How to Get BGA Perfectly Soldered on PCBs in SMT Assembly

Ensuring BGA soldering quality involves defect prevention, pre-soldering measures, and precise control during SMT assembly and reflow soldering.

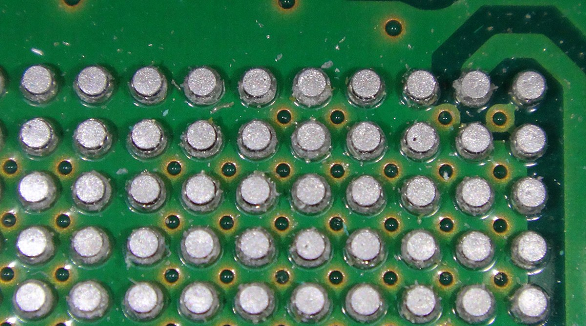

Because BGA (Ball Grid Array) solder balls are hidden under the body, it’s not easy to inspect their performance. Up to now, Automated X-ray Inspection has been applied to help expose the defects of BGA solder balls including void, displacement, bridging, cold solder, etc. When flaws are discovered, rework must be implemented. However, rework is always expensive, which is not necessary for OEMs. As a result, the primary goal is to ensure the quality of BGA solder balls by efficiently preventing the formation of solder flaws. So, this article will discuss the key elements to be captured in the process of SMT assembly.

It’s necessary to indicate that all the tips are summarized based on manufacturing experience in PCBX’s workshop. PCBX has been serving globe electronics for 20 years. Up to now, we’ve served more than 10,000 customers from over 80 countries and regions around the world with HIGH-RELIABILITY and LOW-COST bare PCBs and assembled PCBs that have been widely applied in numerous fields covering medical care, industrial control, transportation, military, aerospace, IoT, etc.

Mechanism of BGA Soldering

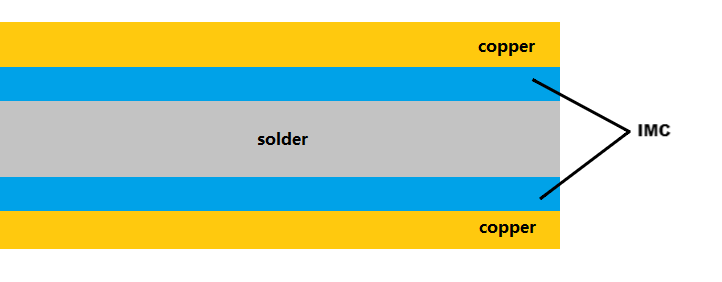

As the temperature rises over the melting point of the solder, the oxide layer generated on the pad's copper surface is cleansed as a result of flux activation. When properly applied, the copper surface and metal particles in the solder interact with one another. The cleaned pad surface is wetted with molten solder, resulting in a phenomenon known as chemical diffusion. This direct technique creates an IMC on the solder and pad surfaces.

How to Achieve Perfect BGA Soldering in the SMT Assembly Process

SMT assembly generally includes the following processes:

- Printing solder paste;

- SPI (Solder Paste Inspection) - Optional;

- Chip mounting;

- Reflow Soldering;

- AOI (Automated Optical Inspection);

- AXI (Automated X-ray Inspection) Optional;

- Rework Optional.

- Major measures for optimizing BGA soldering during the SMT process will be implemented both before and during the process. The measures will be discussed in two parts: pre-soldering and during soldering.

Pre-Soldering

PCB Board Preparation

Surface Finish Selection: Select a surface finish compatible with project or product requirements. There are several surface finish possibilities that require introduction and comparison. Lead-free surface coatings such as lead-free HASL, ENIG, or OSP may be used on ROHS-compliant goods.

Proper Storage and Handling: The board must be properly stored and handled. They should be placed in an electrostatic discharge protection bag with a moisture barrier and a moisture-sensitive indicator card. For humidity control inspection, an indicator card monitors the humidity within a bag in an easy and cost-effective manner. The card's color change reveals the relative humidity inside the bag as well as the efficacy of the desiccants. If the humidity within the bag equals or surpasses the indicator value, the circle turns pink.

Baking and cleaning: Baking the PCBs can help prevent moisture defects during soldering. Maintain a temperature of 110±10℃ for 2 hours. Second, the handling process may result in dust being deposited on the boards, which are thoroughly cleaned prior to assembly. An ultrasonic cleaner is utilized at PCBX to ensure that the constructed PCBs are extremely clean, significantly boosting the board's reliability.

BGA Preparation

BDAs are moisture-sensitive components. They require storage at constant temperature and dry conditions. Many strict procedures have to be followed in the whole process in order not to damage the condition of the components by operating personnel. Normally, the BGA component should be stored in a moisture-proof cabinet at 20-25 with a humidity of 10%. It is advisable to use nitrogen.

