How to Reduce Noise in Analog Signals from PCBs

Reduce PCB noise for reliable analog signals with organized design, strategic layout, component selection, and targeted noise management techniques to enhance performance.

Analog signals, in today's world of electronics, form the backbone-right from audio equipment to sensor networks and highly sophisticated communication devices. But these signals are highly prone to noise, which in turn reduces signal quality, yields incorrect measurements, and sometimes deteriorates general performance. Noise emanates from EMI, a power supply, or improper layout of a PCB. The article is a comprehensive guide on how to effectively reduce and eliminate noise in analog signals from PCBs to ensure top performance and reliability.

Before one goes into noise reduction techniques, it is very important to understand what noise is and how it affects analog signals.

What is Noise?

Noise can be defined as any unwanted electrical signal that corrupts the signal of interest. Noise in analog circuits can take many forms, such as random fluctuations, spikes, or distortions. There are two main types:

External Noise: It is generated outside the circuit. For example, EMI emanating from other nearby devices and natural causes.

Internal Noise: It arises within the circuit itself, often due to thermal effects, component imperfections, or power supply issues.

Effects of Noise on Analog Signals

Noise acts on analog signals in the following ways: noise decreases SNR, making the signal indistinguishable from noise; it changes the shape and amplitude of a signal, hence making inaccurate measurements; it enhances data errors and deteriorates the quality of transmission in systems of communication; it deteriorates performance due to reduced sensitivity and dynamic range in analogue circuits.

Noise Source Identification in PCBs

To effectively reduce noise, the sources of noise have to be understood. Some of the common sources in PCBs are:

Electromagnetic Interference: External radio waves, power lines, or other electronic devices can penetrate into a circuit by radiation or conduction.

Power Supply Noise: Power supply fluctuation, ripples, and spikes in voltage can introduce noise, especially in mixed-signal designs.

Ground Noise: Poor grounding creates ground loops-discrepancies in the ground potential induce circulating noise.

Thermal Noise: This noise, also called Johnson-Nyquist noise, is due to electron movement within the parts and rises with temperature.

Crosstalk: Caused by signals on one trace interacting with other traces. This can be because of bad layout design.

Component Noise: The imperfections in components like resistors, capacitors, and op-amps introduce noise in a circuit.

Effective Noise Reduction Strategies

Noise reduction in analogue signals is all about good design practices, strategically selected components, and optimized techniques for PCB layout.

Optimizing PCB Layout

Segregate Analog and Digital Sections:

Divide the PCB into distinct sections of analogue and digital, preventing the incidence of digital noise interference. Allow separate ground planes for each section and connect at one point to avoid ground loops.

Minimise Trace Lengths: The analog signal traces should be kept short. Traces must be run perpendicular to each other to minimize junction noise or crosstalk.

Solid Ground Planes: Unbroken ground planes can lower EMI by providing low-impedance return paths.

Use Shielding: Metal enclosures and guard traces isolate sensitive analog signals from external noise.

Supply Noise

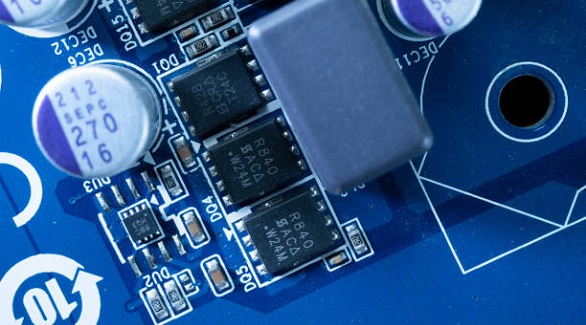

Utilize Decoupling Capacitors: Put decoupling capacitors around the IC power pins.

Linear Regulators: Low-noise linear regulators instead of switching regulators should be preferred for analog circuits, improving stability with low ripples.

Power Supplies: Analog and digital sections need separate power supplies to avoid the coupling of digital noise.

Grounding Techniques

Star Grounding: All the grounds shall be brought to a single point avoiding loops.

Ground Plane Designing: Design such that impedance will be low, giving a good signal reference, without unnecessary splits.

Filtering and Signal Conditioning

Apply Low-Pass Filters: The use of RC low-pass filters is very efficient in suppressing high-frequency noise.

Implement Band-Pass and Notch Filters: For isolating/enabling specific frequency ranges and the common interference frequencies.

Differential Signaling and Component Selection

Differential Signaling: This will help negate common-mode noise.

Low-Noise Components: The use of premium components such as low-noise operational amplifiers and metal-film resistors contributes to a low intrinsic noise increase.

Testing and Advanced Techniques

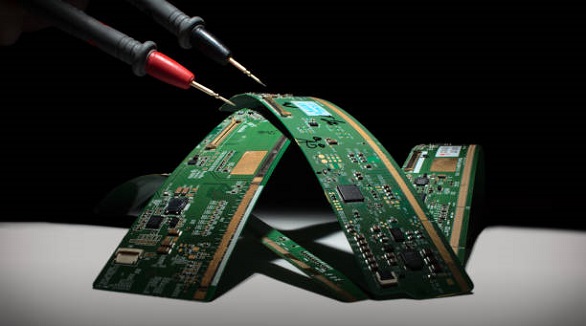

Once the mitigations against noise have been provided, extensive testing is needed:

Employ Oscilloscope Measurements: Employ oscilloscopes and spectrum analyzers to measure noise levels and find the source of noise.

Apply Eye Diagrams and Signal Analysis: The signal quality is tested for integrity, while impedance matching should be appropriate.

Advanced Noise Reduction Techniques

For high-sensitivity applications:

Apply Active Noise Cancellation: Use real-time feedback systems to cancel out noise.

Utilize Digital Signal Processing (DSP): Filter algorithms in the digital domain refine signal quality.

EMI Suppression Components: Ferrite beads and common-mode chokes are extremely effective at reducing high-frequency and common-mode noise.

Noise in analog signals is a pervasive challenge in electronic design, but it can be effectively managed through strategic PCB layout, grounding, filtering, and careful component selection. By understanding noise sources and implementing the strategies outlined here, you can design robust and reliable analog circuits, ensuring high-quality performance. Whether working with simple sensor circuits or on the most elaborate of mixed-signal systems, such techniques will lead to clean noise-free analog signals that guarantee your electronic projects operate with success.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

The dielectric constant in PCBs affects signal speed, integrity, and impedance, crucial for optimizing high-frequency circuit performance.

PCB corrosion degrades material, disrupts connectivity, and increases resistance. Prevent it with coatings, quality materials, and regular maintenance.

Addressing PCB bow and twist ensures reliability in advanced tech, focusing on intrinsic/extrinsic causes, refining design, and production for optimal performance.