IPC-A-600 Standard for PCBs

IPC-A-600 standard guides PCB quality through three class levels, ensuring durability and reliability for diverse applications, crucial for manufacturers.

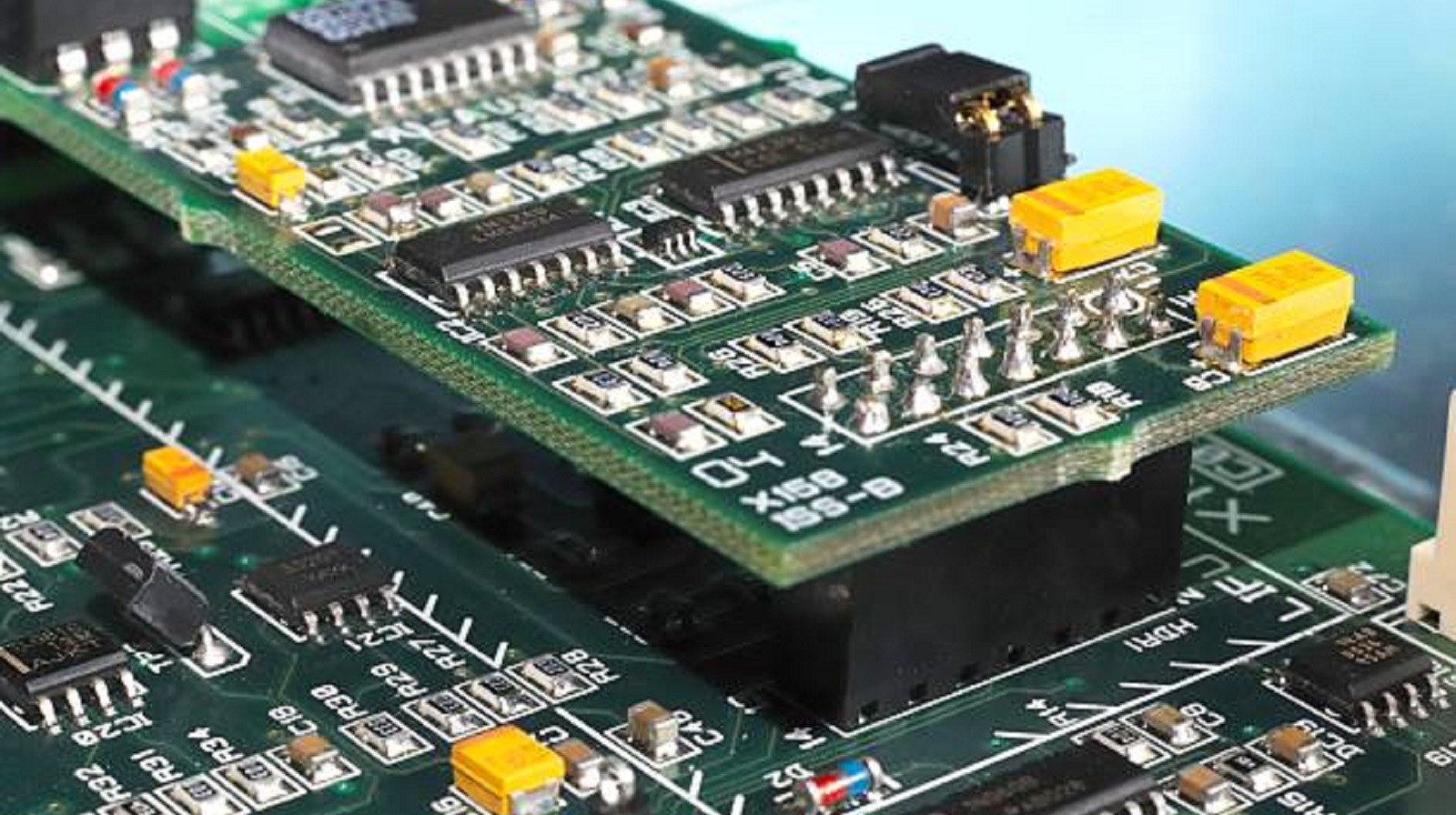

In the complex world of electronics manufacturing, ensuring that printed circuit boards meet strict quality and reliability standards is paramount. The IPC-A-600 standard, officially known as "Acceptability of Printed Boards," is a critical resource in this arena, offering detailed guidelines for assessing the quality of various PCB types. As a leader in the manufacturing of PCBs, it is important that PCBX complies with these standards to ensure our products surpass industry expectations.

IPC-A-600 was developed by the Institute of Printed Circuits, IPC, to stipulate comprehensive acceptability criteria of PCBs. These help in ensuring the continued reliability and functionality of electronic assemblies within a wide field of applications. At the heart of its purview is establishing various acceptance levels, providing detailed observation of internal and external quality of the PCB, and setting up industrial benchmarks that will help PCB manufacturers make high-quality, consistent boards.

