Metals with Low Thermal Conductivity

Low thermal conductivity metals, like stainless steel, are ideal for heat retention in PCBs, aiding thermal insulation, efficiency, and stability in electronics.

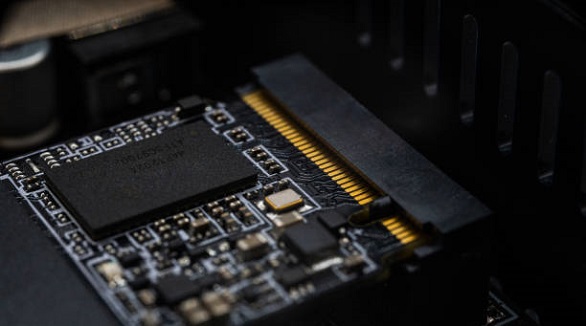

Within electronics and especially the field of PCB, thermal management is one of the keys to either good design or proper functionality. While metals are highly valued for high thermal conductivity, allowing for facilitation of heat in an effective way, there is a subset of them regarded for low thermal conductivity. This makes them good thermal insulators, which may be quite essential for use in applications where holding the heat inside a system is just as crucial as losing it.

Thermal conductivity defines the degree at which a given metal can conduct heat. Those metals with high thermal conductivity-such as copper and aluminum-have become synonymous with fast heat transfer and find application in processes where effective dissipation of heat is required. Low thermal conductivity metals are used for applications where heat retention is beneficial as they act as insulators. Every time a certain metal is in question for application to something, especially electronic systems, it needs to be evaluated concerning its thermal properties among other factors, like mechanical strength or resistance to corrosion.

Low Thermal Conductivity Metals

Let's turn our attention to some of the metals that have low thermal conductivity, which sometimes becomes a definite advantage for many engineering applications, including printed circuit boards:

Stainless Steel

Stainless steel has a relatively low thermal conductivity at approximately 15 W/mK. In the conduction of heat, this is the poorest conducting metal compared to other common engineering metals like copper and aluminum, which have very high thermal conductivities.

The poor thermal conductivity of stainless steel makes it an excellent choice for many high-temperature applications wherein the need is more for heat retention rather than rapid dissipation.

The mechanical properties and resistance to corrosion allow it to be used in the manufacture of medical devices, kitchen equipment, and in structural applications that are exposed to different kinds of atmospheric conditions.

Bronze

Basically, an alloy of copper, to which small additions of tin, aluminum, and nickel may be made, bronze variable thermal conductivity usually lies in the range 50 to 120 W/mK.

Its thermal properties make it effective for uses that require a combination of a moderate amount of thermal insulation with high mechanical strength, such as bearings, bushings, and sculptures.

Heat Transfer Control on PCBs

Application of low thermal conductivity metals in heat transfer management in PCB applications has been beneficial. With the increased sophistication of electronics, thereby increasing their power density and miniaturization, the effectiveness of thermal management becomes more critical to sustain system reliability and performance. How low thermal conductivity metals fit into that includes:

Thermal Insulation:

These metals help maintain the temperature stability within sensitive components by avoiding overheating and hence ensuring consistent operation.

Since they provide a thermal barrier, they keep elements that could cause extremely high temperatures away from more heat-sensitive elements, which helps protect the integrity of the system.

Energy Efficiency:

Minimizing excess heat loss makes it energy efficient, so electronic appliances work better and can eventually prolong battery life in portable devices.

A constant internal temperature eliminates the need for extra cooling mechanisms, thereby saving material and design costs.

Low Thermal Conductivity vs. Heat-Conductive Metals in Other Applications

While this low thermal conductivity is useful for certain situations, there are many more uses where high thermal conductivity metals are in extreme demand for the facilitation of the dissipation of heat:

Heat Exchangers:

Copper, well known for its particularly high thermal conductivity, is highly utilized in transferring heat in systems such as car radiators and air conditioning units.

The aluminum alloy represents conductivity versus weight tradeoff in the aerospace arena.

Heat Sinks:

The heatsink serves a very important role in the electronic equipment in dissipating unwanted heat from the most sensitive components of the electronic devices, including processors and LEDs. The materials normally used are metals that have high thermal conductivity but with low mass, just like the case of aluminum alloy.

In the case of PCBs, this means that the highly thermally conductive metals will make sure that excessive heat is taken away as quickly as possible, improving performance and prolonging the life of such devices.

Cookware:

Cookware will make use of metals like copper, which have high thermal conductivity, to uniformly distribute heat for effective cooking.

This strong thermal response is actually the basis for better control over the cooking environment and energy economy.

Specific Heat Capacity

Aside from thermal conductivity, another most important attribute in metals is the specific heat capacity, which is the energy required for raising the temperature of unit mass by one degree centigrade. Metals with low specific heat reach operating temperatures in extremely short times, a fact that is advantageous in heat exchangers but less in favor in PCBs, which rely on stability. High specific heat metals offer gradual changes in temperature, and in this case, maintaining the thermal stability of electronic components is easier.

Benefits of Low Thermal Conductivity Metals

The advantage of low thermal conductivity metals is that they offer a host of advantages, which includes:

Material Stability: Under fluctuating thermal conditions, these metals tend to retain their structural integrity and, therefore found to be durable and reliable for long-term applications.

Application Versatility: They find applications not only in the construction of PCBs but also in architectural designs and industrial machinery, where heat stability is considered important.

Cost-effectiveness: This could decrease the demand for complicated cooling systems, hence reducing the general cost of production and enhancing the efficiency of the device.

Applying the thermal behaviors of metals is the key to realizing the most from PCB design and other engineering applications. At PCBX, our emphasis on integrating the best material ensures the creation of systems that meet not only the performance expectations but also excel in reliability and efficiency. Low thermal conductivity metals, such as stainless steel and bronze, have great potential in applications where retention of heat is as important as dissipation. And it would be possible for the engineer, by the correct selection of metal considering specific thermal and mechanical requirements, to create innovative solutions which will enhance the capability and longevity of their products in today's technology-driven world.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Black FR4 PCBs offer aesthetic and functional benefits, including light blocking, heat dissipation, and enhanced signal performance, suitable for electronics.

PCBs (Printed Circuit Boards) are fundamental in electronics, composed of multiple layers like silkscreen, soldermask, copper, and substrate, chosen for specific electrical functions.

Aluminum PCBs are widely used electronic boards with comparatively better heat dissipation properties. The aluminum core cools down the components of the product, thereby improving its performance. These are eco-friendly, light, and strong PCBs and hence appropriate to be used in audio equipment, power supplies, and lighting products such as LED lighting.