PCB Controller

PCB controllers are essential in modern devices, managing power, data, and operations across various applications, from gadgets to industrial systems.

In today's technology-based world, the use of PCB controllers is one of the necessary items and an integral component in any device used around us. These controllers take on the role of 'brain' for the devices, and their functions start from personalized gadgets to intricate industrial machinery. In this all-inclusive article, learn about PCB controllers, what they are, why they are essential, how the design goes, material selections, and uses of these control systems to select the correct one for your intended application.

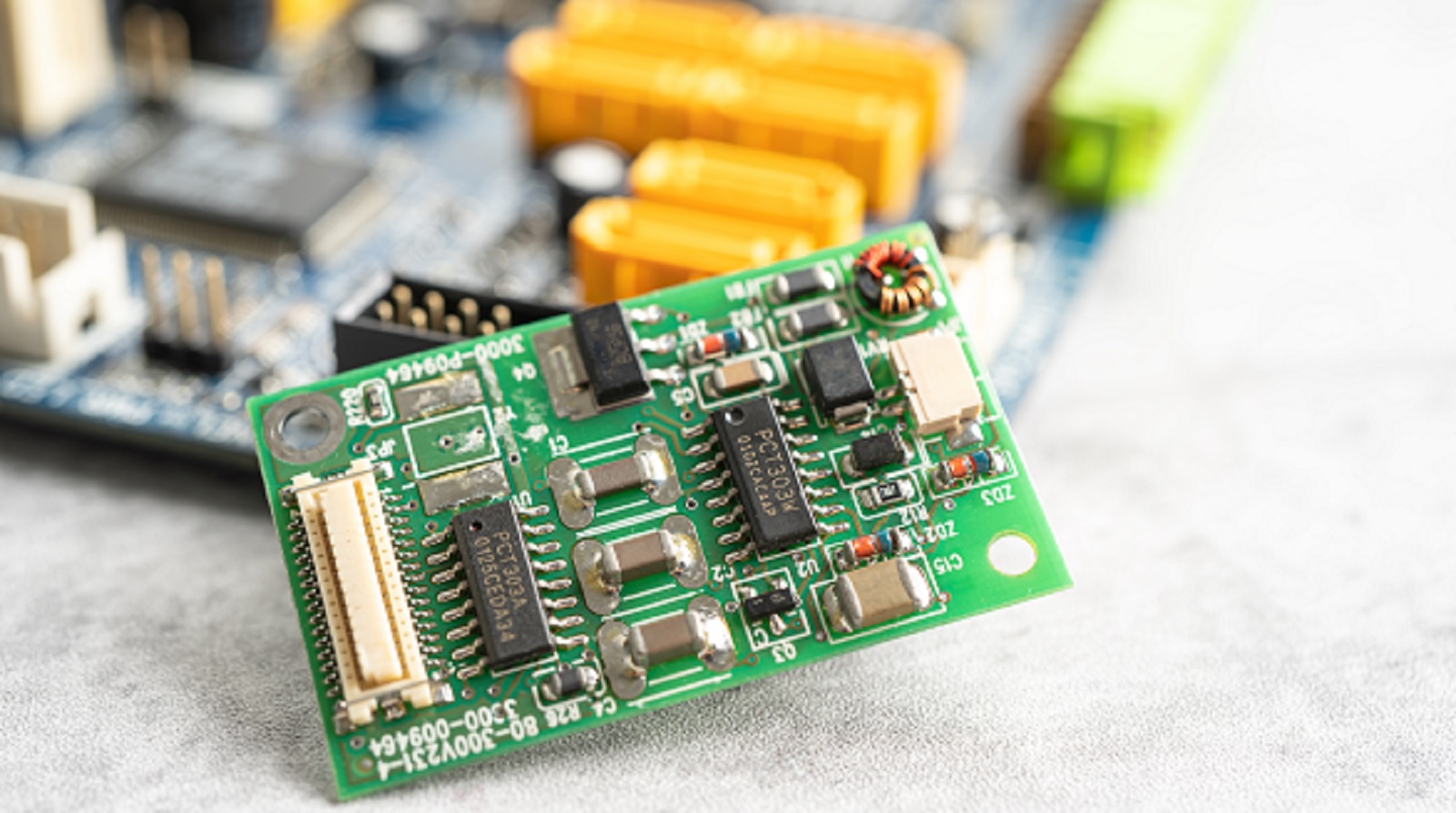

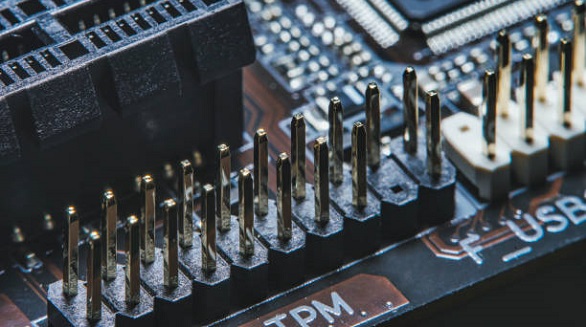

A PCB controller is an integrated circuit that is mounted on a printed circuit board for managing and controlling the working of different devices. It generally includes a microcontroller, I/O interfaces, and power circuitry, which ensure that the functions of data acquisition, signal processing, and power management are performed without any malfunction. It manages the timing, sequencing, and control functions that are required for the proper working of a PCB.

Main Components of a PCB Controller

MCU: The central processing unit that executes code and controls the functions of the device.

Memory: Both volatile and non-volatile memories are crucial in storing operational data, program instructions, and user settings.

Input/Output Interfaces: These ports provide a means of communication with other components and peripherals, supporting protocols such as UART, SPI, and I2C.

Power Management Circuits: These ensure that the controller operates efficiently under varying power conditions, which is crucial for reliability.

