How to Make a Prototype PCB?

Creating a prototype PCB is essential to verify your design's functionality before full production. PCBX provides timely, cost-effective prototypes, allowing flaw detection and multiple design tests. Prepare your design specs, run prototypes, and smoothly transition to mass production.

Before committing to a full production run of printed circuit boards (PCBs) for your project, it is crucial to verify your design's functionality. To achieve this efficiently and cost-effectively, creating a prototype – a small batch of your design – allows you to test its performance.

However, a lengthy prototyping process should not deter you. Working with a PCB production business like PCBX ensures timely delivery of accurate and cost-effective prototypes. Once you are satisfied with your prototypes, we can effortlessly migrate to full production while maintaining the same level of quality and efficiency.

Understanding the PCB prototyping process is another critical component for a good experience. It gives you an idea for what to expect and enables you to easily submit the relevant information. So, what exactly is PCB prototyping about? Keep reading to find out.

Benefits of PCB Prototyping

We strongly recommend creating a prototype before ordering a full production run of a new PCB design. Our user-friendly and fast PCB prototyping service ensures you can test your board without delays or hassle. Here's what PCB prototyping enables you to achieve:

- Detect design flaws early in the production process, saving you significant capital investment.

- Cost-effectively test multiple design iterations.

- Gain an accurate representation of your board's functionality.

Before PCB Prototyping

Before starting the PCB prototyping process, evaluate if it aligns with your needs. While beneficial for many projects, it's not always necessary. If you decide to proceed with a prototype, gathering some basic project information is crucial to get started.

Deciding Whether You Need a Prototype

Prototypes are your valuable tools for testing designs and performing thorough quality checks on your circuit boards.

Here's a simple guide to help you decide:

New Design, New Project: Always use a prototype when starting a new project with a fresh design.

Proven Design: If you've successfully manufactured a product with a certain board design, you may not require a prototype for further production runs of that same board. However, any changes to the design or completely new PCB layouts necessitate a prototype.

Our Rapid Prototyping Service:

We offer rapid prototyping for test boards with up to eight layers, built using standard IPC-1 specifications and high-quality RF-4 material. Prototype orders typically range from 5 to 100 pieces with a turnaround time of 4-5 business days.

Once you're satisfied with your prototype, you can seamlessly transition to full production with more layers, different materials, and larger quantities.

Preparing for Prototyping

To submit your design or request a quote for our PCB prototyping services, we'll need some details about your design. The more information you provide, the more accurately we can design the prototype to your requirements. Here is a list of useful details:

- Number of Layers: How many conductive layers do you need?

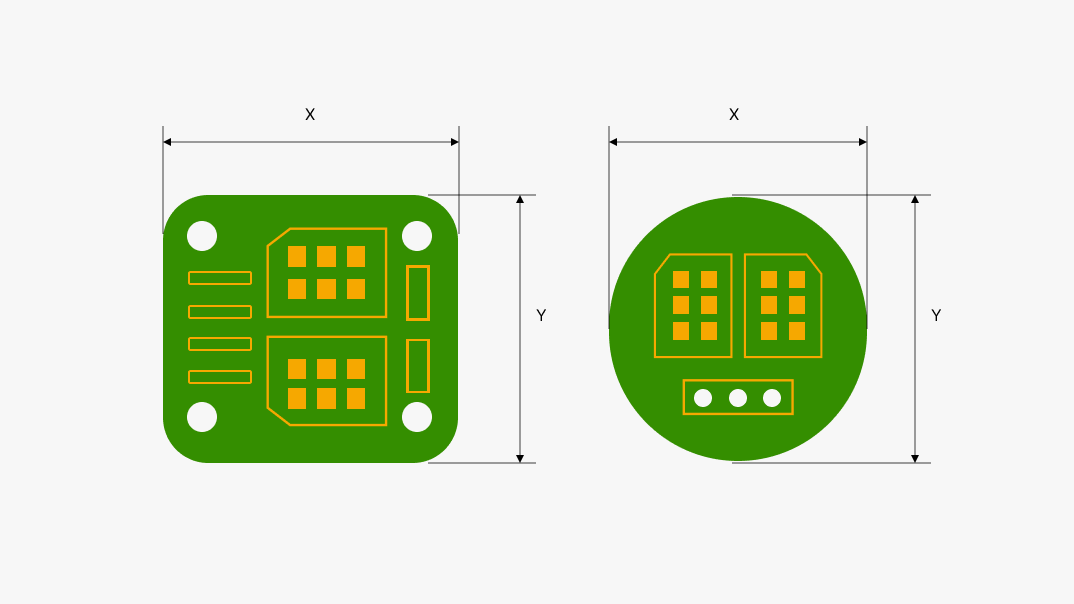

- Board Specifications: Define the board's thickness and dimensions.

- Conductor Specifics: Indicate the proper copper thickness and weight.

- Clearance and Size: Define the minimum trace width and spacing between traces, as well as the minimum hole size.

- Annular Ring: Determine the minimum distance between the hole and the nearest copper trace.

- Surface Finish: Select your preferred surface finish for your board.

- Soldermask and Silkscreen: Choose the color for the soldermask and silkscreen legend.

- Design Files: Provide your design files in any compatible software format. We'll convert them to the industry-standard Gerber RS-274X format.

For Gerber File Conversion:

- If you require us to convert your files to RS-274X, please ensure you include:

- Positive Gerber layers

- NC Excellon drill file

- Drill tool list

- Information on aperture size

PCBX looks forward to partnering with you on your next PCB project!

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

PCB prototyping is vital for testing and refining electronic circuits before mass production, ensuring performance and feasibility using methods like etching, milling, and 3D printing.

Creating PCB prototypes before full production avoids potential failures, saves costs, and ensures quality. PCBX offers rapid, accurate prototyping for efficient testing and design validation.

Prototyping PCBs is crucial for all designers and costs vary based on factors like board size, material, complexity, and urgency. Prices range from a few dollars to hundreds. Smaller batches cost more per unit.