Mobile Communication PCBs

PCBs are crucial for mobile communications, enabling rapid, reliable data transfer. Innovations in PCB tech will support future networks like 5G and IoT.

In today's hyper-connected world, where instant communication is no longer a luxury but a given, the technology behind such connectivity hums silently yet indispensably at the heart of every device: the Printed Circuit Board. Especially in the field of mobile communications, the PCBs have grown with technology to become the critical infrastructure that underpins our everyday connectivity. This article explores the evolution, importance, and future of PCBs in mobile communications and how they have kept-and will continue to keep-us connected.

From Switchboards to Advanced PCBs

From switchboards to the rudimentary days of human-to-human connection through call management, it comes as no surprise that, with such turn of events, communication technology has undergone quite a transformation over the years. Thanks to PCBs, this evolution is bright; hence, the advancement from the primitive days of physical switchboards to even more advanced PCBs would not have shown just an evolution in technology but a miniaturization revolution of unseen levels.

Today, communication is nearly instantaneous through a maze of mobile towers, servers, and satellites. Advanced processing capability and reliability are thus behind the fast pace of communication brought about by PCBs in mobile communications. These are not pieces, but rather form the pivots that ensure the whole apparatus of communication works with no glitches.

Understanding Mobile Communication and PCBs

To fathom the contribution of PCBs to mobile communications, there is a need to understand what entails mobile communication. It merely describes data transmission over mobile devices wirelessly, without any physical cable or wire links. It includes devices, namely, mobile phones, via which data transmission occurs wirelessly across the cellular network. The need for such a rapid communication and ubiquitousity demands PCBs that are reliable and supportive of a series of components in which modern communication technology is incorporated.

