Mastering Flux Removal from PCBs

Flux removal is essential for PCB reliability, preventing corrosion and supporting coatings, using isopropyl alcohol or other methods for high-quality manufacturing.

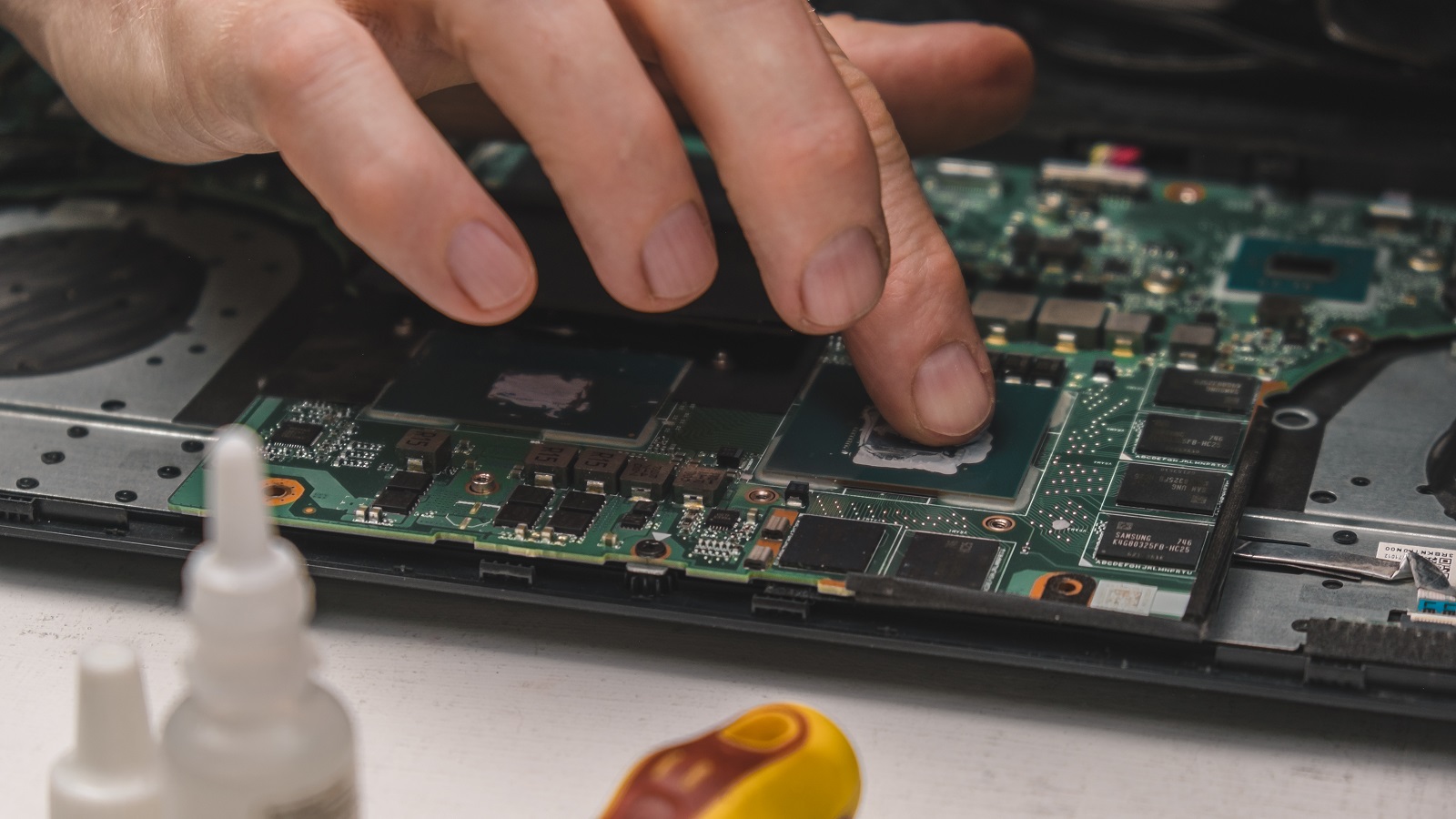

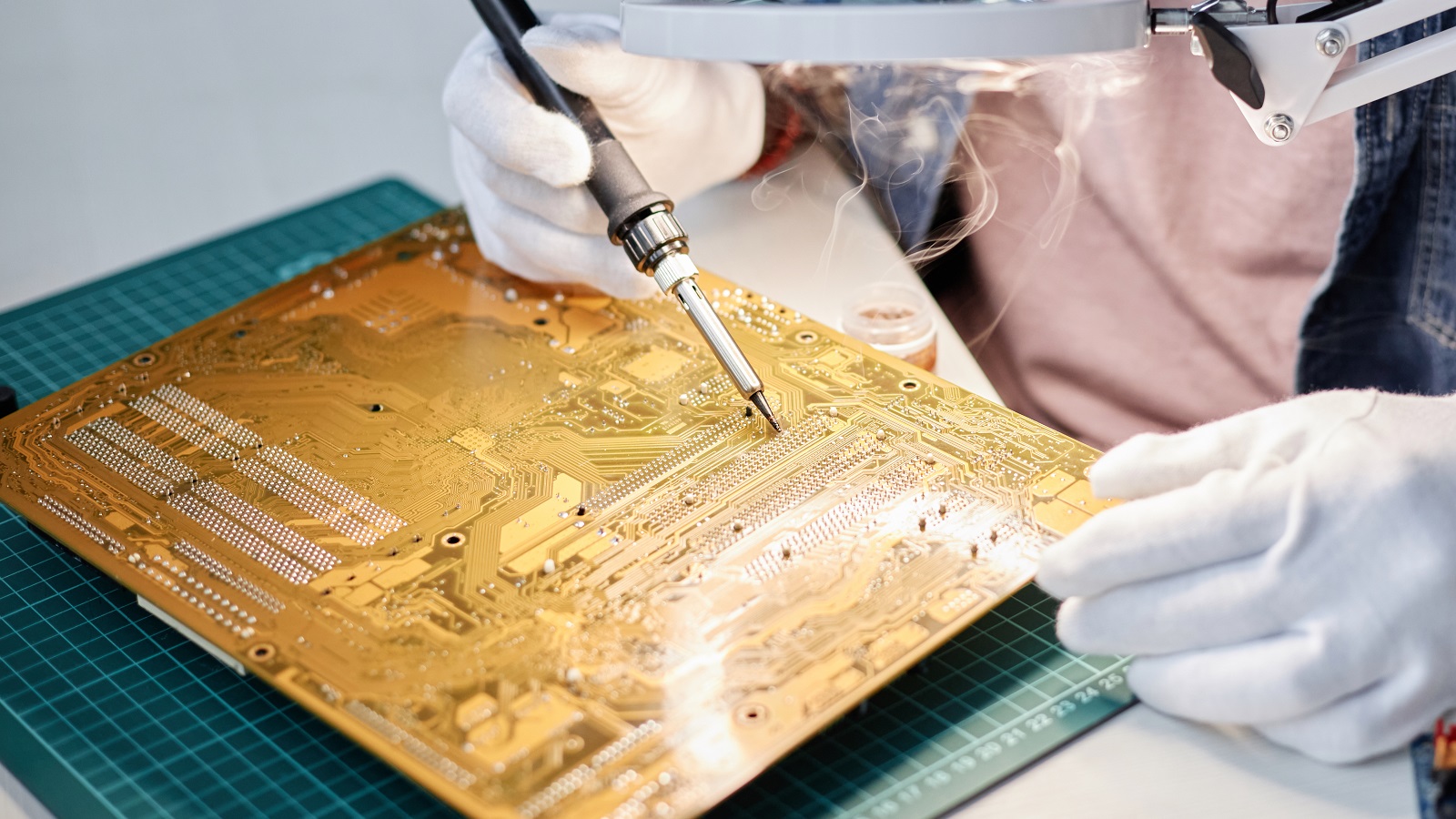

The quality of printed circuit boards in the world of electronic manufacturing has a say in the overall performance and reliability of any electronic gadget. At PCBX, we support intensive post-production procedures, specifically the important process of flux removal after soldering. Flux is a special chemical substance used during soldering electronic components onto the circuit boards; it provides cleaner joints by removing the oxides and impurities. After soldering, the residual flux needs to be removed to avoid future problems and achieve quality in the production.

