PCB Embedded Components

Embedded PCB components enhance space efficiency, reliability, and performance, driving innovation in compact electronics for consumer, automotive, and medical applications.

The development of electronics has been in the direction of the ever-pressing need for devices to be more compact, efficient, and powerful. A very important innovation catalyzing this trend has been the integration of PCB-embedded components. The main focus in this paper will be benefits, applications of embedded system PCBs, and perspectives on what it holds for the future of electronic design.

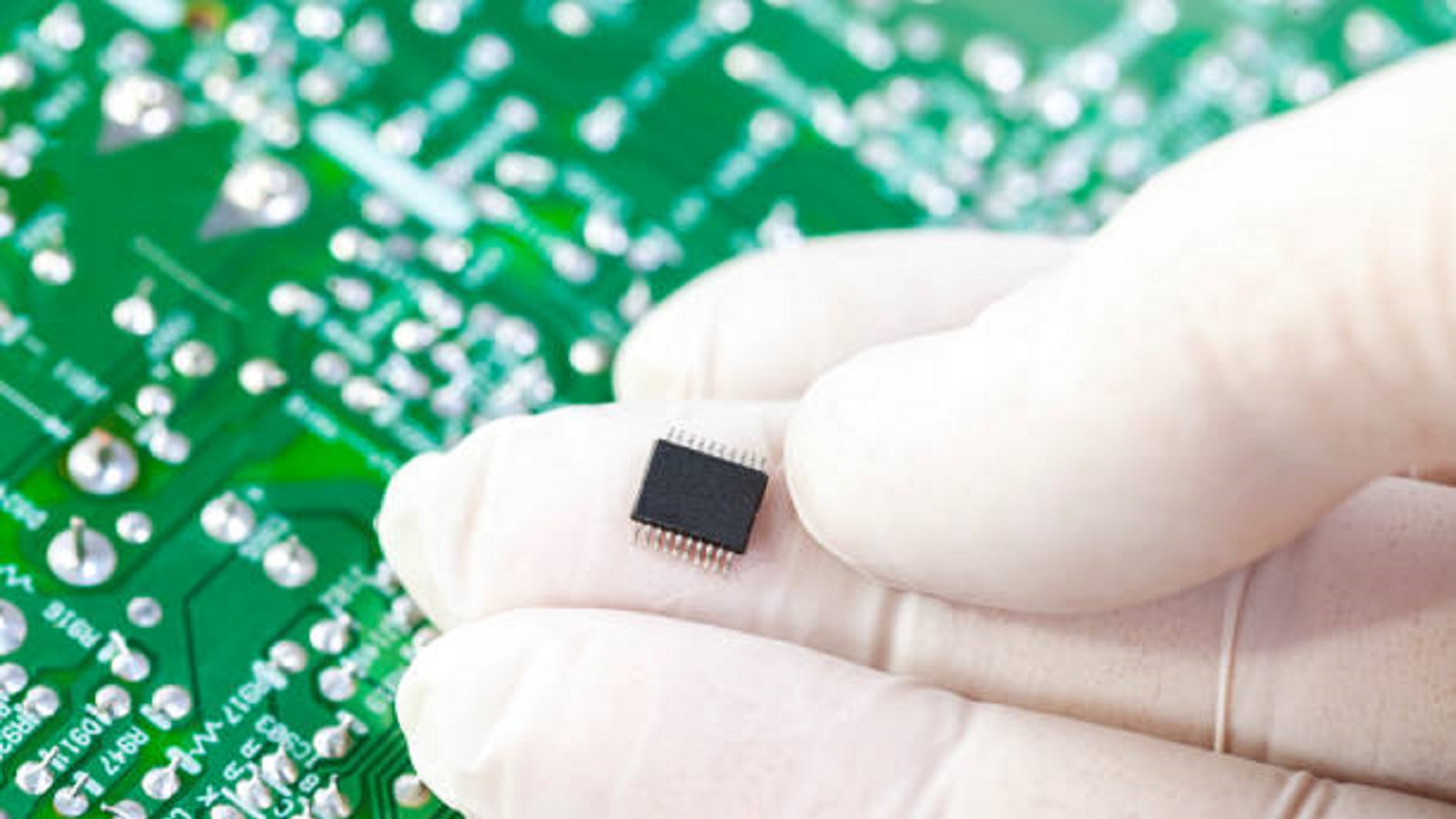

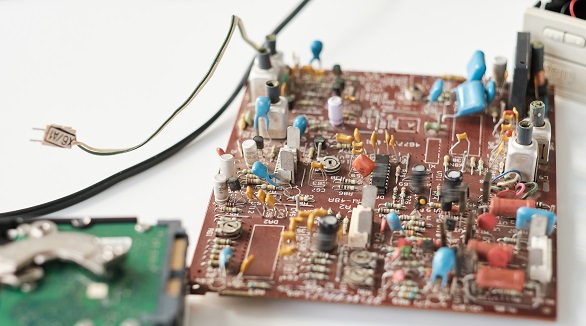

Embedded components in PCBs involve the embedding of active and passive electronic components, such as resistors and capacitors, and even microprocessors, directly in the layers of a PCB. Instead of the conventional mounting on the surface, embedded technology puts elements inside the board for big advantages in design efficiency and space.