Designing a PCB Controller

Designing a successful PCB controller involves several stages, which require careful planning and precise execution.

Identify Requirements

Begin by establishing the controller's purpose, the type of application it will serve, and the technical specifications that it must meet. This informs all subsequent design decisions.

Microcontroller Selection

Choosing the right microcontroller involves considering processing power, memory capacity, interface support, and compatibility with the intended application.

PCB Layout and Sizing

The physical layout shall be designed to avoid signal interference and optimize thermal management. This involves defining the number of layers corresponding to the board complexity or component's pin pitch.

Component Selection

Selection will depend on functionality, price, power consumption, and if they are available. Higher-level applications may require varied components selected for the purpose they are needed to operate.

Prototype and Testing

Prototyping involves fabricating a small batch to test for performance and reliability, ensuring the design meets all specified requirements before mass production.

Materials Used in PCB Controllers

The type of material used in making PCB controllers is very important, which depends on the purpose of being served:

Copper: It is highly conductive and strong and so is mainly used.

Gold: Offers superior conductivity and is used in applications requiring high reliability, albeit at a higher cost.

Aluminum Alloys: Cheaper but less durable, applicable for applications with various performances.

Material selection can also be affected by installation environments, such as inside a computer or external applications, and the requirements for protection against static electricity or environmental conditions.

