Future Trends in Through-Hole Technology: Embracing an Evolving Industry

Through-hole technology remains vital in electronics for its reliability and durability. The article reviews its components, benefits, applications, and evolving trends like miniaturization, SMT integration, and automation.

Through-hole technology has been the backbone of electronic component assembly for a very long period. With its reliability, durability, and ease of use, the technology remains a darling in many industries to date. More importantly, though, the through-hole technology has evolved over time following the evolution of the electronics industry as a whole. The paper will review in detail through-hole components, their types, fabrication processes, and industrial applications. Second, we are going to discuss the future of the through-hole technology-as new developments, innovations, and trends that will affect or bound PCB design and production.

Understanding Through-Hole Components

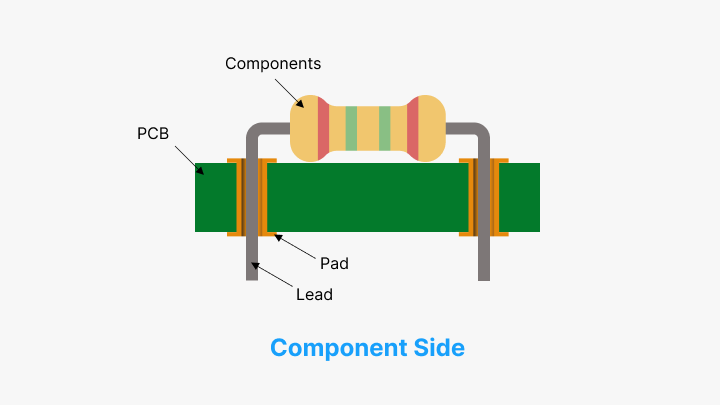

Through-hole components are electronic parts mounted into pre-drilled holes on a printed circuit board and then soldered on the other side to form electrical connections. They provide much-needed mechanical strength and solid electrical contacts, thus making them more ideal for applications that involve harsh environments and/or adverse conditions.

Types of Through-Hole Components

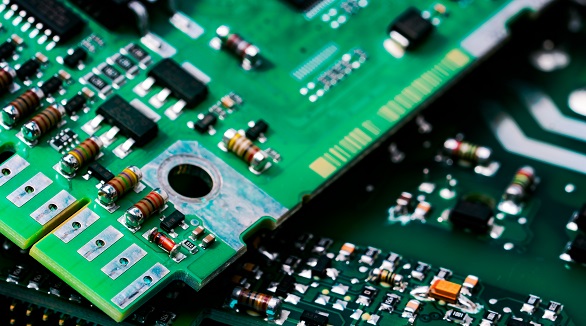

Through-hole technology can be applied in many components, including:

Resistors

Capacitors

Diodes

Transistors

Connectors

These components are provided in a variety of form factors to enable various mounting possibilities and simplify the manufacturing process. Each of these variants enjoys its own construction and functionality that collectively contribute to the total performance of the electronic system.

Advantages of Through-Hole Components

In many respects, through-hole components offer a number of advantages including:

Robustness: Because of their mechanical strength, through-hole components have proven promising in withstanding mechanical stress and vibration under severe environmental conditions.

Reliability: High mechanical integrity of through-hole solder joints maintains long-term stability and less risk of failures in the connection.

Ease of Soldering and Repair: Larger and more accessible leads make soldering and repairs more easy, particularly useful for hobbyists and prototyping.

Application Areas of Through-Hole Technology

Automotive Electronics: The very essentials of vehicle electronics rely on through-hole technology in maintaining reliable connections at the heart of critical systems such as engine control units and safety systems.

Industrial Electronics: Due to the robust construction for high-power circuits, through-hole components find wide applications in automation, robotics, and power electronics, extending their use in industrial situations of control systems.

Medical Electronics: Through-hole technology is also applicable in medical devices when high reliability and safety are required for equipment such as patient monitors, implantable devices, life-support systems, and diagnostic machinery.

Future Trends in Thru-Hole Technology

Miniaturization: While the miniaturization of devices and equipment, in general, poses a challenge, advances in precision drilling and new advanced materials are making it possible to include smaller through-hole components in closer, more efficient configurations on PCBs.

High-Frequency Applications: Growing demand for high-frequency circuits encourages the development of special through-hole component designs with improved high-frequency characteristics that meet the demands of telecommunications for high-speed data transmission.

