How to Find the Serial Number for PCB Boards

Serial numbers on PCBs are crucial for traceability, quality control, warranty support, and inventory management, ensuring compatibility and efficient device management.

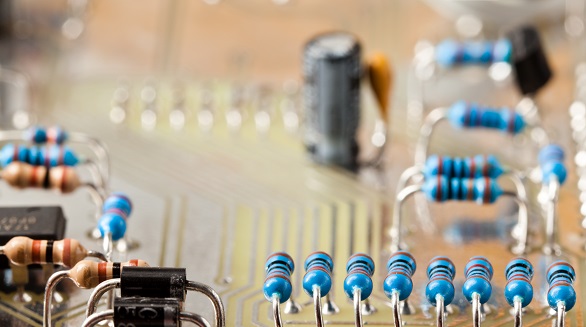

Printed Circuit Boards (PCBs) are found everywhere in today's electronics revolution and are the infrastructural foundation of innumerable devices. At PCBX, we understand the importance of each PCB and the serial number's importance in ensuring reliable and efficient management of devices. For replacement, repair, and stock control, serial numbers ensure traceability. This full guide will walk you through how to locate serial numbers on PCBs with some insight into why they are crucial.

Serial numbers in PCBs are key identifiers that trace and contain history of the board. Because manufacturers modify components or designs periodically, serial numbers allow correct tracking, ensuring compatibility and functionality when repairing or upgrading. A serial number can encapsulate the board's manufacturing history, component information, and even the technology used in production.

What Are Serial Numbers and Why Are They Important?

Serial numbers serve a number of vital roles:

Traceability: They enable tracing of the manufacturing history, i.e., the batch and individual manufacturing stages through which a board has traveled.

Quality Control: Serial numbers facilitate easier performance of quality control and quality assurance activities, as they help identify and isolate faulty batches or components.

Warranty and Service Management: They facilitate easier warranty claims and repairs by enabling unique identification of each board, thus making it easy for manufacturers, service shops, and customers to communicate.

Inventory Management: With a serial number log, companies can better manage inventory, track usage patterns, and predict future needs.

Finding the Serial Number on a PCB

Finding the serial number on a PCB can seem to be a task of overwhelming complexity, but with the following steps, it can become easier:

