs and fewer assembly errors, potentially minimizing the need for repairs.

- Rigid-Flex PCBs

- Robust Performance:Combines rigid and flexible sections, making them suitable for diverse application needs.Performs reliably in harsh environments, particularly those with extreme heat.

- Ease of Testing:Easy to test, enhancing suitability for prototyping.

Common Applications

Both Flexible PCBs and Rigid-Flex PCBs are ideally suited for a wide range of industries, including:

- Military

- Transportation

- Medical

- Consumer Electronics

- Automotive

- Aerospace

- Communications

- Industrial

Flex & Rigid-Flex PCBs Manufacturing Capabilities

PCBX specializes in the manufacture and assembly of flexible and rigid-flex PCBs, which are especially designed for medical devices, telecommunications equipment, and a variety of industrial applications. Our custom PCB manufacturing capabilities enable us to design and produce high-performance Flex and Rigid-Flex PCBs that meet your distinct requirements. Additionally, we collaborate with you to develop custom Flex and Rigid-Flex PCB prototypes, enhancing your chances of a successful project. For a detailed overview of our capabilities, please refer to the following table.

| Feature | Capability | Feature | Capability | |

| Quality Grade | Standard IPC 2 | Quality Grade | Standard IPC 2 | |

| Number of Layers | 1 - 8layers | Number of Layers | 2 - 24layers | |

| Order Quantity | 1pc - 10000+pcs | Order Quantity | 1pc - 10000+pcs | |

| Build Time | 2days - 5weeks | Build Time | 2days - 5weeks | |

| Material | DuPont PI, Domestic Shengyi PI | Material | DuPont (PI25UM), FR4 | |

| Board Size | Min 6*6mm, Max 406*610mm | Board Size | Min 6mm x 6mmMax 457mm x 610mm | |

| Board Thickness | 0.1mm - 0.8mm | Board Thickness | 0.6mm - 5.0mm | |

| Copper Weight (Finished) | 0.5oz - 2.0oz | Copper Weight (Finished) | 0.5oz - 2.0oz | |

| Min Tracing/Spacing | 3mil/3mil | Min Tracing/Spacing | 3mil/3mil | |

| Solder Mask Sides | As per the file | Solder Mask Sides | As per the file | |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow | Solder Mask Color | Green, White, Blue, Black, Red, Yellow | |

| Solder-stop coating---Soldermask oil | Green, White, Blue, Black, Red, Yellow | Silkscreen Sides | As per the file | |

| Solder-stop coating---Coverlay | PI and PET film | Silkscreen Color | White, Black, Yellow | |

| Silkscreen Sides | As per the file | Surface Finish | HASL - Hot air solder levelingLead - free HASL - RoHSENIG - RoHS | |

| Silkscreen Color | White, Black, Yellow | Min Annular Ring | 4mil | |

| Surface Finish | HASL - Hot air solder levelingLead - free HASL - RoHSENIG - RoHSImmersion Tin - RoHSOSP - RoHS | Min Drilling Hole Diameter | 8mil | |

| Min Annular Ring | 4mil | Impedance control | ±10% | |

| Min Drilling Hole Diameter | 8mil | Other Techniques | HDIGold fingersStiffener (only for PI/FR4 substrate) | |

| Min. hole size---Drilling (PTH) | 0.2mil | |||

| Min. hole size---Punching (NPTH) | 0.5mil | |||

| Tolerance of dimension | ±0.05mm | |||

| Other Techniques | Peelable solder maskGold fingersStiffener (only for PI/FR4 substrate) |

How to Get Flex & Rigid-Flex PCBs Fabrication Price?

To get a price quote for the fabrication of Flex and Rigid-Flex PCBs, follow these steps:

- Submit Your Design Files: Send us your Flex and Rigid-Flex PCB design files in Gerber format, which is preferred.

- Include Requirements: Along with your design files, include any specific requirements using our Advanced PCB order system.

- Receive a Quote: We’ll quickly provide a cost estimate for your PCB project.

- Guidance for Order Placement: We will guide you through the order placement process.

Feel free to contact us anytime if you need more information regarding the production of Flex and Rigid-Flex PCBs.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.