PCB Middle Tg vs. High Tg

Choosing the right Tg for PCBs balances cost and performance: High Tg suits high-temp reliability; middle Tg fits moderate conditions and budget needs.

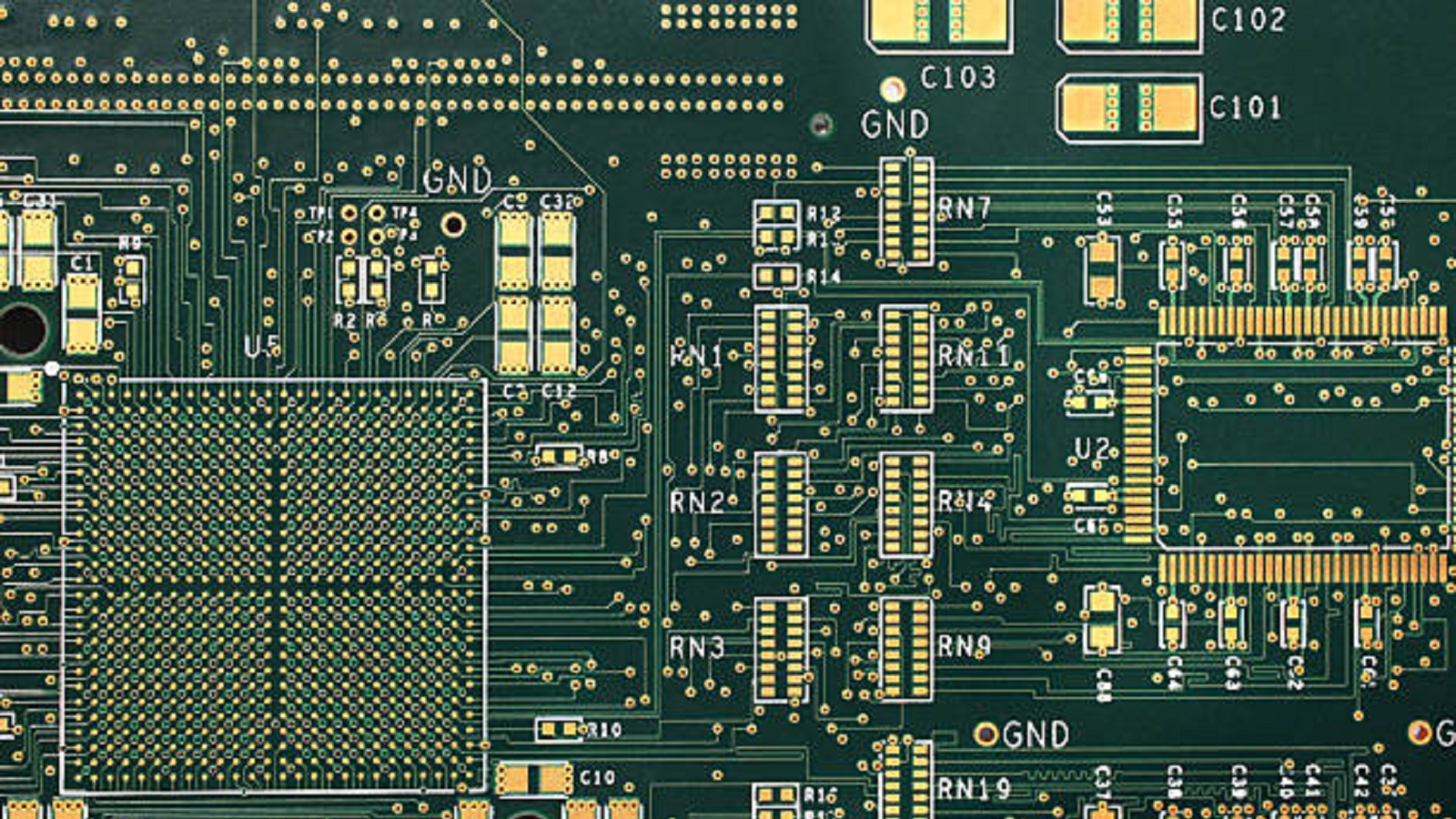

In the field of printed circuit boards, the Tg is one of the main factors that affect their thermal and mechanical performance. With increased requirements for electronic devices to serve under various and complicated conditions, the understanding of middle Tg versus high Tg PCBs becomes very necessary. Two varieties of PCBs are covered in this article: their characterizations, applications, and selection for suitable Tg to optimize performance in electronic devices.

The glass transition temperature describes the temperature at which the base material of a printed circuit board changes from a rigid and glassy state to one more flexible and rubber-like. This property is essential since it determines both operational reliability and structural integrity of the PCB assemblies, when exposed to thermal stress. PCBs that exceed their Tg will not melt, but their structures change and make the performances particularly worse, in cases where intense thermal cycling and high operating temperatures are involved. To be able to manage such mechanical stresses and avoid formation of micro-cracks in processes such as soldering, which is so crucial, choosing an appropriate Tg of a PCB becomes pretty important. This becomes particularly important with the introduction of the RoHS directive, which requires lead-free assembly and thus higher temperature demands during manufacturing.

