How to Discharge a Capacitor

Capacitors must be safely discharged to prevent shock and damage. Use insulated tools, check voltage, and follow protocols to ensure safety during maintenance.

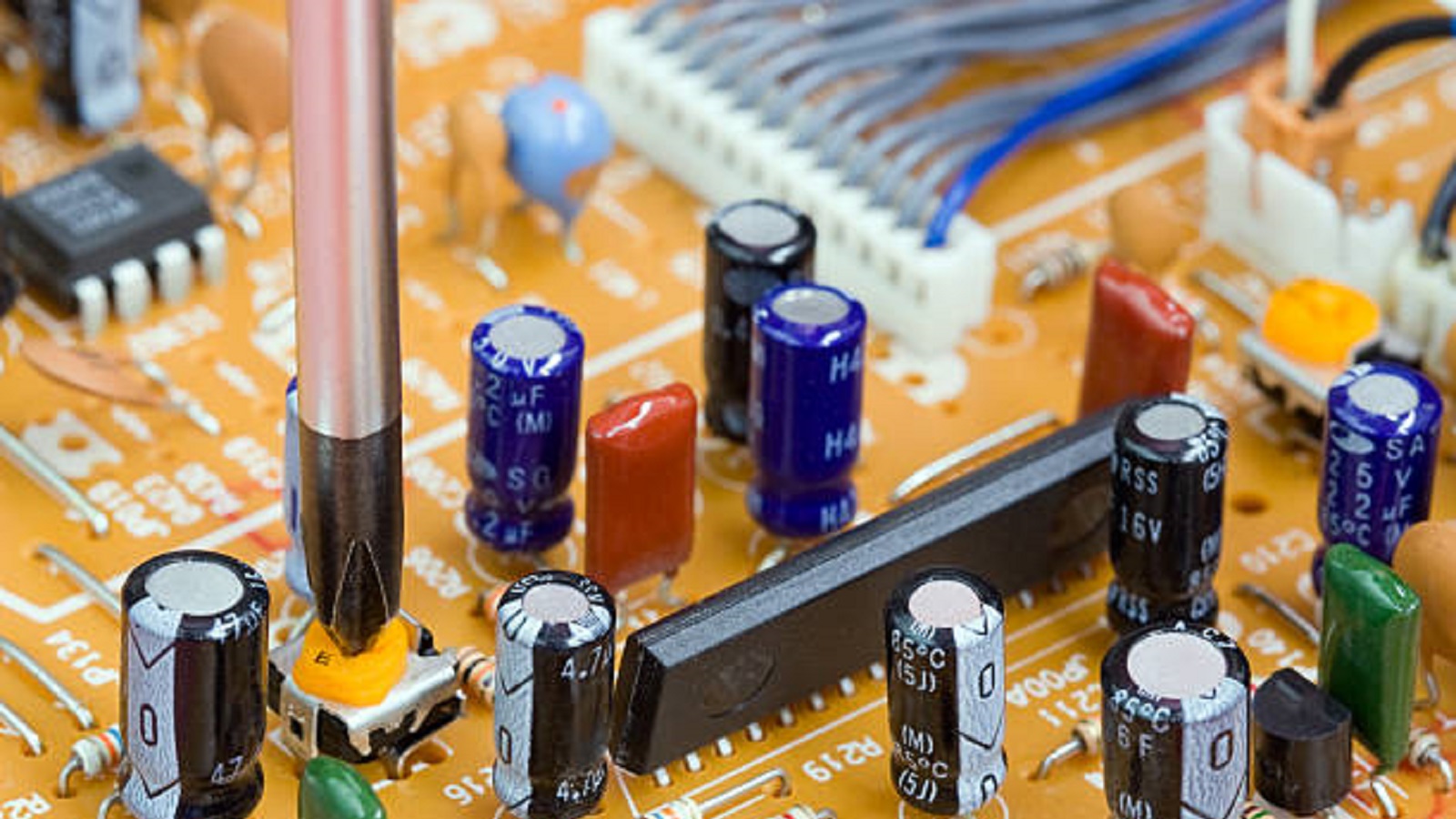

Capacitors are indispensable in electronic circuits: accumulating and releasing energy when needed. While this makes them very useful in powering diversified machinery, one must ensure, prior to any maintenance or handling, that the capacitors are discharged safely. Proper discharge helps prevent electrical shock and equipment damage. This article goes into detail on the safety discharging of a capacitor, discussing risks, methods, and safety.

