PCB Slot

PCB slots, essential in design and performance, aid in electrical connection and heat dissipation. Both plated and non-plated types serve specific applications.

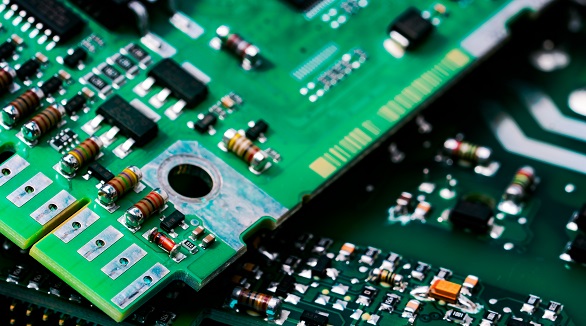

Within the intricately wired world of electronics, Printed Circuit Boards represent the foundational building blocks of complex devices. In keeping pace with the increased needs for smaller, more effective design units, the significance in every detail of a Printed Circuit Board design should also be focused on. This report concerns the essence of the usage of PCB slots, the varieties that may exist, their role within a PCB, and also the manner in which designers could apply them for increased functionality and reliability in electronics.

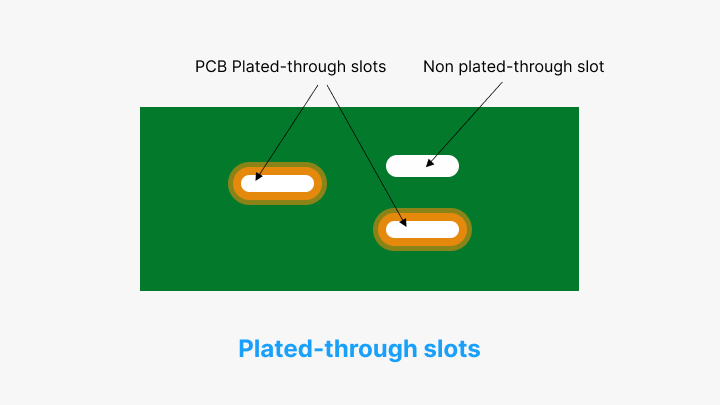

A slot in a PCB is not just an extended form of a hole in the board but rather a custom-made cut-out that may be too big or an unusually formed shape for ordinary drilling practices. Therefore, routing bits have to be used to form the slot. More so, slots can be classified as plated or non-plated and also have different purposes while at the architectural make-up of the PCB.

Types of PCB Slots

Plated Slots

Plated slots are outlined with their copper lining both on top and at the bottom. They are essential for the formation of electrical connections, mainly in components with square or rectangular leads, which do not align well with the normal round hole configuration.

Application of Plated Slots: These become absolutely necessary in through-hole component packaging, where space restriction forces an economical use of the area. For example, on blade-style connectors, plated slots allow for increasing pin counts to be used. Since space isn't a problem here, along with structural requirements, more scope for electrical interconnects is provided within multi-layer PCBs.

Design Implications: In size-constrained designs, plated slots offer board real estate savings while enabling effective component placement without losing any mechanical or electrical integrity.

Non-Plated Slots

On the other hand, non-plated slots do not have copper lining but instead serve mainly mechanical purposes. Non-plated slots are normally larger in size compared to the copper pad they are associated with, which helps in dissipating heat and also acts as structural separation wherever required.

Applications of Non-Plated Slots: Common in scenarios requiring mechanical separation, non-plated slots help to regulate thermal distribution across the board and prevent malfunction or deterioration due to overheating.

Designing PCB Slots

To design PCB slots requires a great deal of accuracy along with a proper and vivid understanding of the complete board layout. The Gerber mechanical layer plays an important role here, providing a proper representation of slot dimensions along with board profiling.

Slots Definition in Design Files: Designers should include slots using the Gerber mechanical layer by drawing the outline of the slots and taking care of clearance between copper and edges. Ambiguities must be avoided, and this may happen if slots are defined only in visible layers, for example, legend or copper layers. Adding a detailed README file to the design will help in communicating particular manufacturing instructions to the manufacturers for minimizing the chances of manufacturing discrepancies.

Using CAD Systems: Using CAD systems, designers can specify slots using X and Y dimensions corresponding to the slot's width and length. These software tools provide capabilities to simulate how slots will be fabricated, ensuring precision.

Eagle CAD Example: Slotted holes can be designed using dimension layers in Eagle CAD, even for complex matrices. The system ensures that the pad drill sizes will match up in the slot when creating the PCB outline to avoid fabrication errors.

Fabrication Techniques

When designs on a slot are finalized, the main interest would then shift to the available practical fabrication techniques of slots on PCBs; mainly by milling, especially in rigid boards, or through laser cutting in flexible circuits because their structure is thinner.

Slot Milling: Milling, as performed by NC grooving cutter bits similar to CNC machines, provides for accurate creation of slots. In such a process, inside corner radius is of critical concern and should have a minimum of 0.50mm to ensure that the slots can withstand mechanical stresses.

Minimum Slot Dimensions: For rigid-flex and flex circuits, the minimum slot width is usually 0.50mm. This feature needs to be carefully designed in order to maintain mechanical stability and ensure practical manufacturability.

Practical Applications and Considerations

The slots of a PCB are very useful in handling high-voltage isolation. With the milling of slots, designers introduce air gaps that prevent the risk of temporary electrical arcs, which may cause degradation in functionality over time. This is very important in high voltage applications where component-to-component isolation should be ensured to avoid short circuits.

Component-specific applications: Plated slots are advantageous for components with leads of other than a round shape. For instance, a rectangular connector is definitely served better by the footprint rather than by large, circular holes that may end up using too much room or not hold the leads of components properly.

Design Challenges: Conventional round holes work for square or round leads in most through-hole assemblies. Sometimes plated slots may be necessary due to some unusual shapes in component lead forms; in fact, they are critical for preventing defects, including voids in solder resulting from filling oversized cavities.

Ultimately, mastering PCB slot design and integration is integral in finding an optimal performance and reliability platform for modern electronics. Slots go well beyond being apertures within a circuit board; they contribute to the assembly, function, and life of such devices. By understanding the proper slot types-plated versus non-plated-designers can optimize both the mechanical and electrical performance of their PCBs. Indeed, as the electronics space has continued to evolve toward even greater complexity and smaller form factors, nuanced understanding in the realm of PCB slots has become increasingly important. This knowledge empowers the engineer and designer to innovate further with new electronic designs, bringing ideas into real technological progress.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

PCB plates enhance electronic devices' structure and function, crucial in keyboards for stability and connectivity. Materials and designs aid efficient decisions.

PCB copper plating is key for creating conductive traces that drive electronic circuits, offering benefits like conductivity, anti-corrosion, and cost-effectiveness. Plating methods include electroless and electrolytic.

Through-Hole Technology (THT) mounts electronic components by inserting their leads through pre-drilled PCB holes and soldering them. While durable and ideal for harsh conditions, THT is less space-efficient than SMT.