Functions and Applications of PCB Controllers

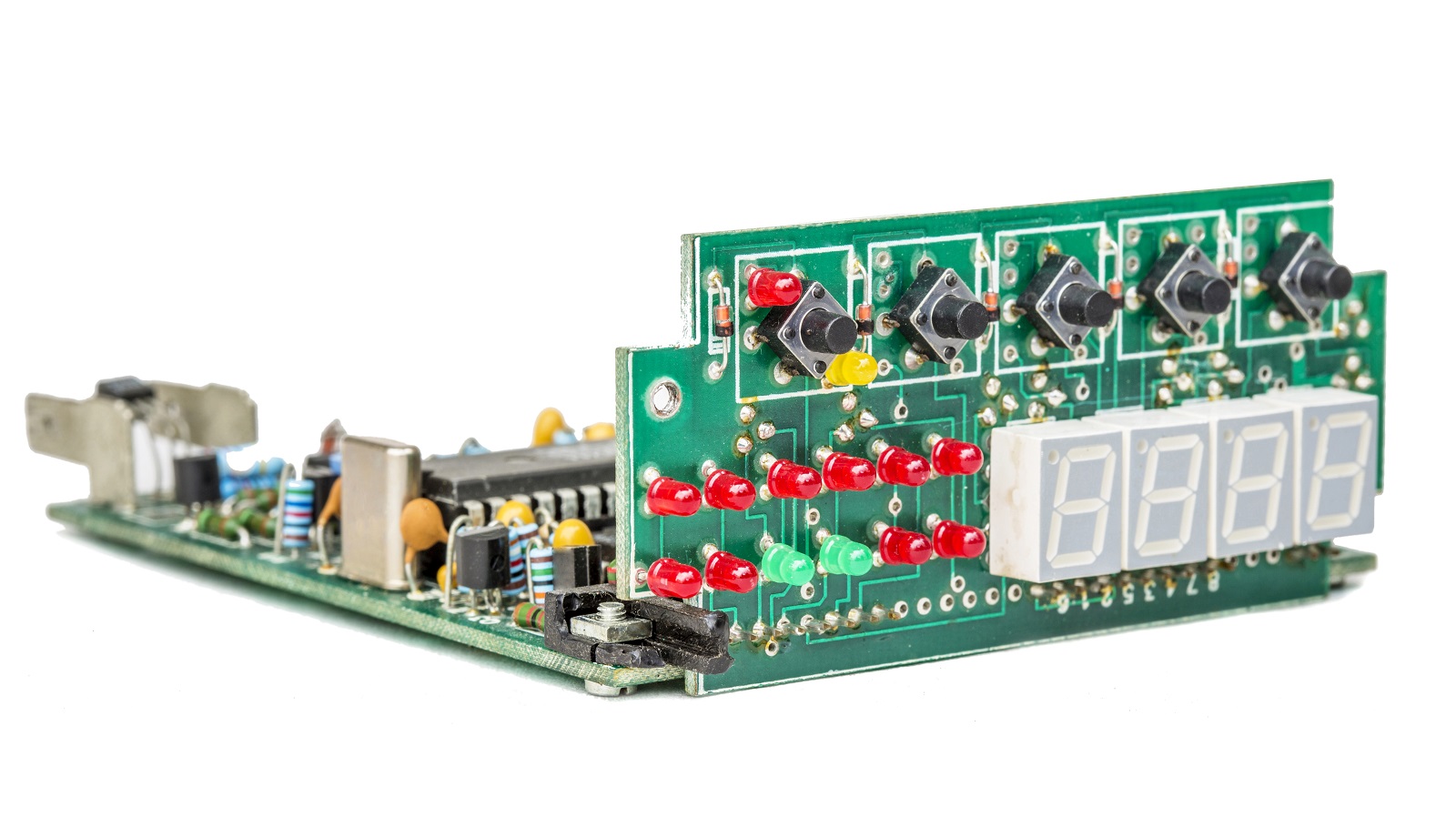

Functions

PCB controllers govern the operation of devices by managing inputs and outputs, power consumption, data flow, and operating temperatures within safe limits. They also deal with timing and configuration, which are very important in maintaining efficiency.

Applications

Consumer Electronics: Controllers in smartphones and tablets handle multimedia processing and connectivity.

Industrial Equipment: In manufacturing, PCB controllers drive automation and control machinery to provide precision and efficiency.

Medical Equipment: They monitor vital signs and manage device operations, ensuring accuracy and reliability.

Automotive Systems: Controllers manage functions such as engine performance and infotainment, contributing to advanced automotive technology.

Security and Robotics: Used in systems that require rapid processing and reliable operations.

Best Practices for PCB Controller Design

For optimal design and maintenance:

Modular designs facilitate easier upgrades and repairs by separating components into distinct sections, such as MCU and I/O modules.

Lay solid connectivity, ensure sufficient voltage supply, and manage every schematic block with advanced software meant for PCB design.

Today's modern electronics are founded upon and derive the much-needed intelligence or coordination through PCB controllers that have come into use through several applications. With total insight into design considerations, material requirements, and what their functional roles are in electronic assemblies, engineers successfully apply them to advance technological steps, making life instruments that humans use daily simpler and easier. In determining the proper controller for use, power, memory, compatibility, cost, and ease of use must strike the proper balance, ultimately performing for high reliability in all their applications.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

PCB connectors are crucial for reliable connections in electronics, enabling effective performance across various industries through careful selection and maintenance.

PCB pins enable connectivity in electronics, coming in types like through-hole and surface-mount, for signal transfer, power distribution, and modularity.

PCB headers, essential for PCB connectivity, feature varied pin types, are used in numerous applications, and aid in both learning and tech development.