IPC-A-610 Standard: A Crucial Guide for PCB Assembly

IPC-A-610 ensures global standards for PCB assembly, covering component placement, soldering, labeling, and training, enhancing quality and reliability.

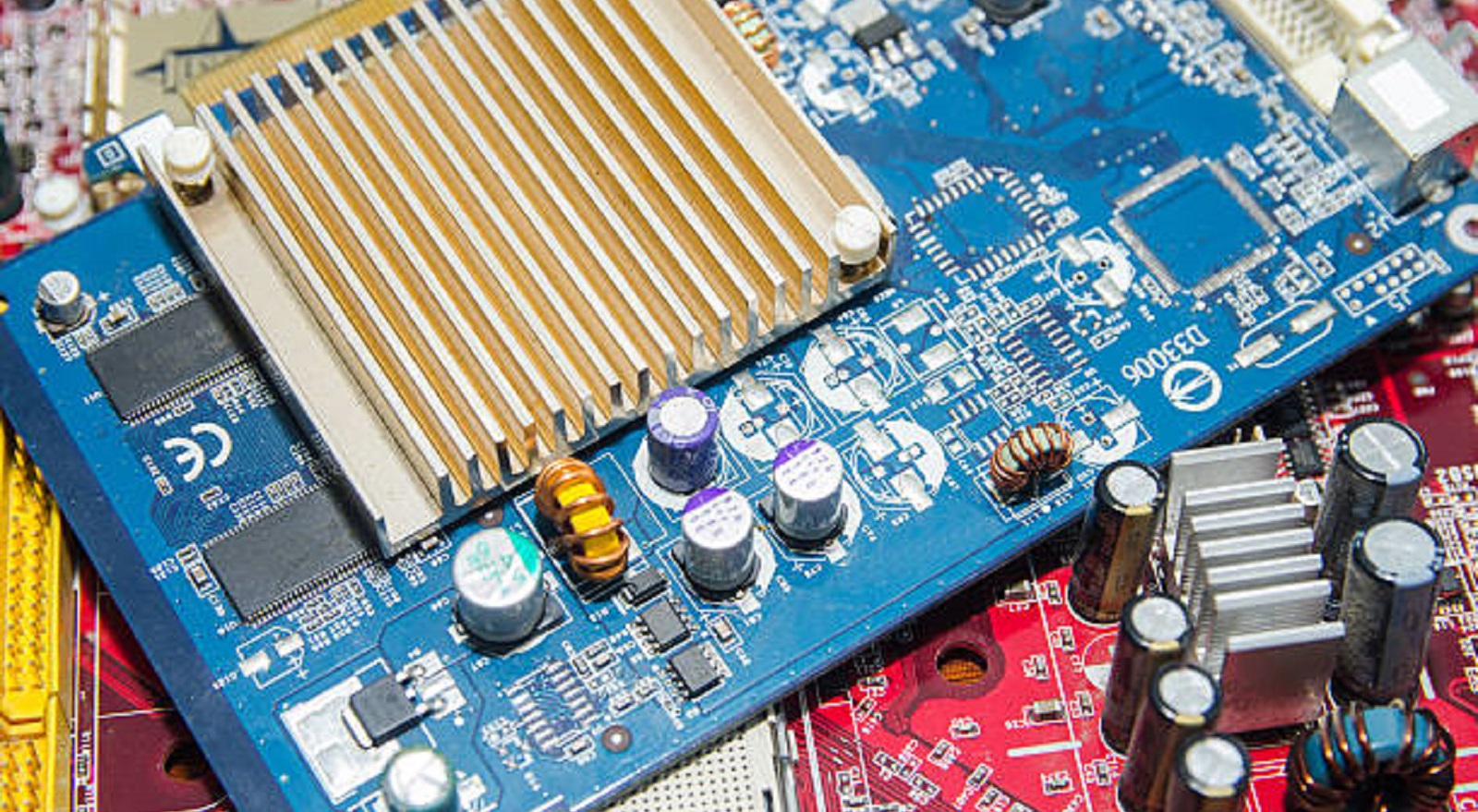

In the ever-evolving world of electronics manufacturing, quality and reliability are axiomatic. At PCBX, where we differentiate through high-quality printed circuit boards (PCBs), compliance with time-tested standards like IPC-A-610 is of primary importance. The established worldwide standard offers in-depth coverage of acceptability of electronic assemblies and represents standard reference work on quality control within the industry. This article shall discuss the IPC-A-610 standard in great detail, covering its significance, application, and advantage it presents to PCB assembly.

The IPC-A-610 standard was first created in 1983 by IPC, the Association Connecting Electronics Industries. It has since been updated many times to accommodate evolving technology and manufacturing practices, with the latest revision being IPC-A-610G, which was published in 2020. This demanding standard specifies visual acceptance criteria for a range of processes including component placement, soldering, cleaning, and marking so that electronic assemblies are both functional and attractive.