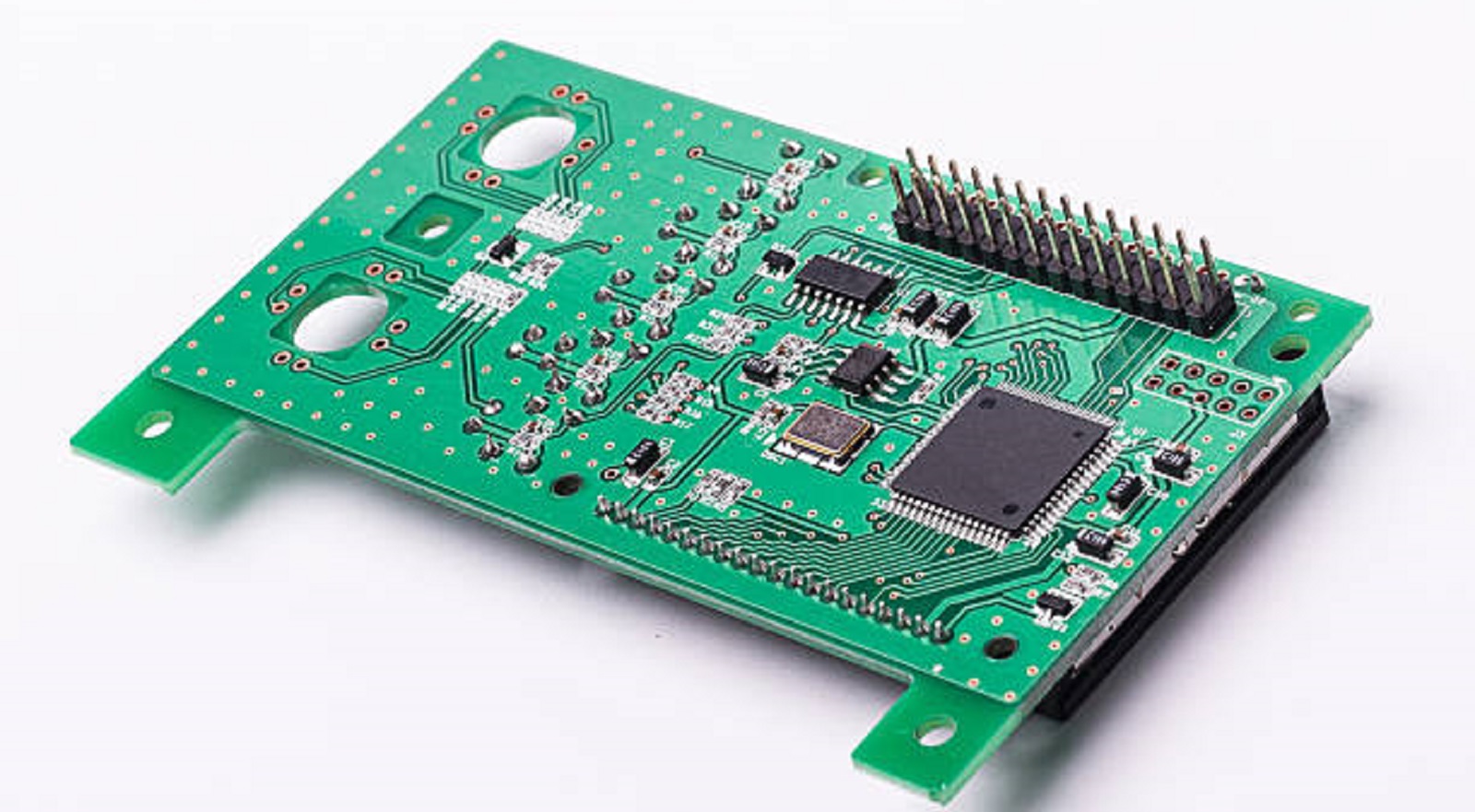

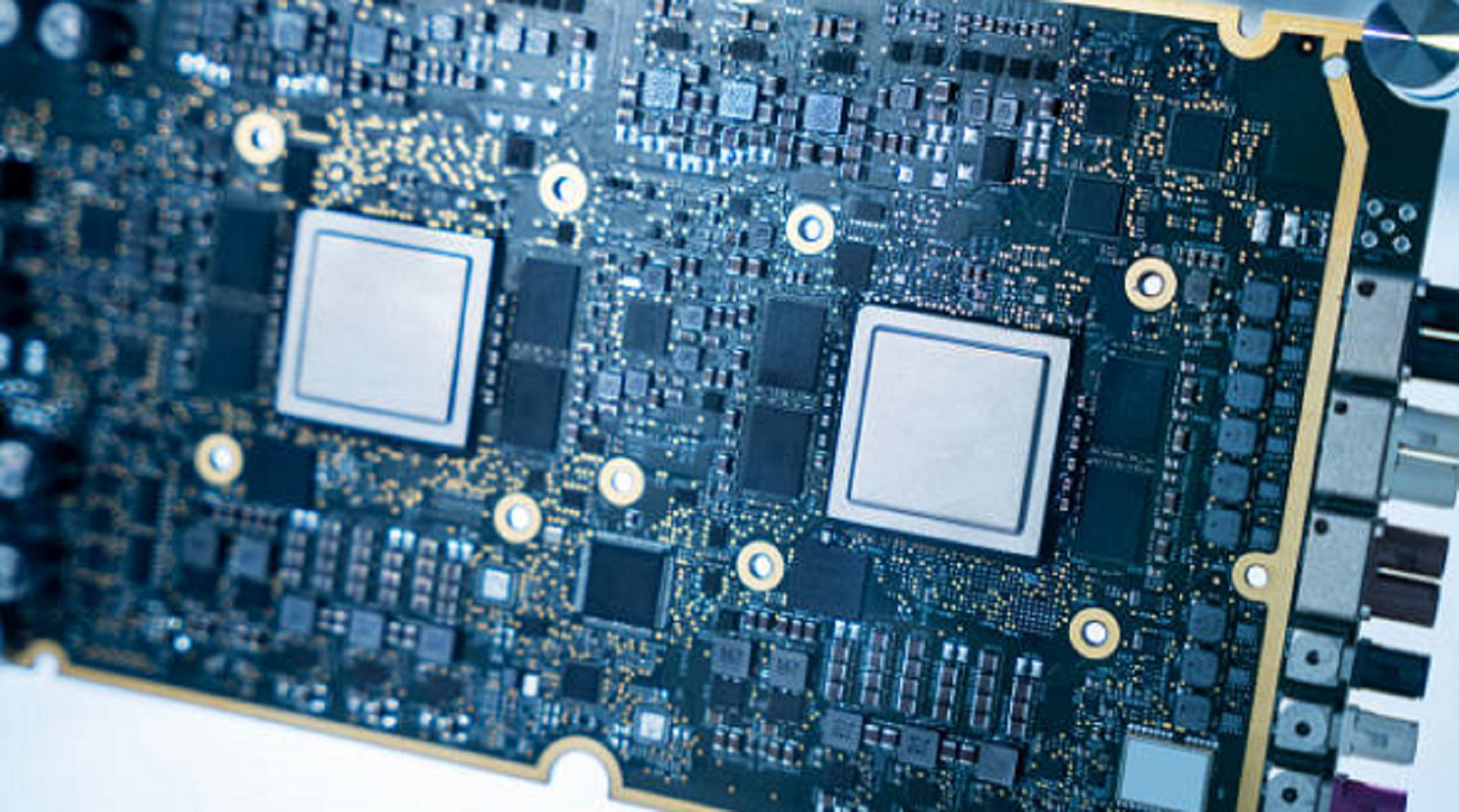

Mobile communications PCBs are designed for large processing volumes, signal integrity, and extreme packing density to accommodate the utmost number of devices in the smallest dimension possible. Each of these necessities is unique to this area and results in constant challenges in PCB designs and manufacturing processes.