Importance of Removal of Flux

Flux residues, if left unattended, present a number of risks: the potential for acidity, inducing corrosion over time, possibly affecting the connections on the PCB; and even when "no-clean" fluxes are used, designed to minimize the residue, they can still interfere with subsequent processes including the application of conformal coatings. Conformal coating is important for:

Improved Reliability: A flux-free PCB is more reliable and less likely to have unexplained failures, which, in aerospace or medical devices, can be considered critical.

Avoid Corrosion: Flux residues have the tendency to attract moisture, which can lead to corrosive damage and destroys the structural and functional integrity of the board.

Aesthetic Improvement: A clean, residue-free PCB is also aesthetically appealing and reflects well on the manufacturer, instilling a sense of confidence in the clients on the quality of the components.

Conformal Coating Compatibility: Residues on the board can inhibit the adhesion of conformal coatings and may expose the PCB to environmental degradations.

Dendritic Growth Prevention: If ionic residues are left behind, they can give rise to the growth of conductive dendrites, which could pose a threat in terms of electrical shorting or leakage of current.

Flux Types and Understanding Their Impact

The type of flux will determine the cleaning method because of differing composition and levels of activity:

It finds its most common application in manual and automated soldering. Rosin flux normally leaves visible residues that have to be cleaned properly to avoid corrosion.

No-clean flux is designed to leave minimal residues but can still be cleaned when other coatings are applied on the same area or it is used in high-reliability applications.

Water-soluble flux provides a more powerful cleaning action and gives better soldering, but its residues are corrosive and need to be completely washed off to avoid damage.

Effective Methods of Flux Removal

Methods for the removal of flux from PCBs are related to the type of residue, amount, and particular need of the specific PCB. Some effective methods include:

Cleaning with Isopropyl Alcohol

IPA is usually the preferred method of cleaning any flux, as it is very effective and evaporates relatively fast. To clean effectively, the following should be done:

It should be above 90% concentration.

Wear gloves and work in a well-ventilated area to avoid any safety concerns.

Take a soft-bristled brush, such as a soft-bristled toothbrush, wetted with IPA and gently sweep flux residue off the board.

After scrubbing, clean the area with a lint-free cloth to absorb excess alcohol and the dissolved residues.

Specialized Flux Cleaners

From such companies as Surclean, come products, which are stronger cleaning solutions and which boast of longer working time since the evaporation rate is slow:

These cleaners can be applied via spraying; mechanical brushing is achieved to ensure complete cleaning.

The residue must be washed off with extra cleaner applications to ensure the removal of all remaining parts.

Water and Saponifier Method

In the case of water-soluble fluxes, a good wash with warm water is essential:

The incorporation of saponifiers into the wash helps in neutralizing acids and forming compounds that get washed away easily.

A good enough rinse cycle must be used to remove all residues completely in order to avoid corrosion.

Immersion in Poly Clens Solution

A new method of immersion in solutions such as Poly Clens makes the removal process much easier:

Just dip the PCB into the solution and stir it gently, so cleaner can dissolve the residues without mechanical force.

Rinse with distilled water afterwards and dry the board with a heat gun.

Conclusion

At PCBX, we take protecting and preserving the longevity of your PCB assemblies as our mission. The effective removal of flux is at the heart of ensuring integrity and high quality in PCBs for critical applications. Whether it be a proper cleaning methodology-play it safe with isopropyl alcohol or play it effective with specialized cleaners-all these go to contribute toward attainment of very high standards of operational excellence and reliability from the manufacturers. Come to think of it: trust PCBX as your partner in delivering cutting-edge PCB solutions where precision and attention to detail are enshrined as guiding principles.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Copper in PCBs oxidizes, causing solder defects and reducing product life. Surface coatings like HASL, OSP, ENIG, and ENEPIG prevent this, ensuring solderability and reliability. Choosing the right coating based on application needs significantly improves the quality, reliability, and lifespan of products.

Conformal coating protects PCBs but sometimes needs removal. Local removal uses soldering, solvents, or mechanical abrasion. Full removal is more labor-intensive, involving chemical stripping or extensive mechanical abrasion.

Soldering forms a very important part in the assembly of a PCB. Wave soldering is ideally applied in Through-Hole Technology, while reflow soldering in Surface Mount Technology. Wave soldering involves flux spraying, pre-heating, soldering, and cooling, while in the case of reflow soldering, pre-heating, thermal soak, soldering, and cooling steps are applied. Temperature and time control are the two most critical parameters in the above-mentioned techniques for ensuring soldering reliability.