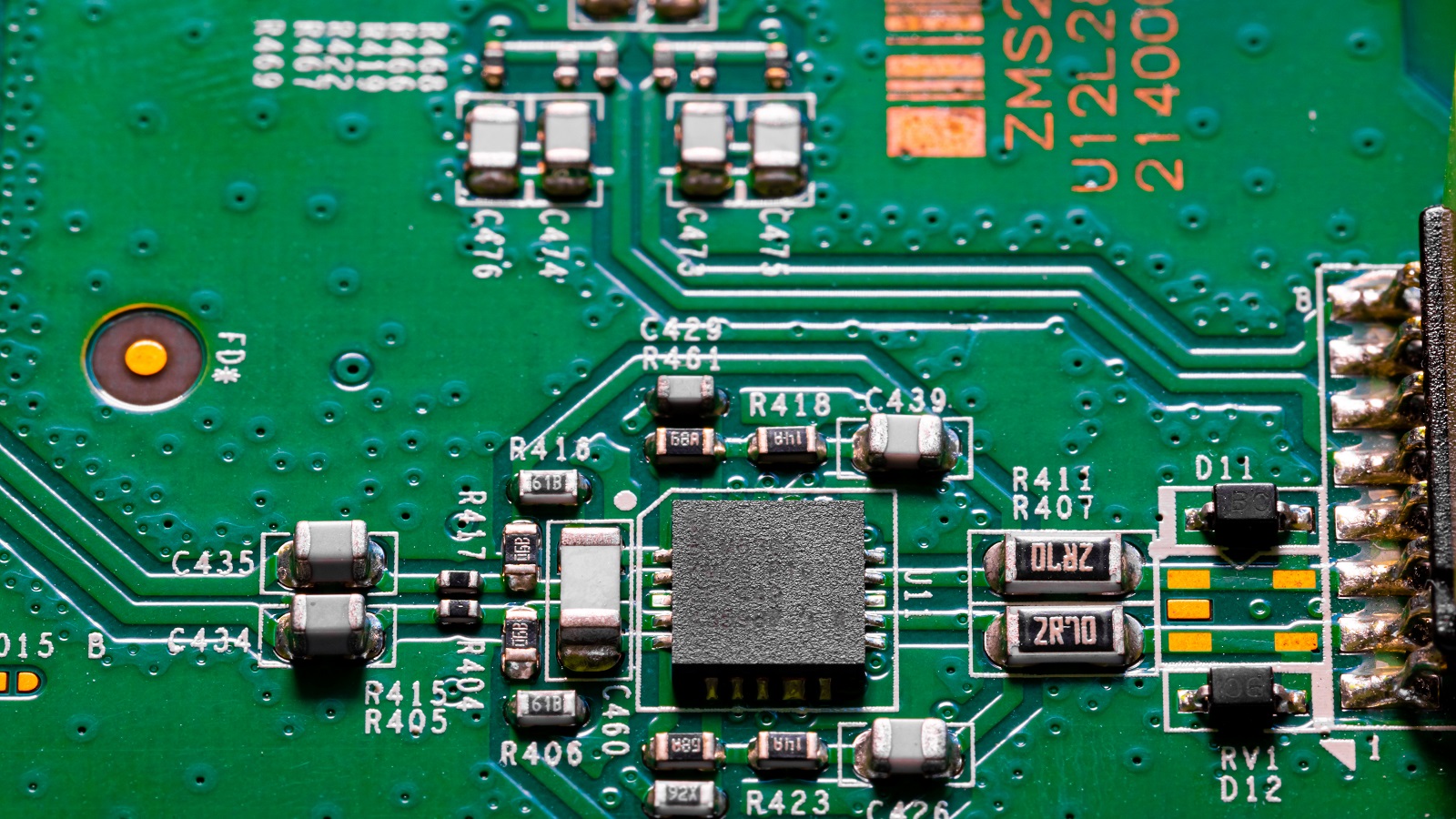

Integration with Surface Mount Technology: Hybrid PCB designs that incorporate through-hole and surface mount components together find wider application. This kind of practice utilizes special advantages of both technologies to best meet performance and assembly efficiency.

Automation and Robotics: Automating through-hole assembly processes using robotic systems ensures quality consistently, hence minimizing or eliminating human error. This machine insertion raises productivity by shortening the assembly times through the precise placement of components into pre-drilled holes.

Selective Soldering: This process allows the soldering of through-hole components with minimal thermal stress to the PCB. Selective soldering machines improve the quality of the solder joints and general reliability by addressing only targeted components.

Environmental Consideration and Sustainability

Lead-Free Alternatives: The transition to lead-free soldering processes and components does comply with environmental regulations by reducing the quantity of hazardous materials used. Therefore, the demand for good reliability with environmentally friendly processes for a lead-free soldering process encompasses considerations of sustainability.

Recycling/Disposal: Correct recycling and disposal of through-hole components reduce electronic waste. Proper recycling in this context should therefore be considered by manufacturers and consumers alike in order to extract value from materials that is still available and to further reduce environmental impact.

Conclusion

In fact, through-hole technology is still so crucial in industry due to its unimaginable reliability, durability, and ease of assembly. Via miniaturization, further development of applications with high frequency, and integration with SMT due to enhanced assembly methods allows through-hole technology to keep up with the evolution of the industry. Environmental considerations continue to spur the development of lead-free alternatives and responsible recycling techniques. At PCBX, not only do we closely follow such novelties, but we also make sure to provide our customers with nothing but the best-quality PCB solutions.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Through-Hole Technology (THT) mounts electronic components by inserting their leads through pre-drilled PCB holes and soldering them. While durable and ideal for harsh conditions, THT is less space-efficient than SMT.

Through-hole assembly is a key PCB manufacturing technique offering reliability and mechanical strength. This article details design elements, requirements, and standards, including thermal pads, IPC performance levels, component types, solder joint quality, hole sizes, and annular ring dimensions, ensuring robust and manufacturable PCBs for various applications.

Printed Circuit Board Assembly (PCBA) employs Through-Hole Technology (THT) and Surface Mount Technology (SMT). THT offers robust mechanical bonds, ideal for high-stress applications, whereas SMT supports efficient, high-density assemblies. Each method has unique advantages and limitations, impacting cost, manufacturing efficiency, and component compatibility. Understanding these differences is key for optimal PCB design.