How to Reduce PCB Assembly Cost?

Optimize PCB design, use through-hole vias, reduce layers, choose economical finishes, and minimize board size. Create detailed BOMs, order in bulk, avoid rush orders, ensure rigorous testing, compare providers, use automation, and consider turnkey services for cost-effective PCB assembly.

While trying to trim down the costs of PCB assembly without compromising on quality, several strategic ways will help in achieving this goal. From optimizing design elements to picking up the right services and components, every step opens up opportunities for cost savings. Here's how you can save money on your PCB assembly:

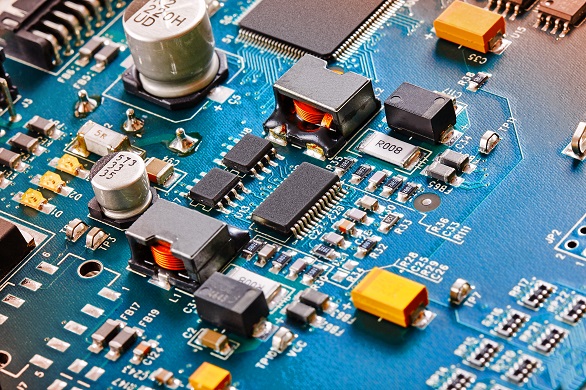

PCB Design Optimization

Proper PCB design can significantly help to minimize the assembly cost. Key design elements that impact the cost are via technology, layer count, surface finish type, and board size and shape. Here's how you optimize those factors:

Via Technology

You can also cut costs by using through-hole vias rather than their more complicated cousins. Blind and buried vias come in very useful in high density boards, but because they use more drilling and plating steps, they cost more. Where possible, use through-hole vias to save money.

Layer Count

Number of Layers—This is yet another parameter having a strong effect on the cost of PCB manufacturing. Multi-layer boards are more expensive than their single- or double-layer counterparts. Simplify your design by using the fewest layers necessary that will still satisfy all functional specifications.

Surface Finish Type

The type of surface finish on your PCB affects the cost. Indeed, high-performance surface finishes such as Electroless Nickel Immersion Gold are more reliable but costlier. For example, depending on the use, you can have an application that can get by with a cheaper finish like Hot Air Solder Leveling.

Size and Shape

The larger and more complex the PCB design, the more expensive it will be. Minimize the size and use simple shapes where possible to reduce material usage and the complexity of the manufacturing process.

Full Bill of Materials (BOM)

An elaborate BOM is important in cost housekeeping. It should include all components, their footprints, part number, reference designators, and alternatives if possible. A detailed BOM enables sourcing of components more effectively and helps avoid the component shortage that might lead to delays or extra costs.

Order Time and Quantity

Order Volume

Higher order volumes have economies of scale which decrease the cost per unit. When you place a bulk order, you are able to spread the set-up and programming costs over more units which lowers the cost for each PCB.

Timing

Avoid placing any rush orders. Plan out your orders well ahead of time and allow plenty of lead time for manufacturing. This strategy ensures you avoid expedited shipping and rush production fees, which can add up quickly.

Inspection and Test

Compromising on the quality of the PCB to cut down cost is not at all acceptable. Rigorous inspection and testing guarantee reliable performance and longevity without additional costs due to rework or product failures. Monitor the thermal behavior of traces and let the circuit adapt to changing conditions to reduce long-term risks.

How to Choose an Affordable PCB Assembly Company

Compare Prices

Different PCB assembly firms charge differently. Compare several providers to find one that has quality services at reasonable prices. Value-added services with low minimum order quantities and discounts for large projects are salient features to look out for.

Reputation

While cost is important, it should not come at the expense of quality. Check the credibility of any prospective firms through reading reviews and testimonials. Very few people would bargain for a cheaply priced service at the cost of poor-quality PCBs resulting from such services.

Utilize Automation in PCB Assembly

Automation vs. Manual Assembly

While these automated PCB assembly machines are expensive upfront compared to manual assembly, they have proved to give long-term savings. Automation reduces labor costs because of its increased production speed and fewer human errors, therefore providing improved product quality and reduced rework.

Efficiency and Consistency

Automated assembly machines can place and solder components with less time and variation than human operators. This is much more expensive at the front end compared with making it up in labor savings and quality over the long haul.

Growing the Number Ordered

Increased Quantity Job

One of the strongest ways to reduce the cost of PCB assembly is by the quantity of your order. More significant orders spread the set-up fees over more units, qualifying for bulk discounts and bringing down the cost per board.

Negotiate with Vendors

Make sure at all times you have the bandwidth to handle a large order and negotiate the discount with your vendor. Not all businesses can handle large orders, so verify this beforehand.

Optimize the PCB Assembly Design

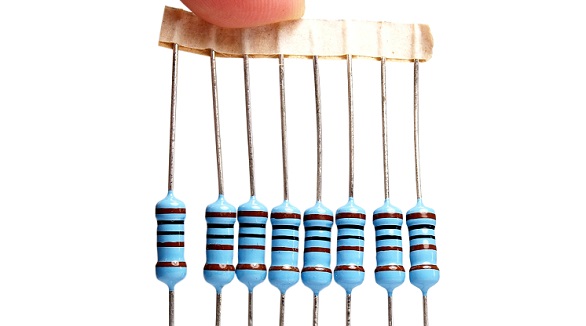

Surface-Mount vs. Through-Hole

Generally, Surface Mount Technology occupies less space and uses less material than Through-Hole Technology and is, hence, cheaper. Design your PCB for SMT, wherever possible, to help reduce the overall assembly cost.

Reduce Holes and Layers

Holes and layers affect both the material cost and the assembly time. Lessen the number of vias and layers; the more straightforward the design, the better.

Standard Components

The use of standard and off-the-shelf components reduces cost and allows quicker times to assemble—avoiding custom or hard-to-find parts that increase the expenses of production and create delays in production.

Consider Turnkey PCB Assembly Services

Engagement of a turnkey PCB assembly service, which takes care of everything from component sourcing to the final assembly and testing, can simplify the manufacturing process and reduce its cost. While sometimes a bit more expensive upfront, the turnkey services actually save time and money by taming the entire process.

Conclusion

The ways of reducing PCB assembly costs include low-cost services, increasing the order quantity, optimizing design, and using automated manufacturing. Ensure that these ways to cut down on costs do not impact the quality and functionality of a PCB. That means that reducing costs while keeping the goodness of a board for the application is intended to be used for calls for a balanced approach on every project.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Key factors influencing PCB assembly cost include labor, turnaround time, quantity, technology, packaging, board size, material choice, layers, hole size, and finish. Manage costs by optimizing design, ordering in bulk, selecting suitable materials, and negotiating lead times.

PCBX offers fast, high-quality turn-key PCB prototype assembly services, including fabrication, component sourcing, and testing, all at competitive prices, to accelerate product development.

Customers prefer one-stop PCBA service not only because of price transparency; it can save time and reduce labor costs with efficiency and professionalism in procurement and production.