Overmolding Circuit Boards

Overmolding circuit boards enhances durability and functionality by protecting them from environmental damage, improving strength, aesthetics, and brand differentiation.

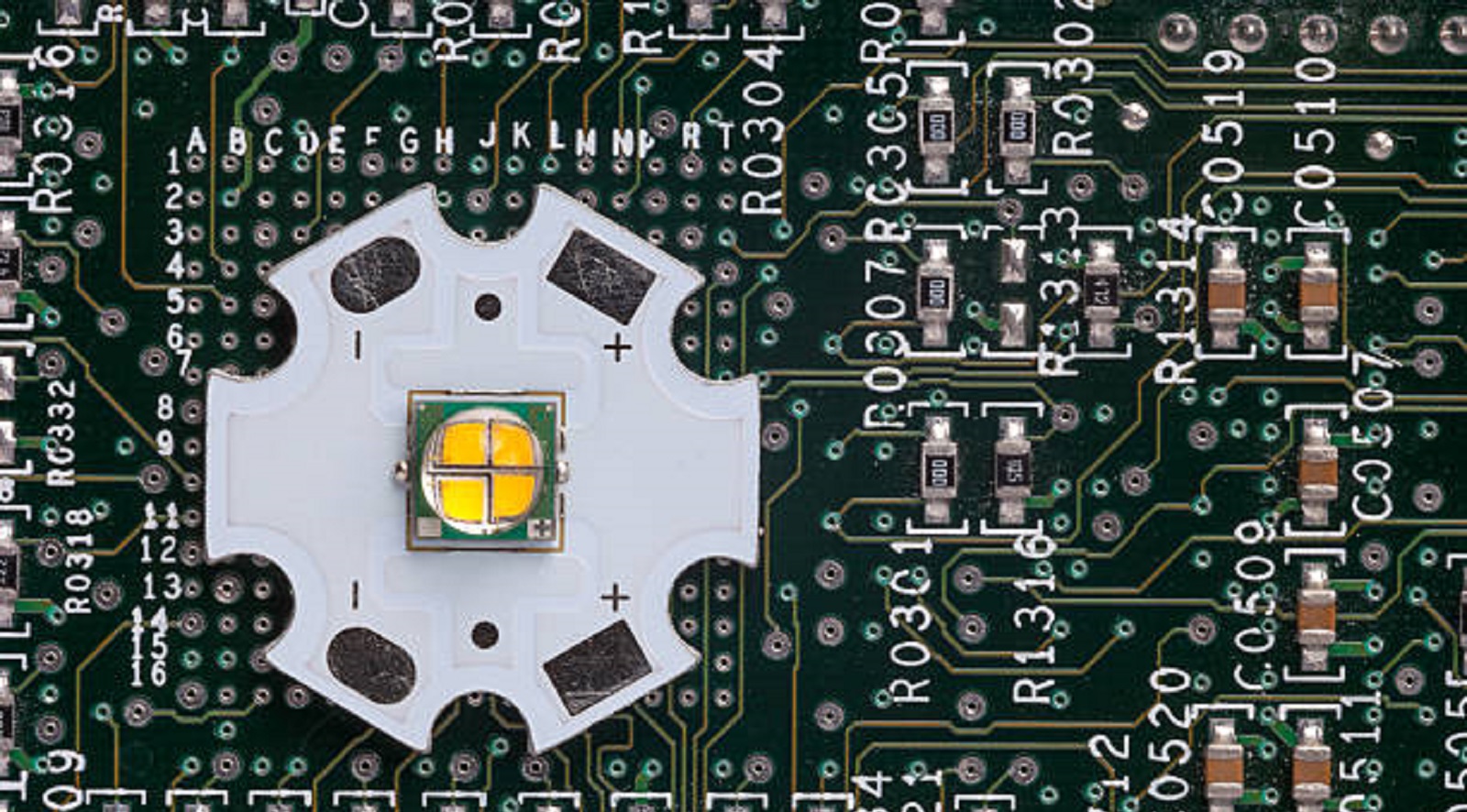

Overmolding of circuit boards is a new frontier of a process using protective materials to extend durability and functionality of a printed circuit board. Since most of the printed circuit boards are sensitive to the surrounding environmental conditions, overmolding offers a formidable method of protecting these electronic components without necessarily compromising their appeal. This article will take a closer look at what overmolding involves, the associated benefits, process, and issues related to implementing overmolding in PCB manufacturing.

Understanding PCBs and Their Vulnerability

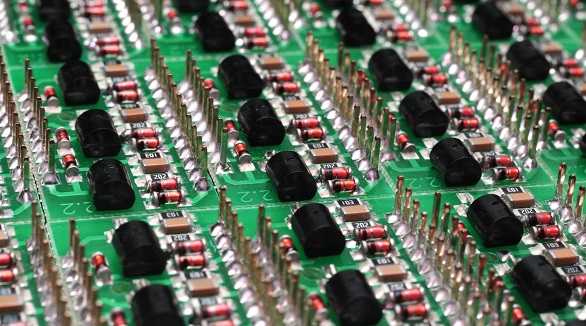

Printed Circuit Boards are the heart of modern electronics, carrying paths for electrical connections and integrations of various electronic elements. Traditionally, all these elements were connected with extensive wiring, which made production and maintenance very cumbersome. The invention of PCB technology allowed circuits to be printed on a substrate, thus simplifying manufacturing and allowing more compact designs.

However, these PCBs are susceptible to environmental conditions such as moisture, dust, chemicals, and even to mechanical shock affecting their functionality and durability. As a countermeasure, overmolding is a method that virtually covers the PCB, protecting it from harsh environmental conditions.

