Load Current in PCB Circuits

Effective management of load current in PCBs ensures reliability and safety, essential for modern technology across sectors like communications and medical devices.

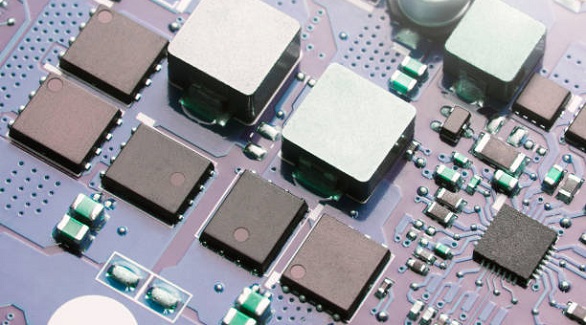

Technology, perhaps one of the most revolutionary creations by humans, has changed everything about our lives. We have seen the development of technology in steps that have taken us through this age of convenience and luxury. Among the many contributors to this development, and indeed one quite crucial to this modern world for the operation of devices and more, is the printed circuit board. These complex boards form the backbone of electronic devices without which life would have been very different. A key factor in the successful utilization of their potential is the understanding and management of load current within the circuits of a PCB.

The Core of Load Current

Load current is essentially the quantity of electrical current supplied by a power source to the components on a PCB. These components utilize this current to carry out all the functions, right from simple calculations to more elaborative operations. This current, however, must be managed because the excess of this beyond what the power can supply leads to overheating and short circuits that may damage connected devices beyond recovery. In order for safe and efficient operation, the behavior and impact of the load current have to be well understood.

The Importance of Load Current in PCB Design

Computer boards are crucial parts of anything from simple consumer electronics to complex military systems. Because of their proper management via the load current aspect, these devices can function reliably even under extreme conditions. When designing a PCB, the current bearing is important in the following areas:

