PCB Connectors

PCB connectors are crucial for reliable connections in electronics, enabling effective performance across various industries through careful selection and maintenance.

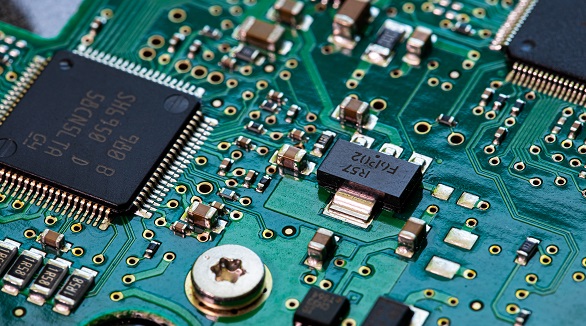

Among the sea of complexities that characterizes modern electronics, few components are tasked with bridging circuit complexity and functional viability of devices. One obvious class of components that come first to mind is Printed Circuit Board Connectors. Normally behind the scenes, they remain imperative for innumerable electronic gadgets to serve the purpose of establishing viable contact between circuit boards and parts thereof. From consumer electronics to highly advanced aerospace technology, the world owes it to PCB connectors for facilitating smooth operation in several working systems around the world.

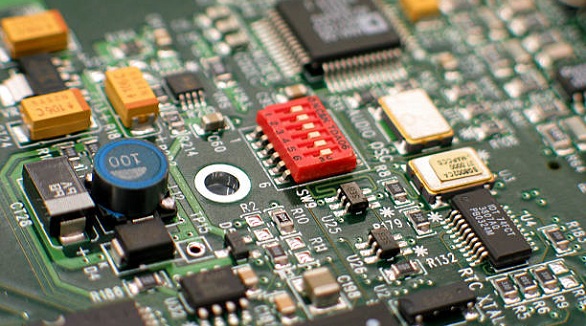

The important role of a PCB connector is to provide strong, reliable connections between several circuits. Whether for power transmission, data, or signal transmission from part of a system to another, this connector provides means of communication effectively in any environment. They are available in a wide variety of sizes and configurations, with design and construction possible to meet exact application requirements. One important consideration in the selection of PCB connectors is the pitch, or the spacing between pins and contacts, since this can greatly affect the design and functionality of the board.

Beyond pitch, other selection criteria include termination method, material specificity, coatings for added durability, and features such as locking mechanisms and keying to prevent misconnection. These all contribute to the right PCB connector increasing the electronic system's reliability and performance.

Types of PCB Connectors

Selecting an appropriate PCB connector requires awareness of the numerous types out there, each for a purpose:

Board-to-Board Connectors

Pin Header and Socket Connectors: Pin headers are male connectors that normally go with their female counterparts, sockets, in board-to-board or wire-to-board applications. They come in different configurations to ensure secure, reliable connections.

Mezzanine and Stacking Connectors: Used in applications requiring compact, high-density connections, these provide vertical or parallel connections between PCBs, ideal for data-intensive environments.

Card Edge Connectors: These connect PCBs by inserting a card edge into a slot. Examples of this are seen in computers for graphics cards and RAM modules.

Wire-to-Board Connectors

Crimp-Style Connectors: These are attached by crimping contact to the wire and are utilized in many applications requiring strong and reliable connections.

IDC Connectors: These provide fast, solderless connections and are utilized with ribbon cables in many applications.

Terminal Block Connectors: By using screw or spring mechanisms for clamping wires, enable easy insertion and removal, especially applicable in areas where multiple connections are required.

Specialized Connectors

FFC/FPC Connectors: These are flexible and provide a low profile, which is excellent for space-restricted applications in devices like laptops and mobile electronics.

USB, HDMI, and PCIE Connectors: These are crucial in today's world of digital connectivity. They allow the passage of data and power necessary for computing and networking equipment.

RF and Coaxial Connectors: Such as SMA and BNC, they find vital applications in high-frequency areas of RF and microwave systems.

The various types of connectors fulfill different purposes; their selection depends greatly upon the type of application. In deciding this, space, the required rate of data transfer, and conditions of the environment should be put into consideration to ensure best performance.

Key Features and Installation Practices

When choosing a PCB connector, pitch and size are important parameters that influence not only PCB design but also overall electrical and mechanical efficiency in the system. Smaller pitches provide more pin counts in smaller spaces, which may make it more difficult to manufacture; larger pitches are easier to produce and mate. The size of the connector is also controlled by space limitations and/or performance attributes desired.

Proper installation and maintenance are quite important in ensuring the reliability of PCB connectors. The manufacturers provide datasheets containing guidelines that outline the best practices for installation, which include pad layout on PCB, soldering time, and temperature. Polarization and keying features on installation ensure proper orientation that prevents damage and maintains integrity.

Routine maintenance includes periodic checking of the tightness of connections, cleaning to remove dust or other debris. Check for damage, such as housing breaks or pin bends, and corrosion in harsh environments, which can be prevented with protective coatings or materials.

Applications Across Diverse Industries

Some of the most important applications of PCB connectors can be found in:

Consumer Electronics: They are used in smartphones, tabs, and laptops to connect different components such as displays and batteries for continuous functioning.

Industrial Control Systems: They are used in programmable logic controllers and motor control systems, connecting sensors and actuators for effective operation.

Medical Devices: Connectors in medical equipment provide accurate, reliable connections critical to patient monitoring and diagnosis.

Automotive Applications: These connectors are essential in vehicle systems, ranging from infotainment set-ups to engine control units, for smooth functioning.

Aerospace and Defense: They are critical in avionics and satellite systems, providing secure connections under extreme conditions.

Telecommunications and Renewable Energy: The connectors in these fields ensure that the power and data transfer is effective to keep the network systems and green technologies running.

More than just physical links between electronic parts, PCB connectors are an essential part of the design and functionality of modern electronic systems. Careful selection and maintenance of them are quite necessary for achieving optimal performance of a device. In practice, good installation is the guarantee of effective work for these connectors over time. Being a leading player in this segment, PCBX emphasizes that understanding and applying advanced connector solutions plays an important role in enriching the functionalities of today's modern electronics. As such, with the basics of PCB connectors, we keep the pledge to ignite innovations and connect the ever-electrifying world.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

DIP switches, cost-effective and manual, enable easy configuration of device modes, offering flexibility and simplicity for various electronic applications.

Routine inspections and proper maintenance of capacitors and resistors in PCBs reduce failures, prolong device lifespan, and lower maintenance costs.

SMT assembly streamlines electronics manufacturing with compact, reliable designs using precise equipment, meeting high-density demands and international standards.