Classification of IPC-A-600

IPC-A-600 is unique in the three-class system of categorizing PCBs based on application and required quality. It ensures that the manufacturer is able to choose the proper quality and acceptance criteria to meet their specific needs:

Class 1: General Electronic Products

Class 1 encompasses disposable electronic products that happen to have relatively short useful lifetimes, such as toys and children's items as well as LED lighting. Such applications do not generally call for high reliability or long life.

Minor defects within such a class are permitted provided they do not seriously impinge on functional ability. Class 1 boards, in this regard, are pretty economical of costs for large-scale productions, where cost is important.

Class 2: Dedicated Service Electronic Products

Class 2 is targeted at electronics requiring better performance and longer life expectancy such as mobile phones, computers, and telecommunications equipment.

Minor cosmetic defects are permitted, but these boards are supposed to be more reliable than class 1. These equipment utilizing these boards are also not subjected to extreme environmental conditions; however, their operation should be consistent and reliable.

Class 3: High-Performance/Harsh Environment Electronic Products

Class 3 represents the highest class of PCBs intended for or used in applications where high reliability is required, such as military, aerospace, and medical.

Due to the critical nature of their usage, Class 3 boards are subject to the most stringent inspection and testing to ensure faultless performance even under extreme conditions. These boards are designed to operate under extreme environmental and operational stressors.

Avoiding PCB Imperfections

One of the major goals of the IPC-A-600 standard is to minimize visible and invisible imperfections in PCBs; if not minimized, some of these imperfections lead to malfunctioning and have an impact on electronic reliability:

Internally Observable Conditions: These would include internal defects or those defects that are design-related; examples include blisters and voids. These conditions, in most cases, require microscopic examinations for the identification of such problems to ensure the construction internally is acceptable.

Externally Observable Conditions: Surface defects are measured visually. The inspection of these surface attributes enables the detection of some defects that may well reduce functionality or lifetime for an assembly.

The quantification of these defects enables a logical, structured approach towards corrective action by the manufacturer on improving the reliability of the final product.

Class 2 vs Class 3

While Class 2 and Class 3 are in the middle of many applications, they have some drastic differences in production, inspection, and design standards:

Manufacturing Considerations: Class 2 boards are conducive to mass production, making them cost-effective without compromising essential quality. In contrast, Class 3 boards demand a higher level of precision and error-free manufacturing processes, often at additional cost.

Test Methods: The inspection of class 3 boards involves more rigid testing, like vibration and environmental stress and thermal testing than class 2, which are simpler and cheaper inspection processes. These tight test protocols make class 3 boards meet their strict reliability criteria.

Design Rules: Class 2 design specifications aren't as strict, with allowance for functional requirements such as via and plating, whereas class 3 really clamps down on having stringent attention to component placements and layout designs to enable performances at optimum and failures on the low.

Assembly Processes: Whereas both classes use SMT, Class 3 needs the highest level of accuracy in component placement, and even minor visual defects are not allowed since they could affect performance.

Advanced Compliance: Class 3 and Beyond

Due to the special uses these boards see, Class 3 boards are fabricated to advanced standards such as IPC-6012E for environmental and mechanical resistance against stressors common to military and medical applications. This includes:

Extended Testing and Compliance: IPC-6012E further elucidates additional testing and acceptability criteria, including parameters very vital in stressful conditions such as thermal cycling and resistance to vibration.

Specialized Use Cases: Specifications extend to areas where it would be absolutely unacceptable to make mistakes in general, such as in military avionics and healthcare.

The IPC-A-600 standard is indispensable in the process of manufacturing Printed Circuit Boards; it serves as common ground where stakeholders can maintain and improve quality. By sticking to these standards, manufacturers are guaranteed that their PCBs will meet or even exceed industry expectations and foster reliability in the many applications they are put on. At PCBX, we incorporate these standards into our production processes to ensure that we deliver products that meet and often surpass client specifications.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

IPC standards ensure PCB quality by guiding solder mask application, focusing on material properties, performance tests, classifications, and coverage criteria.

The trend towards lead-free PCB manufacturing comes due to the EU's ROHS directive, which requires compliance to the limits on the content of lead. Compliance with lead-free is achieved by different surface finishes such as ENIG, ImAg, ImSn, and OSP—all with their different pros and cons. This paper compares these finishes to help choose the best for specific PCB applications.

The article explains the current situation of Printed Circuit Boards and future development based on efficient production helped by advanced software and manufacturing processes. Future technological developments are in store for 3D Printed Electronics, flexible PCBs, eco-friendly biodegradable PCBs, and board cameras. It elaborates on other powerful automation tools that are going to make the entire PCB design process efficient in the near future. All of them will further improve and develop with the technological advances in PCBs, keeping up with the ever-increasing industry and consumer demands.