Capacitors can store electrical energy between two conductive plates separated by some insulating material and are capable of holding a charge long after being disconnected from a power source. This secreted charge presents hazards, including electric shock and possible damage to technicians and equipment during repairs or maintenance.

Why and how a capacitor should be discharged safely is what has to be taken into consideration. It saves one from accidents while maintaining a controlled environment for electronic work. The voltage and stored energy within a capacitor are related to the capacitance applied and the voltage previously applied, so discharge techniques are specific according to the action involved.

Why Discharge a Capacitor?

It is because a capacitor discharging altogether removes the stored energy and the hazards associated with retained charge in capacitors. It is very important for:

Avoid Electrical Shocks: A small quantity of residual charge can deliver a significant shock, possibly lethal.

Prevent Equipment Damage: Energized capacitors can discharge through sensitive devices, causing them to be destroyed.

Provide Safety for Repairs: Generally, technicians are safe working on deenergized systems.

Essential Safety Precautions

Before discharging a capacitor, prioritize safety by:

Verification of Power Disconnection: Make sure the device is totally unplugged to avoid the unexpected flow in power.

Insulated Tools: Use non-conductive, insulated tools only to avoid any case of accidental circuit completion.

Methods to Discharge a Capacitor

For safely discharging a capacitor, a number of techniques are in use. The procedure adopted varies greatly with respect to voltage and environment. These methods include:

Multimeter

While there is no way to use a multimeter as a means to discharge a capacitor, it does offer a method for measuring the charge with the intent of ascertaining what type of discharge would suit best. Instructions are as follows:

Turn Off and Unplug: First things first, ensure that the power source is unplugged.

Measure Voltage: Next, one will use the voltmeter setting to obtain an idea about the amount of charge stored within.

Proceed with Discharge Technique: From here, one can proceed with whatever discharge technique is most appropriate upon completion of the voltage reading.

Metal Object (Screwdriver)

This is the most common method which immediately dissipates charge when doing DIYs. However, be careful not to spark or short circuit anything:

Safety Voltage: Only use below 50V.

Insulated Screwdriver: Touch the insulated handle to avoid any sort of shocks.

Touch Both Terminals: Touch both capacitor terminals together in such a way that voltage discharges safely.

Bleeder Resistor

Controlled discharge - normally in high-voltage capacitors.

Choosing a Resistor: Select a resistor proportional to the voltage, allowing gradual discharging.

Connect Across Terminals: Connect one end of each resistor to each terminal for a path to discharge.

Measure Voltage Again: Use a multimeter to check if it is completely discharged.

Light Bulb

A very practical technique which also gives a visual confirmation of discharge:

Switch Off Supply: Ensure there is no connection to a power supply.

Connect in Series: The light bulb is connected across the capacitor terminals.

Watch it Dim: The light will dim as the charge bleeds off, and then it's done.

Special Discharge Tool

Such tools are made to ensure that discharge occurs safely and in a controlled manner:

Choose the Right Tool Type: It needs to be compatible with the type of capacitor and voltage.

Use the Tool According to Its Instructions: Be very careful to follow instructions to avoid misusing it.

Cross-Check with Multimeter: Ensure that no charge remains after being discharged.

Safety during Execution

The follow techniques would ensure safety to the fullest if executed with due care:

Verification: Check again for capacitor charge after discharge to ensure safety.

Environment Control: Work on insulated surfaces, away from conductive materials.

Emergency Preparedness: Have a response plan for electrical accidents.

Safe discharging of capacitors is an important practice to be followed by one and all-amateurs to professionals-who are involved in electronic work. This guide highlights the ability to comprehend functions of a capacitor, embedding good practices for comprehensive discharging, and insisting on observing safety.

With the proper tools at hand, such as multimeters, screwdrivers, bleeder resistors, light bulbs, or discharge tools, one can make certain that safety is guaranteed for both persons and the integrity and longevity of electronic devices and components. Always follow established protocols and safety procedures in the ever-evolving world of electronics, so your environment is always safe and innovative.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Functional testing verifies PCB functionality in simulated environments, enhancing quality and reliability, detecting faults, ensuring performance, and cost efficiency.

PCB recycling is vital to reduce environmental hazards and recover valuable materials, especially copper. Effective methods include mechanical, chemical, and thermal processes, significantly benefiting sustainability.

Capacitors are crucial in circuits for storing energy. Testing methods include in-circuit and out-of-circuit using digital multimeters, ESR, and LCR meters. Proper testing ensures reliability and prevents malfunctions.