For the BGA components, some baking is required before soldering. The temperature should not reach 125 ℃ to avoid altering the metallographic structure of the components. Later, during re-flow soldering, higher temperatures may cause a disjunction between the solder balls and the component package, leading to lower SMT soldering quality. With an excessively low consortium temperature, moisture removal sometimes may prove impossible, which usually poses a problem. Thus, it is advised that the components be baked before SMT assembly, not only to eliminate their internal moisture but also to enhance their heat resistance. The BGA components should also be cooled for an average of half an hour after baking and before they enter the SMT assembly line.

During Soldering

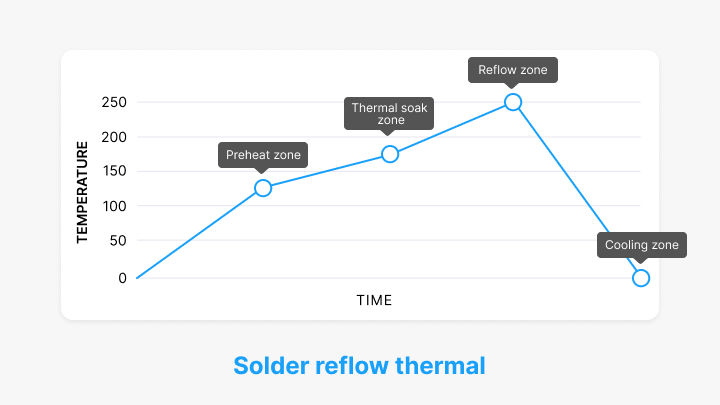

The reflow soldering procedure is hard to control; thus, the optimal reflow temperature profile of the high performance of BGA components must be attained.

Preheating Zone

During the preheating phase, the gradual temperature increase allows the activation of the flux. The temperature hike should be uniform to prevent deformation of the PCB as a result of rapid heating. The recommended elevation of temperature should be below 3 ℃/s, with 2 ℃/s being the best value, for some time, say 60-90 seconds.

Thermal Soak Zone

The flux starts to volatilize out in the thermal soak zone. The temperature should be kept between 150℃ and 180℃ for 60 to 120 seconds to make sure the flux is completely volatilized. The rate of temperature rise should generally be kept at 0.3 ~ 0.5℃/s.

Reflow Zone

The reflow zone is where the temperature goes up and crosses the melting point, and the solder paste liquefies. The temperature has to be more than 183℃ for 60 to 90 seconds. As this will affect the quality of the soldering, both too-short and too long periods must be avoided. Hence, the time in the temperature range 220±10℃ has to be exactly managed to stay within 10 to 20 seconds.

Cooling Zone

The solder paste begins to harden as it enters the cooling zone, securing components to the PCB. The temperature reduction must be such that it does not achieve extremely fast rates. Poor cooling can cause rapid temperature reduction on the PCB, reducing the quality of BGA soldering significantly.

To ensure quality, it is possible to meet these standards by making sure that BGA components are soldered onto PCBs strictly. PCBX is a one-stop shop for PCB assembly, capable of handling BGA pitches as small as 0.35mm. Furthermore, the items go through rigorous inspections, such as AOI and AXI, which affects their performance and dependability.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Compared to THT, SMT offers better miniaturization and weight reduction in any electronic application. With the use of BGA packages, high-assembly density, reliability, and improved performance are achieved; on the other hand, this requires a rework and inspection that is not really common. PCBX specializes in the area of advanced SMT and BGA assembly to help drive modern requirements of compact electronic devices.

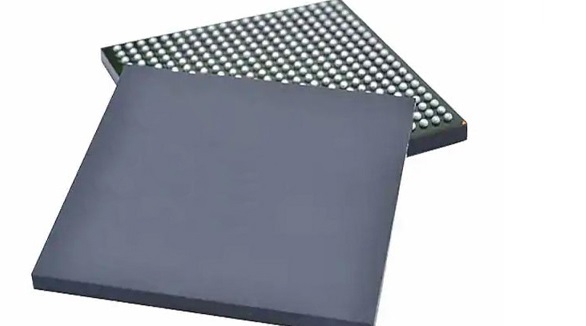

Ball Grid Array (BGA) components, such as PBGA, CBGA, CCGA, TBGA, and CSP, provide high I/O density, improved reliability, and high-quality electrical and thermal performance. Quality assembly and functionality are assured since advanced soldering and inspection methods are required, like AXI and AOI. Proper storage and handling shall guarantee the performance of the devices.

In the late 1980s, when electronics began to shrink, BGA packaging was developed to integrate more connections within a given area. Today, BGA is widely used with high-connection chips—processors being a good example. BGA uses solder balls at the bottom of the chip to connect it to the circuit board. It provides high density along with good heat dissipation and fast signal transmission, one of the main reasons it is ideal for modern electronics. However, it requires precise techniques of soldering in BGA manufacturing.