How Much Does PCB Assembly Cost?

Key factors influencing PCB assembly cost include labor, turnaround time, quantity, technology, packaging, board size, material choice, layers, hole size, and finish. Manage costs by optimizing design, ordering in bulk, selecting suitable materials, and negotiating lead times.

If you are in the process of ordering printed circuit boards, knowing the associated costs for appropriate budgeting and planning of the project is very important. Several factors go into determining the cost of PCB assembly, which includes design, labor, quantity, turn time, and technological difficulty. In this article, these elements will be covered to give a better understanding of PCB assembly costs.

Key Factors Influencing PCB Assembly Cost

1. Labor Cost

Labor is one of the biggest factors that affects the cost of assembly, and it varies with the geographical location of a facility.

Geographical Impact: Clearly, lower labor cost countries can provide cost savings. However, these benefits might be at the expense of increased shipping costs and possible communication delays. Sometimes, logistics and quality control issues might offset any perceived cost savings related to overseas manufacturing.

Skilled Workforce: High-quality PCB assembly needs the work of experienced technicians as much as it needs automatic machines. A skilled workforce often leads to higher reliability and accuracy, which offsets the rising labor cost.

2. Turnaround Time

The time consumed in the manufacturing and delivery of the PCBs is called the turnaround time, which plays a very crucial role in deciding the cost.

Expedited Production: The need for quick turn-around will add premium, possibly increasing the base cost by one-third (33%).

Shipping Costs: Faster production time usually means expedited shipping which adds further to the overall cost.

3. Quantity

Whenever you order larger quantities of PCBs, the cost per unit is usually lower due to economies of scale.

Economies of Scale: Higher order quantities spread the startup costs and programming efforts over more units, lowering the per-unit cost.

Bulk Discounts: Many manufacturers will offer better pricing for bulk orders, in that case—this is sometimes what makes it cheaper to order in higher volumes.

4. Technology

The same general technologies involved in PCB assembly will affect the cost greatly.

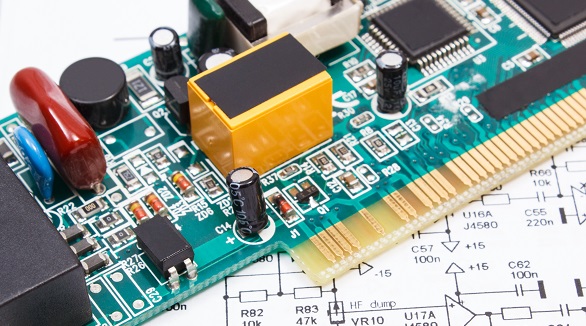

Through-Hole Technology: This is the oldest of the processes, where component leads are placed into pre-drilled holes. Since THT requires much more work than the newer methods, it is costlier.

Surface Mount Technology: Components are attached or mounted directly onto the surface of the board. While generally having a lower setup cost, there are some instances where THT might be needed, increasing the cost.

5. Parts Packaging

The complexity and sensitivity of the components may raise the cost of parts packaging.

Sensitive Packaging: Increasing content of BGAs in many modules, together with the attendant processes for packaging and the use of supplementary inspections like the X-ray to identify defects, add to labor and thereby raise the overall cost.

6. Size and Complexity of PCB

The size and complexity of the PCB design play a vital role in costs.

Dimension and Utilization: It helps to maintain costs investment if the board dimensions and panel space are used efficiently. Larger board as compared to the small ones will definitely require more material and labor investment.

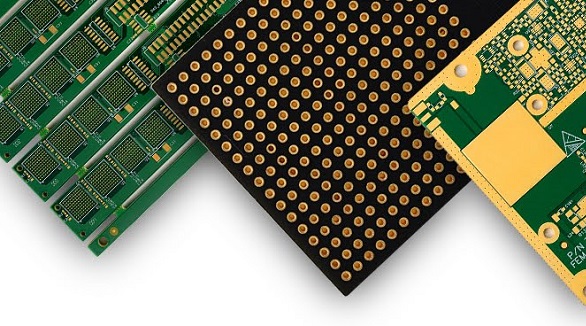

Layer Count: Since multi-layer PCBs go through more steps of production and are complicated, it means they are more costly than simpler double-layer boards made of PCBs. More extended multi-layer circuits are more expensive than the shorter and simpler ones.

7. Material Selection

Material choice becomes one of the critical costs within PCB assembly.

Substrate Material: Generic materials like FR-4 are cheap. However, special materials – like ceramics or flexible materials – are expensive.

Copper Thickness: Thicker copper layers carry more currents and dissipate more heat but require more material and process in construction.

8. Number of Layers

The complexity of the PCB, particularly the number of layers used, determines costs.

Simple vs. Multi-Layer Boards: In general, two-layer boards are easier and less expensive to implement than boards with more layers; these multi-layer boards have complicated procedures and subsequently more chances of defective boards.

9. Hole Size

The hole size and the complexity of the drill include their tooling cost in the manufacturing.

Drill Needs: More number of holes or smaller sized holes require advance tooling and time, and therefore naturally increase cost.

10. PCB Finish

The finish of a PCB is another of the design attributes that affect the cost and performance of the same.

Surface Treatments: Low-cost finishes like HASL are fair in performance, while high-grade finishes like ENIG offer superior solderability and a longer life but are costly.

Practical Cost Estimates

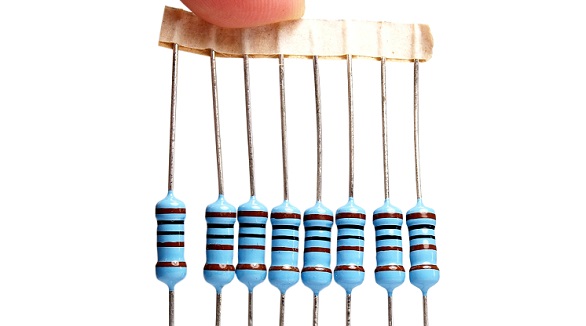

PCB assembly generally varies in the cost from $0.02 to $0.05 per square inch, mostly based on factors associated with labor, material, and overhead expenses. Besides, these costs include the electronic purchases like resistors, capacitors, microchips, connectors and purchasing the electronic components. The quality of these components and how complex the PCB design is will further affect the final cost.

To manage these expenses effectively:

Optimize Design for Manufacturability (DFM): It is essential to simplify the design without compromising performance in order to keep costs in check.

Order in Bulk: The more ordered, the lower the per-unit costs.

Select Appropriate Materials: Balancing cost and performance needs helps in keeping material expenses in line.

Negotiate Reasonable Lead Times: Use standard production schedules to eliminate premiums associated with expedited services.

In this regard, the costs for PCB assembly include different types of factors concerning labor, quantity, technology, parts packaging, board size, material choice, layer counts, hole sizes, and surface finishes. You now know how to estimate and control your PCB assembly costs—not only is your project cost kept on track, but there is room for all performance specifications.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Turnkey PCB assembly means the provider handles everything from component procurement to manufacturing and assembly. PCBX, serving 80+ countries, offers reliable, cost-saving, one-stop solutions with faster lead times and consistent quality.

One is a bare circuitry board, and another has all the components and is functional: PCB stands for Printed Circuit Board, and PCBA stands for Printed Circuit Board Assembly. PCB acts like a base, and components are assembled on it at a later stage through various methods in PCBA, such as SMT and Thru-Hole Technology.

Customers prefer one-stop PCBA service not only because of price transparency; it can save time and reduce labor costs with efficiency and professionalism in procurement and production.