Advantages of Embedded Components

The integration of embedded components within PCBs comes with quite a number of major benefits:

Space Efficiency

Embedding components in the board dramatically reduces the board space that is needed. It allows designers to make smaller devices or add more functionality to an existing product, which is highly important in consumer electronics where compactness is a priority.

Improved Electrical Performance

Embedded components reduce inductance and resistance by shortening the interconnections, hence improving signal integrity and increasing data transmission speeds. This performance boost is particularly important in high-frequency applications where efficiency and precision are critical.

Improved Reliability

Embedding components enhances the mechanical integrity and protects them from external environmental factors, hence making the devices more reliable and durable.

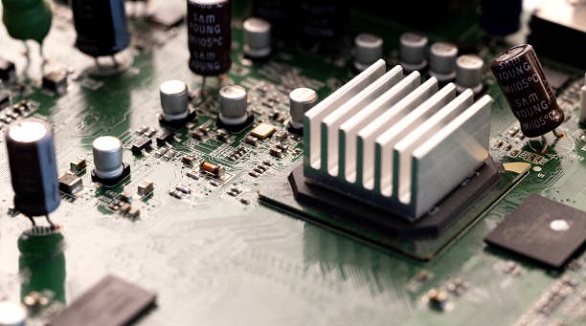

Effective Thermal Management

Embedded components have better heat dissipation throughout the board, reducing hot spots and improving the thermal stability of the device to maintain consistent performance and durability.

Role of Embedded Components in Embedded Systems

Embedded systems, designed to perform particular functions within more extensive systems, benefit from embedded components. Their narrowed approach to design provides efficiency and cost-effectiveness not possible with general-purpose computers.

Consumer Electronics

Streamlined, efficient electronics for smartphones and wearables are enabled by embedded components, which let them have advanced features in very small form factors.

Automotive and Industrial Applications

In automotive and industrial, embedded components help to make electronics robust and reliable for supporting the demanding environment, thereby enriching systems like infotainment and advanced driver assistance.

Medical Devices

Embedded technology allows the design and development of accurate, reliable medical instruments, including portable diagnostic devices and implantables, where performance and size are critical.

Design and Integration Process

Embedded component integration into PCBs is a complex design process:

Requirement Analysis and Specification

It involves an in-depth analysis of the product's requirements, thereby translating them into a highly detailed specification package.

Schematic Development

The designer creates a schematic where the identification of the microcontroller or microprocessor and other components required for the application takes place. In addition, embedded components in a PCB are strategically placed to achieve optimal performance.

PCB Layout

PCB layout is designed very carefully with embedded components to focus on manufacturability, reliability, and electrical performance.

Prototyping

Prototypes are manufactured to validate the designs through several iterations, based on design challenges and to ensure functionality.

Firmware Development

At this stage, firmware development in embedded systems is developed parallel to the hardware. Firmware is essentially stored in non-volatile memory and plays a vital role in the integrated management of all components in an embedded system.

Testing and Validation

After rigorous testing and validation, the PCB will be validated for functionality under various conditions before mass production.

Challenges and Considerations

While the benefits of embedded PCB components are substantial, challenges exist:

Manufacturing Complexity: Embedment requires precise processes, affecting initial production costs.

Design Complexity: Expertise in advanced PCB design and component integration is necessary.

Testing and Repair Difficulties: Embedded components can complicate testing and rework since they are not easily accessible.

The Future of Embedded Components in PCBs

With the advancement in technology and reduced production costs, embedded component integration in PCBs would, therefore, see broader application. The rise of the Internet of Things makes demands for smaller, wiser, and more powerful devices, thus placing the embedded component technology at a crucial position for the new era of innovation.

It's technology positioned to further bridge intelligent home, wearables, and robotics. With enabling performance at shrinking size, embedded components are a very valued tool for today's designer seeking to help fulfill emerging demands.

Embedded components in PCBs represent a quantum leap in electronics design, offering space efficiency, enhanced performance, and reliability. As they start to become more common, they will revolutionize what embedded systems can do and result in innovative and efficient electronic products in many industries. Designers need to embrace this evolution to stay at the leading edge of technological progress, pushing the boundaries of what is possible in electronics design.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Capacitive circuits store and release energy, stabilize voltage, filter signals, and manage power flow, making them vital for modern electronic systems.

Breadboards and protoboards are key prototyping tools in electronics. Breadboards allow for flexible, solderless circuit design, while protoboards provide durable, soldered connections for finalized designs.

Capacitors are crucial in circuits for storing energy. Testing methods include in-circuit and out-of-circuit using digital multimeters, ESR, and LCR meters. Proper testing ensures reliability and prevents malfunctions.