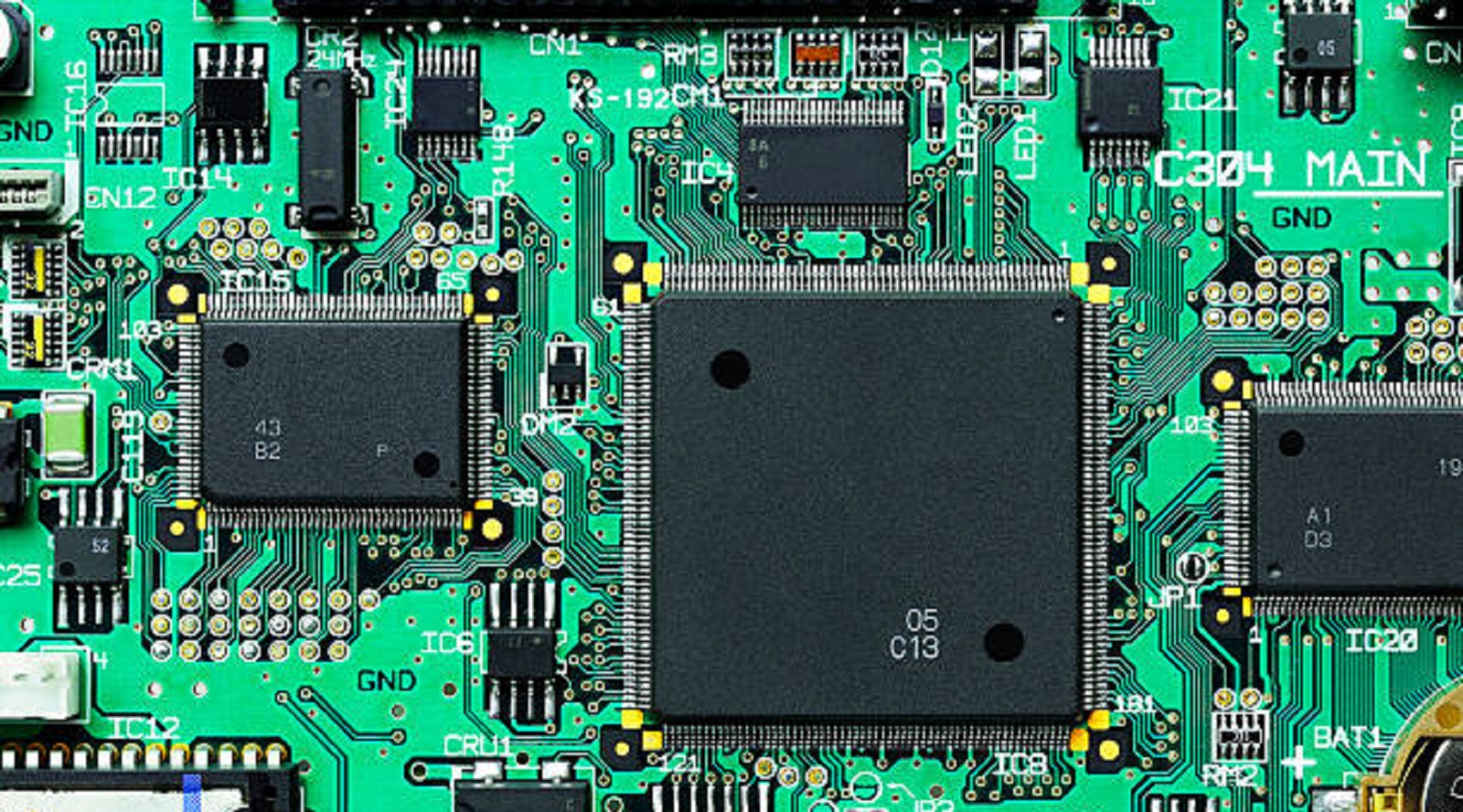

Visual Identification of Part Numbers

Begin by visually checking the board for part numbers. There are typically two kinds:

Individual Part Number: This number refers to the bare PCB.

Circuit Card Assembly (CCA) Number: This figure represents the board with all its components.

Close by may be a serial number, usually stamped, printed, or hand-written. These are usually short alphanumeric or hexadecimal strings and could be preceded by "SN" or "S/N."

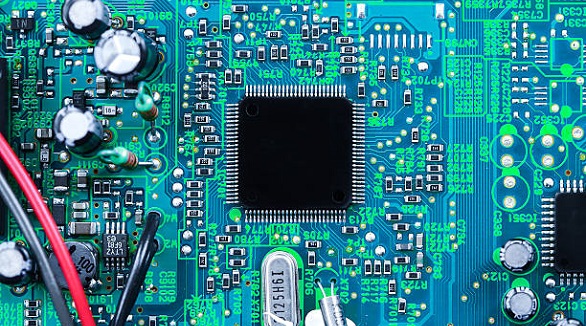

Detailed Steps for Visual Inspection

Front and Back Surface Check: Check both sides of the PCB. The serial numbers could be printed on both sides, so one should not overlook any information.

Silk Screen Layer: The serial number and most other component designators are typically printed on the silk screen layer in most boards.

Edges of PCB: In designs in which the serial number can obstruct the main function, manufacturers will place them at the edges.

How to Deal With

Magnification Tools: The text for these numbers could be extremely minute. Use a magnifying glass or a digital microscope to properly read.

Good Lighting: Ensure that you have adequate lighting so as not to cause mistakes by shadows or dim lighting.

Etched Part Numbers

These are part numbers etched onto the board itself, usually on ground planes or large wiring traces. These are usually metallic areas covered in solder. In such areas, you might also notice the manufacturer's logo or a patent number. Serial numbers in such areas are not uncommon, and sometimes they have small stickers attached to them which might also have barcodes for easy scanning.

How to Check for Etched Numbers:

Inspect the Metal Surfaces: Inspect any visible metal surfaces since serial numbers may be engraved on such conductive surfaces.

Look for Adjacent Indicators: Manufacturers usually place indicators like logos or patent numbers in the vicinity, which prove helpful in identifying the serial number.

Serial Number Retrieval through Computer Systems

Advanced PCBs that are part of complex systems can contain serial number data within their onboard memory systems. To read this data typically requires gaining access to onboard firmware or utility communications programs.

Serial Data Communication Software: Certain programs like WinViews can be used to execute some commands to receive the serial number and associated details. A good example is the case where gaining access to a command line from within the application allows a user to extract unit serial numbers, modification statuses, etc.

Professional Repair Shops: Professional shops are likely to be equipped with the tools and software required to execute these procedures and hence professional support becomes essential in some cases.

Practical Safety Precautions and Advice

When you're in the process of searching for the serial number on a PCB, adhering to some best practices increases your chances while ensuring your safety and the board's:

Electro-static Discharge (ESD) Precautions: At all times, adhere to rigorous ESD precautions when handling PCBs. Electrostatic discharge could cause irreparable harm to delicate components on the board. Use antistatic wristbands and work on antistatic mats wherever available.

Serial Number Documentation: Upon identification, document the serial number through good pictures. These records are important for future reference or if physical numbers expire over time.

Board Handling: Handle the board with reduced handling, grasping it by the edges to prevent risking introduction of dust, oils, or static charges.

Accuracy is paramount in the electronics industry, and we at PCBX understand how crucial it is to be able to manage your PCBs. Locating a serial number is more than just a step; it's an entrance to knowing about your board's history, ensuring compatibility, and system integrity. Whether for inventory management, repairs, or service claims, knowing how to efficiently trace a PCB’s origins and components enhances your capabilities as a technician, engineer, or hobbyist. By following this guide, you’re not just discovering a number – you’re acknowledging the intricate history and future possibilities of every board in your possession. Trust PCBX for innovation and unparalleled expertise in PCB management and solutions.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Ordering PCBs involves defining needs, detailed documentation, sourcing strategy, and post-order management, while PCBX ensures top-quality PCB production.

Effective PCB design ensures reliable electronics by optimizing component placement, connections, and testing, enhancing performance and longevity.

PCBs are crucial in electronics, providing a platform for component interconnection. Mastering component identification ensures effective design, troubleshooting, and maintenance, vital for device reliability and performance.