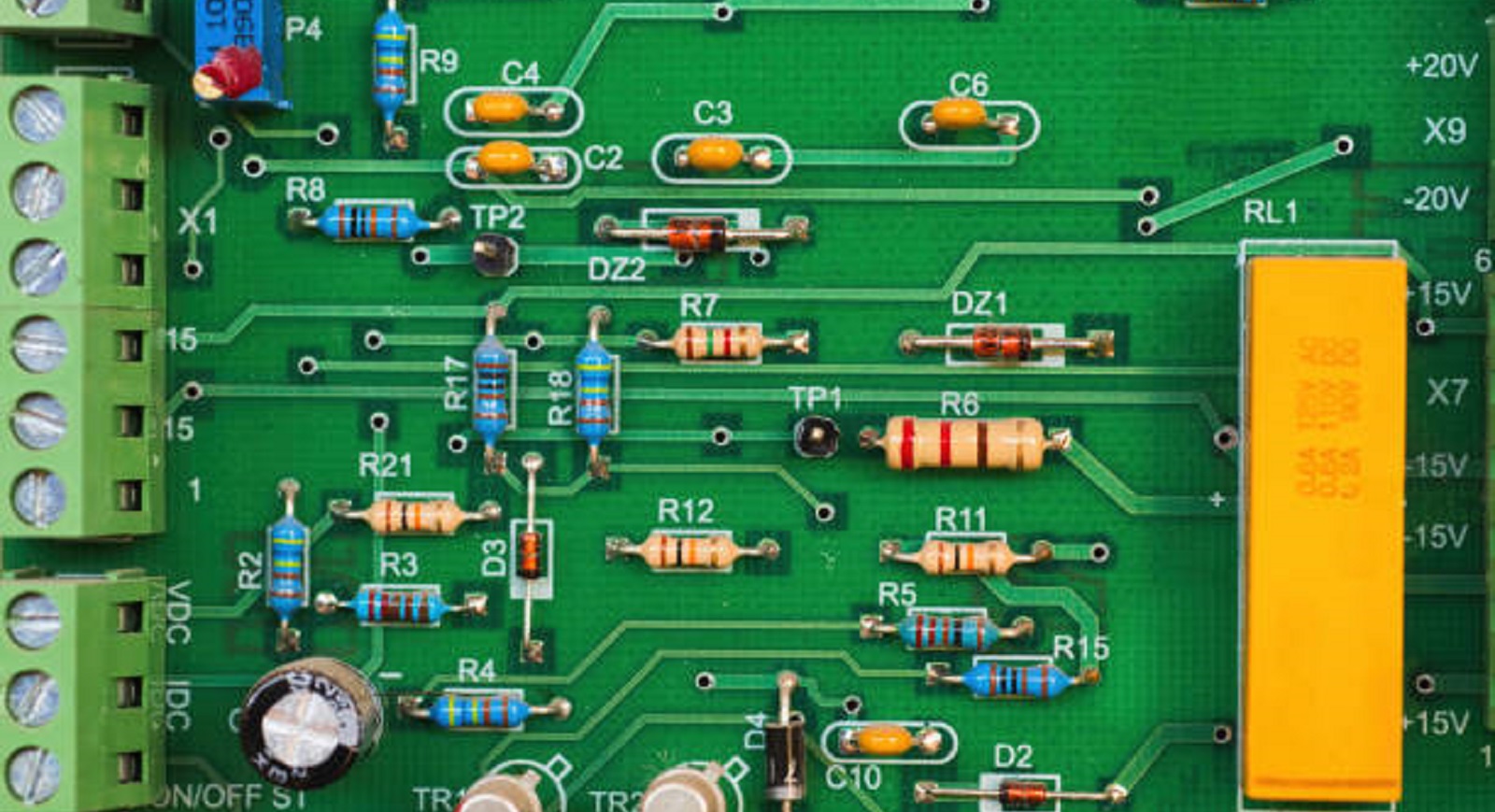

Component Selection: Given that the load current is predicted, component selection needs to be predicated on this. Taking into consideration the peaks in transistors, resistors, and connectors is necessary to guarantee reliability.

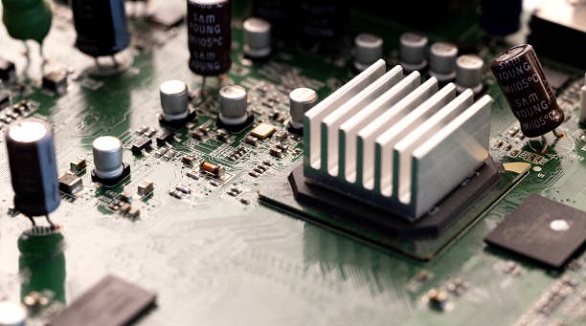

Thermal Management: Abnormally high load currents generate heat as well. Through heat sinks, methods such as thermal vias and copper pouring may be widely employed to disperse excess heat.

Power Supply Considerations: Regardless of the circumstances, a power supply needs to be able to generate a load current. Lack of capacity would surely cause the system to malfunction and stop working.

Signal Integrity: Excess current may cause voltage dips along PCB traces, which can impair signal integrity and result in errors, especially in digital circuits.

Operational Safety and Compliance: Which again helps to minimize failures and other dangers, are made possible by properly designed circuits that handle load current and comply to national, international, or industrial standards.

How Load Current Operates within PCB Circuits

For PCB design, it is essential to comprehend how the load current may affect various circuit components and systems. The electrical current that is drawn by devices that are connected to a power source is known as load current. It is important that the power supply's capability be matched with the load requirement of connected devices to avoid overloading.

Several factors affect load current in a PCB circuit, including:

Load Demand: Which can be from more than one component on a given PCB with variable power.

Temperature Variation: Provide more current to certain components and will affect the overall dynamics of load.

Impedance and Path Resistance: The physical properties of the PCB TRACE resistance and impedance come directly into play to determine load current.

Simulation Tools for Load Current Analyses

Simulating the load current behavior is an important stage in PCB design. Advanced simulation tools, like as PSpice, enable engineers to simulate how load currents impact signal behavior in complicated circuits. Creating exact simulations allows designers to predict future challenges, such as:

How impedance impacts transmissions at various frequencies and time scales.

How load fluctuations affect voltage drop and heating.

Identifying stress areas in the circuit that may cause failure.

Using such simulations, PCB designers can optimize trace layouts to ensure reliable power distribution among circuits.

Differentiating Load Current from No-Load Current

For industrial applications, the differentiation between load current and no-load current is important in the following ways for power system design:

Load Current: Amount of active power that a device requires when it is operational. It allows specifying the power supply appropriately and scaling components correctly to operate under demand.

No-Load Current: This is the amount of current an appliance consumes when not operating its main function, mostly during an idle state. This becomes very important during sizing of power supplies because it gives the minimum consumption when devices are not in use.

Both specifications are important in the design of systems to ensure that they can support operational and standby states without running into overload or over-consumption of energy.

Applications and Implications

Effective load current management extends into every facet of technology-dependent sectors, including:

Communication Systems: With the need to assure exact power delivery to eliminate data loss.

Military and Aerospace: Designing for extremes to keep up reliability in critical operations.

Transportation: Power control systems in vehicles require precise current management to maximize safety and dependability.

Medical Devices: To ensure lifesaving equipment stays within performance standards under all conditions.

Thus, understanding the influence of load current in these applications underlines its importance in the development of robust and durable electronic systems.

Within our increasingly interconnected world, the function of PCBs is much more important as basic technological enablers. How load current is managed in these boards makes sure they work safely and efficiently, underpinning the dependability of modern-day technology. Since load current is the cornerstone of how a PCB functions, its nuances allow the engineer and designer to innovate beyond the technological envelope. At PCBX, we believe in providing the insights and solutions that empower designers to create innovations that continue shaping the future. For commercial, industrial, or personal use, effective load current management stays at the heart of today's electronic marvels.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Capacitive circuits store and release energy, stabilize voltage, filter signals, and manage power flow, making them vital for modern electronic systems.

eFuses are advanced PCB fuses that reset automatically, offering fast, precise protection and versatility in electronics, enhancing device safety and reliability.

Capacitors are crucial in circuits for storing energy. Testing methods include in-circuit and out-of-circuit using digital multimeters, ESR, and LCR meters. Proper testing ensures reliability and prevents malfunctions.