Middle Tg vs. High Tg PCBs

Middle Tg PCBs

Middle Tg PCBs have Tg values typically within the range of 130°C to 150°C. These PCBs are perfect for conditions where there is a presence of moderate thermal and mechanical stresses.

Features

Sufficient Thermal Expansion: Handles consumer electronics' thermal needs where excessive temperatures are not a concern.

Cost-Effective: Cheaper than high Tg ones, thus applicable in budget-sensitive, low-to-moderate temperature applications.

Standard Material Composition: Normally made from FR-4, the standard material for most generic electronic applications.

Applications

Consumer electronics, such as smartphones, radios, and television systems.

Office and household appliances with consistent and moderate operating conditions.

General-purpose electronics, especially when the level of thermal cycling is low.

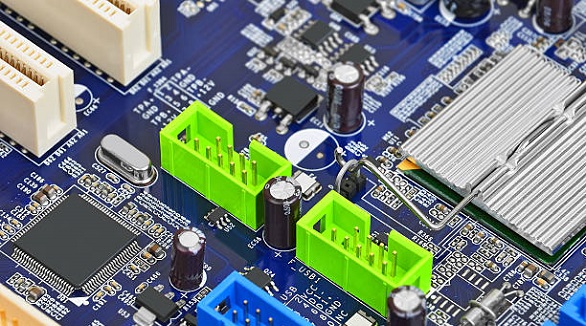

High Tg PCBs

High Tg PCBs are those whose Tg values are above 170°C. These PCBs are designed for high-temperature applications and provide very stable performance.

Features

Superior Thermal Stability: Excellent thermal stability helps to minimize defects like delamination, which could occur under high temperature continuously and degradation of property.

Enhanced Mechanical Strength: High mechanical strength gives better reliability when there is thermal or mechanical stress.

Resistance to Moisture and Chemicals: Anti-moisture and chemicals work well in the harsh environment for a long time.

Applications

Automotive Electronics: These work in fluctuating and high-temperature conditions.

Aerospace Systems: These bear extreme temperature variations, and high reliability is demanded.

Industrial Electronics: These are under intense electrical and environmental demands.

High-Performance Lighting: LEDs, for instance, need efficient heat management.

Considerations in Selecting Tg for PCBs

In the selection of middle Tg and high Tg PCBs, the following factors shall be considered:

Operating Temperature: Consider the temperature under which the PCB is to work. High Tg is necessary for both high-temperature and fluctuating conditions.

Cost and Material Factors: For projects where budget is a significant issue, mid-Tg materials are quite adequate, so long as they can meet the thermal requirements of the application.

Performance Requirements: Applications that require high frequency, high power, or critical reliability require high Tg PCBs.

Compliance Standards: RoHS compliance sometimes necessitates high Tg PCBs because of the higher temperatures used in the soldering process for lead-free procedures.

Advantages of High Tg PCBs

High Tg PCBs have certain advantages that meet the demands of rigorous applications:

High Temperature Resistance: Withstand extreme thermal stress without losing structural integrity.

Improved Mechanical Properties: Offer superior durability and reliability under stress.

High Power Density Support: Support more components with no overheating; important for modern, miniaturized electronic designs.

Middle Tg PCB Materials

The middle Tg PCBs find their major application where flexibility and cost-efficiency are of prime importance, mainly for applications not subjected to extreme thermal variations. They usually appear in consumer technology where there is a lot of moderate thermal expansion and mechanical stress.

Advantages:

Environmental Safety: Generally meet the basic requirements of environmental protection and have low emissions of hazardous substances.

Adequate Thermal Performance: Offer the necessary thermal stability, which is suitable for non-extreme applications.

Understanding the difference between medium Tg and high Tg PCBs is critical for ensuring that electrical devices fulfill performance and reliability requirements.High Tg PCBs are required for applications that require critical reliability and high temperatures, whilst midrange Tg PCBs are employed in everyday consumer and moderately demanding applications. Choosing the right Tg ensures that PCBs perform their purpose while balancing cost and specific application requirements. This, in turn, results in considerably stronger and more dependable electrical solutions that can thrive in the environment for which they were created. Recognizing this allows designers and engineers to make a number of decisions within the context of increasing technology while preserving the necessary efficiency and durability.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

High-frequency PCBs are crucial for fast, reliable tech, enhancing performance in telecoms, aerospace, and more with advanced materials and precise designs.

Gold recovery from circuit boards needs safety gear, precise dismantling, cleaning, etching, and filtering, crucial for safe e-waste recycling.

PCBs (Printed Circuit Boards) are fundamental in electronics, composed of multiple layers like silkscreen, soldermask, copper, and substrate, chosen for specific electrical functions.