Key Elements of IPC-A-610

For assembly of PCBs, IPC-A-610 standard contains standards that are necessary to deliver the best quality. The following are necessary for its application:

Component Installation: Good PCB assembly is based on proper installation. The standard lays down rules for the correct orientation, spacing, and alignment of components. In both through-hole and surface-mount technology, avoiding mechanical interference and allowing enough space for easy testing and assembly is the emphasis.

Soldering: Consistent soldering is the secret to successful electronic assemblies. IPC-A-610 prescribes stringent standards for solder joint formation with a bias towards regular, even joints free of voids and with a small quantity of solder. The ideal solder joint would be a uniform concave fillet indicating good wetting of pads or lead surfaces.

Cleaning and Coating: The standard also addresses post-solder cleaning to remove contaminants that could jeopardize assembly reliability. It also has voluntary conformal coating guidelines to offer additional protection against environmental factors such as moisture, dust, and chemical exposure.

Marking and Labeling: Labeling facilitates component identification and traceability—critical to quality control and conformance. IPC-A-610 guarantees legibility, wear resistance, and correct placement of marks on PCBs and components, helping with accurate assembly and testing.

Significance of IPC-A-610

For companies like PCBX, adherence to IPC-A-610 is essential for compliance purposes as well as producing high-quality, dependable electronic assemblies. And that's because:

Consistency and Reliability: It provides a standardized system on which manufacturers can rely for consistent and reliable production of products. Consistency is especially crucial in industries that require high precision, such as aerospace and telecommunications.

Worldwide Acceptance: As an international standard, IPC-A-610 facilitates worldwide acceptance and lays down conditions for international trade and cooperation since it provides similar quality standards across the globe.

Quality Assurance Instrument: It is also a chief quality assurance instrument that helps catch defects and problems of workmanship early in the production process and hence save resources and time.

Training and Certification: The standard facilitates training programs that attest to the staff being competent and current with regard to the practices and standards adopted in the field.

Implementation and Challenges

Following IPC-A-610 comes with its attendant challenges, particularly in the fast-paced age of technological progress. Maintaining an eye on its updates requires persistence in training and learning. What is more, costs of implementation may differ, and there can be the difficulty for small producers to find such financial strain following such demanding requirements.

But the cost of IPC-A-610 compliance is ultimately worth it. By minimizing the incidence of defects and overall product unreliability, it enhances customer satisfaction and could potentially drive more solid business results.

Role in Quality Assurance and Training

IPC-A-610 not only specifies the standards but also sets the groundwork for industry personnel training and certification. PCBX conducts in-house training based on IPC-A-610, making our staff up to date with the latest knowledge and skills required to meet industry standards. Certification not only inspires confidence in the clients regarding our commitment but also allows our workforce to perform work of superior quality efficiently.

Training Courses: These involve comprehensive topics outlined in IPC-A-610, combining classroom instruction with practical training to provide comprehensive knowledge of quality standards.

Levels of Certification: Offering multiple levels of certification, the program allows staff to specialize according to roles and responsibilities, so that all-around expertise is guaranteed.

Continuous Learning: Recertification is encouraged, rendering individual knowledge current and in line with the new industry standards and practices.

Future of IPC-A-610

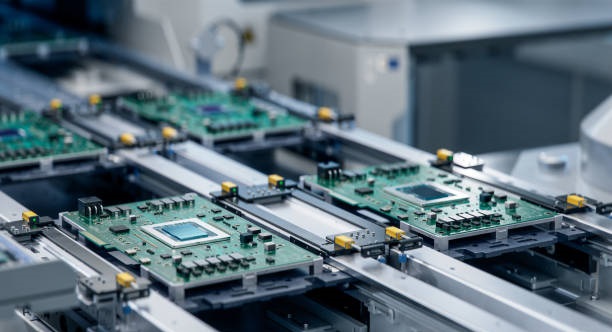

In the future, IPC-A-610 is sure to go through more adjustments to accommodate the ever-changing needs of the electronics industry. We anticipate these changes to address innovation like miniaturization, integration of robotics assembly processes, and integration of new materials into electronic products. With it evolving, so will PCBX, accommodating these changes so that we remain at the cutting edge of high-quality PCB manufacture.

At PCBX, we recognize that the IPC-A-610 standard is not just an industry standard; it is a cornerstone of our pursuit of manufacturing excellence. By creating a specific model for component placement, soldering, cleaning, and marking, it sets the bar on quality, performance, and reliability of electronic assemblies higher. By rigorous compliance and proactive training, not only do we meet but surpass customer expectations and industry standards. Embracing IPC-A-610 assures that in the future, PCBX will continue to deliver the superior quality PCBs with which our name is synonymous, thus corroborating our commitment to excellence in the dog-eat-dog world of electronics manufacturing.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

IPC Class 2 offers cost-effective reliability for non-critical electronics, while Class 3 ensures high-reliability for critical applications, at higher cost.

IPC standards ensure PCB quality by guiding solder mask application, focusing on material properties, performance tests, classifications, and coverage criteria.

With SMT assembly at the forefront of electronics manufacturing, advanced inspection technologies like visual, AOI, ICT, and X-ray are essential due to increasing component complexity. Inspections throughout all stages—incoming, process, and post-reflow—address defects, ensuring quality and reducing rework.