How to Order Printed Circuit Boards?

Ordering PCBs involves defining needs, detailed documentation, sourcing strategy, and post-order management, while PCBX ensures top-quality PCB production.

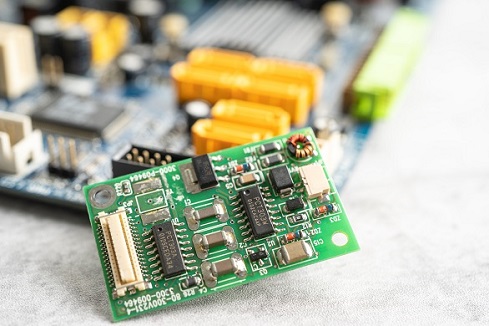

In the ever-changing world of electronics, printed circuit boards (PCBs) serve as the foundation for many products. Whether you're an engineer or a hobbyist, purchasing PCBs may be challenging yet necessary. This tutorial gives a thorough overview of how to obtain high-quality PCBs that are suited to your individual requirements.

Ordering PCBs requires knowledge mainly in two steps: the fabrication of the bare board and the assembly of components. Both stages have their expertise, and without extensive experience, especially with soldering, hand-assembling a PCB will result in very costly errors. This Calls for the need to partner with experienced professionals so as to ensure the output of reliable boards.

How to Order Printed Circuit Boards

The following is a step-by-step guide in ordering PCBs to have the best experience possible:

Define Your Needs: Prototyping vs. Full Production

The first decision is based on your order quantity. For testing and design validation purposes, keep 1-10 units as prototype batches. Prototyping will provide you with an opportunity to finalize the design aspects and functionality check for much quicker turnaround. Conversely, when your design is frozen, then full production applies-larger quantities and higher quality standards apply. Full production takes longer due to complexity.

Provide Detailed Design and Specification Documentation

Having detailed documentation ensures that the product is made correctly. Start design data with Gerber files, net lists, drill instructions, BOM, and diagrams of assembly; ensure the manufacturer is well coated with your intentions of the design. Material details should entail board thickness, the number of layers, type of material-which may be FR-4, copper thickness, and finishes such as ENIG or HASL. Impedance controls and tolerances should also be included. The number of boards also needs to be stated, besides panel size, hole dimensions, width of lines/ spaces, color of solder mask, and details about silkscreen.

Convey Any Particular Requirements

If your product requires more than the typical services, make sure to discuss these with your contract manufacturer from the outset. Examples might include certification, such as IPC or ITAR compliance, qualification tests, special handling requirements, or requests for a DFM analysis. This will ensure a seamless integration into your production plan by setting those expectations upfront.

Determine Your Component Sourcing Strategy

Talk about your preferences of component sourcing.You have three main choices:

Turnkey: The manufacturer sources all of the components, ensuring a hassle-free procedure.

kitted: You will arrange the parts. This method may lower prices, but it requires more logistical work on your part.

Combo: This is a flexible option in which you supply certain components and the manufacturer provides the rest.

How to Manage Post-Order Processes

An engineering review is frequently conducted once the specification is released and the quotation has been accepted. This can be one of the final times that you and your manufacturer confirm all the parameters before fabrication occurs. For many boards, after production, they are put through a series of tests to ensure that they match all of your design specifications.

The PCBs are then packaged after testing and shipped according to your logistics arrangements either to you or an appointed location directly. Communication is key at this point and along all points with your manufacturer to keep everything on schedule and head off potential problems before they arise.

How PCBX Can Help Order PCBs

PCBX is commited to the production of first-class PCBs, fabricated to specification with efficiency and reliability. Our services encompass material procurement, prototyping, assembly, testing, and complete system integration. From small batches for prototypes to larger volume batches for production, our staff here is ready to meet your requirements.

That experience is put into every project to ensure that no detail is missed and that expert care brings your electronic designs from concept into reality. At PCBX, you are partnering with a team that understands the details of PCB manufacturing down to the nuances, providing a seamless, top-class experience while meeting your demands with fast-delivered, outstanding results. With PCBX, you have the assurance that your PCB projects are the best they can be. That is because we design and build according to and often beyond industry standards. Contact us today and let us help you get your next electronic adventure started by being your partner in world-class PCB manufacturing.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

IC packaging is essential in electronics for protecting components, providing electrical connections, and managing heat. This tutorial explores its complexities, including its importance, various types like SMD, QFP, and BGA, and considerations for choosing the right package for specific applications. Proper IC packaging enhances PCB performance and reliability.

Key factors influencing PCB assembly cost include labor, turnaround time, quantity, technology, packaging, board size, material choice, layers, hole size, and finish. Manage costs by optimizing design, ordering in bulk, selecting suitable materials, and negotiating lead times.

Prototyping PCBs is crucial for all designers and costs vary based on factors like board size, material, complexity, and urgency. Prices range from a few dollars to hundreds. Smaller batches cost more per unit.