Key Features of Mobile Communications PCBs

Miniaturization and Scalability: The miniaturization trend has heavily impacted PCB design. New PCBs need to fit within the ever-decreasing bounds of portable devices, managing ever-increasing data loads. This led toward multi-layered designs, high-density interconnects (HDI), and other advancements.

Material Selection: When PCBs are exposed to extreme temperatures or environments, material selection is quite important. The traditional FR-4 is used widely, though more resilient ones like polyimide and aluminum are becoming standard. This material offers a better thermal stability and is absolutely essential for conditions where the equipment is used, such as satellites or cell towers.

Signal Integrity: With the need for high-speed data transfer, signal integrity is a very important aspect. Engineers must design PCBs in such a way that interference and noise are kept to a minimum, which may distort signals. This requires careful trace routing and the use of differential pairs to ensure clean and reliable transmission of signals.

Flexibility and Shape Adaptation: As mobile devices and their applications have diversified, PCBs often need to fit into unconventional shapes and spaces, especially in aerospace and wearable technology. Thus, flexible PCBs from polyimide material will bend and twist to match up with those particular requirements without performance or durability issues.

Applications Across Telecommunications

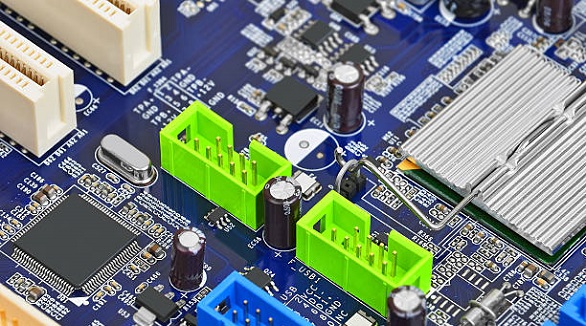

The diversity in the applications of mobile communication PCBs justifies such a relevance. They form an essential part of many systems ranging from PBX to VoIP equipment and video collaborations. They ensure connectivity both in the commercial and consumer markets. Moreover, they have pivotal roles within more complex systems of telecommunications, for example, satellites, routers with a high speed, and military communication systems.

These applications depict how PCBs can withstand entirely different functional demands while still providing high performance under various operating conditions. For example, in space application, where each component plays a role in the success of the mission, PCBs with superior heat and vibration resistance are essential.

Evolution and Future of Mobile Communication PCBs

From a heavy, cumbersome device in the 1970s to the sleek smartphones of today, PCB technology has moved in parallel with mobile phone evolution, allowing for a plethora of features, such as touchscreens, Wi-Fi connectivity, and processing units of unparalleled sophistication, to fit into these compact sizes.

As we advance to 5G and the Internet of Things (IoT), PCBs will become even more essential. These technologies require even more from PCBs in terms of processing power, signal integrity, and space efficiency. The future of telecommunications depends on continued innovations in PCB technology to support faster, more reliable networks and applications.

Challenges and Innovations Ahead

Despite their essential functions, there exist some major issues that PCBs in mobile communication face, some of which relate to EMI management, thermal management, and manufactural sustainability problems. Developments in such directions-for example, the development of eco-friendly materials and techniques-are considered highly important for future prospects in the industry.

But it gets even better because, with increased sophistication of mobile phones, the infusion of AI and machine learning on a PCB does promise a set of more intelligent, independent circuits that diagnose and optimize performance by themselves.

Printed Circuit Boards are the unsung heroes that enable modern mobile communications. They reflect the rapid progression of communication technology, standing as critical components that keep our world connected. As consumer demands and technological standards keep changing, firms like PCBX continue to take steps forward in harnessing the power of PCBs in order to sustain them well ahead of meeting future needs. Because the world increasingly relies on mobile communication technology, innovations and developments for PCBs are crucial for taking steps forward to establish this crucial infrastructure.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

High-frequency PCBs are crucial for fast, reliable tech, enhancing performance in telecoms, aerospace, and more with advanced materials and precise designs.

IoT and RFID integration revolutionizes device communication, improving data, asset, and operational management. PCBX supports these innovations amid challenges.

Designing PCBs for IoT demands innovation to tackle space, power, connectivity, and security challenges, ensuring robust, efficient, cost-effective devices that meet modern technological demands.