How Overmolding Works

Overmolding refers to the encapsulation of a PCB assembly by an injection molding process. There are primarily two ways in which overmolding can be done:

Direct Injection: The workpiece, or PCBA, is placed inside the mold, while the overmolding material (these days mostly thermoplastics or silicone) is directly injected over it. This technique allows flexibility in design, including customization options for colors and logos.

Cap Encapsulation: The basis of this method is placing a protective cap, like Lexan over the PCB then overmolding. The encapsulation provides a very strong barrier for the PCB, and additional protection is given by the overmolding process.

Each one of these methods is chosen with considerations regarding the level of protection that is desired, the number of production units, and aesthetic concerns.

Advantages of Overmolding Circuit Boards

Overmolding of circuit boards comes with a great deal of advantages, therefore making them more preferable in many industries:

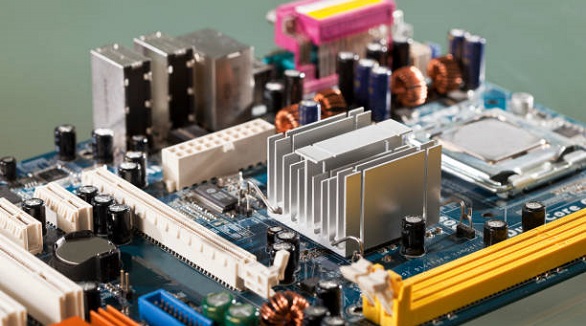

Enhanced Protection: The protection factor is probably one of the major reasons why overmolding is widely used. This is because durable material protects PCBs from moisture, dust, and physical impacts-which ultimately lessens the failure rates due to environmental factors.

Improved Mechanical Strength: Overmolded PCBs have higher resistances to flexural and tensile stresses; thus, they are best for high-traffic areas and equipment that is liable to wear and tear. Toughness and Resilience: The overmold acts like a line of defense against extreme temperature, abrasions, impacts, and other external forces that may come its way and which might destroy the encapsulated components.

Aesthetic Appeal: The end product is normally more aesthetically appealing when circuit boards are overmolded; the artistic factor combines well with functionality, therefore adding value in terms of consumer perception and selling capacity.

Brand Differentiation: Overmolding allows easy incorporation of branding aspects such as logos and product names that are helpful for product positioning at little cost. Additionally, variations in the angles of exit points or inclusions of attached components are possible with custom designs.

Corrosion Resistance: Overmolding offers good barriers to most corrosive elements like oil and saltwater, thus making them fit for harsh environments.

The Overmolding Process

The overmolding of circuit boards may be as simple or as complicated as the operating equipment and the materials of choice. The main steps involved in overmolding circuit boards include the following:

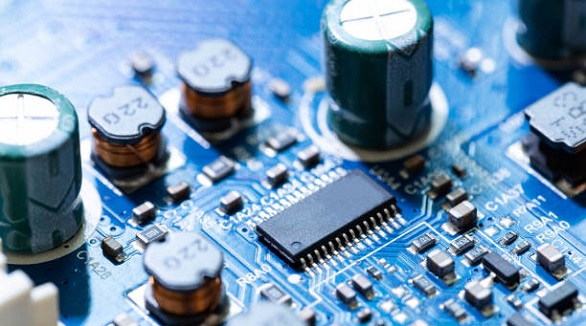

Material Selection: The selection of the right overmolding material is very important. The general choices are TPU and PVC, each with different properties concerning rigidity, flexibility, cost, and moisture resistance.

Injection Molding Equipment: Avail the appropriate injection molding machine. The machine has to apply the required tonnage in order to inject molten materials into the mold efficiently, and larger molds will require more pressure.

Filling and Injection: With the material chosen, the hopper of the molding machine is filled with the overmolding compound. Then, the injection screw will pump the heated material into the mold, cooling and solidifying around the PCB.

Cooling and Demolding: After cooling the overmolding material for a time to the point of solidification, open the mold, and carefully remove the finished overmolded PCB from it.

Quality Control: The final assembly is tested for electrical functionality, as well as other mechanical studies to ensure the product is according to industrial requirements.

How to Successfully Overmold

Overmolding entails putting into consideration a number of aspects, and when put into consideration it helps in achieving the best results:

Training and experience: Overmolding professionals should have technical know-how so that they don't encounter problems that will result in bad products or machinery breakdowns.

Cost-Benefit Analysis: While overmolding adds a layer of security and performance enhancement, this process has to be weighed against the cost implications. Investment in overmolding needs to be justified through the benefits accruing to the product in terms of reliability and marketability.

Testing and Validation: Overmolded PCBs must be thoroughly tested for environmental resistance, durability under expected operating conditions, etc.

Overmolding of circuit boards is a great advance in PCB technology both for protection and to improve performance or aesthetic qualities. With the increasing demand from consumers for long-lasting and reliable electronic gadgets, the overmolding process proves strong enough for such demands. The good news is that it's possible to fabricate long-lasting, high-quality overmolded circuit boards, provided that proper material selection is done, investment in suitable equipment is made, and best practices are applied throughout the process. For professional help in overmolding your PCB projects, do not hesitate to contact us at PCBX for expert guidance and services.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Burn-in boards are vital for testing semiconductor reliability, simulating stress to reveal defects, ensuring high-quality devices before mass production.

Carrier PCBs are crucial for data modulation, multiplexing, and network integration, supporting efficient and robust telecom infrastructures globally.

Amplifier PCBs enhance audio signals in devices like headphones and theater systems using components like transistors and capacitors for clear sound.