PCB Standoffs

PCB standoffs secure PCBs by spacing them, aiding in thermal management and vibration absorption. They're key for durability and adaptability in electronics.

In the field of electronic design and assembly, PCB standoffs, or otherwise called board spacers, are indispensable mechanical parts. They secure printed circuit boards in place and maintain necessary separation from other surfaces. These inconspicuous parts make great contributions to increasing durability, performance, and reliability in electronic devices across many industries.

Most PCB standoffs have a male and female end. The male end has threads for screwing into a tapped hole in an enclosure or chassis, while the female end has threads to accept a screw that secures the PCB. For spacing between the underside of the PCB and the mounting surface, it creates space. They are manufactured from materials such as nylon, brass, aluminum, and polycarbonate, chosen for their rigidity, durability, and insulating properties where required.

Key Functions and Properties

Secure Mounting: PCB standoffs avail a platform for mounting boards in the enclosure to keep components firmly attached.

Separation and insulation: Standoffs keep the PCB distanced from conductive surfaces to prevent possible short circuits and allow components on both sides of the board.

Thermal management: Spacing by standoffs promotes airflow and cooling beneath the PCB, which is critical to manage heat dissipation.

Absorption of Vibration: Shock absorption and vibration provide safety to sensitive components from mechanical stress.

Adjustable Height: The height can be changed by adding washers or extra spacers based on a specific design requirement.

Reusability: Sometimes they may be reusable, which enables modifications, iterations, and prototyping with much ease.

Standard Sizes and Materials

Standard sizes of standoffs are available to fit many applications, which are measured by thread diameter and length. They can be either male-female or female-female. The most common lengths are from 1/4" to 1", where metric sizes follow ISO standards. Compatible threads further mean they are compatible with conventional screws for convenience in procurement and use.

Material Types

Nylon: This is the most common material because it is economical and an insulator; thus, it will fit most applications.

Brass and Stainless Steel: Due to mechanical robustness, these materials are best for high-load environments and against corrosion.

Aluminum: It is also good for mechanical rigidity but needs insulation at its point of contact with the PCB for its prevention from electrical conductivity.

Polycarbonate and PEEK: High-end options that give a lot of strength and temperature resistance, although they cost higher.

Application of PCB Standoff

PCB standoffs have immense applications in all sections of the electronics industry:

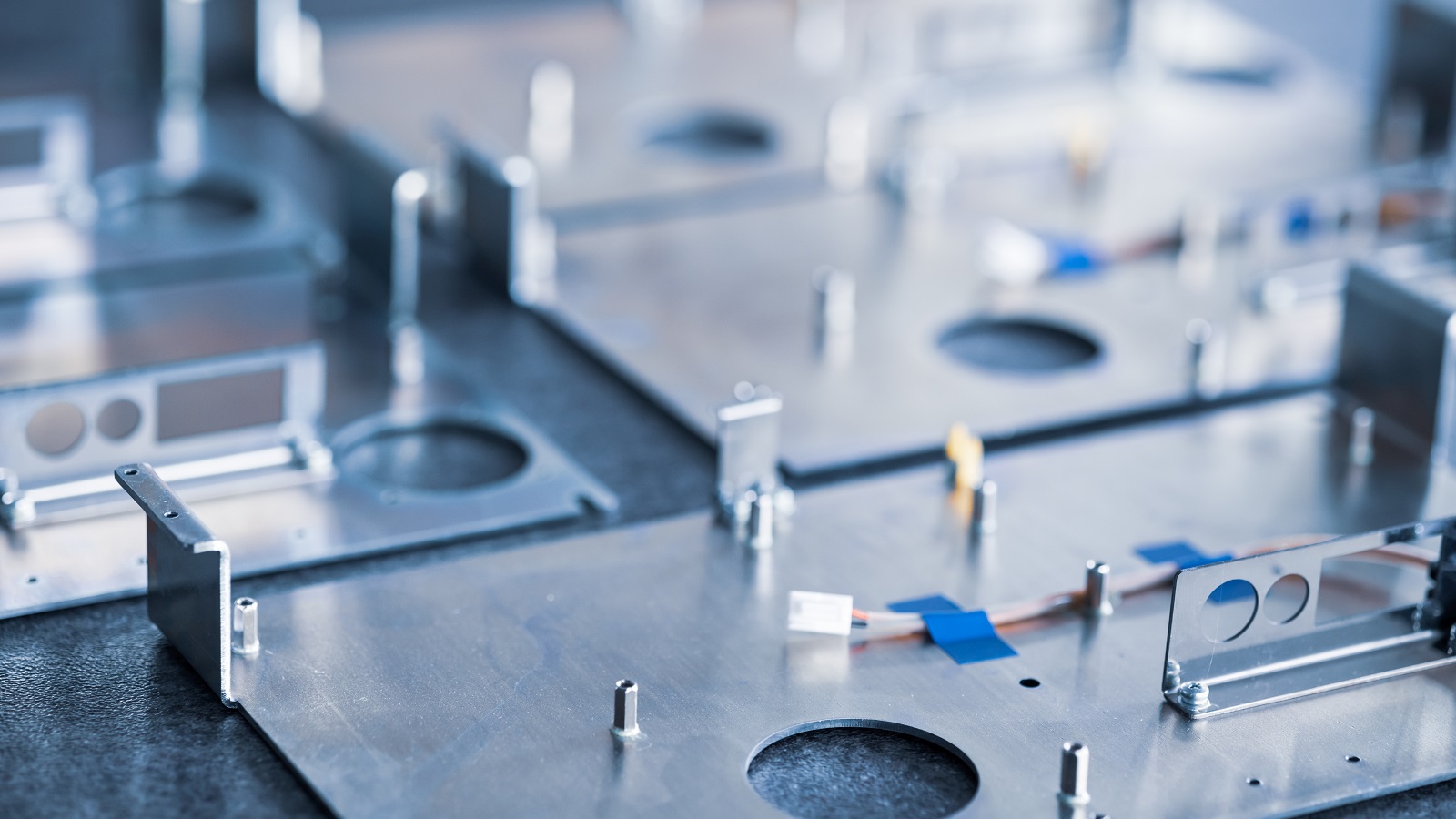

Electronic Enclosures: Mount PCBs in metal or plastic cases for insulation, with access to components underneath.

Stack Assemblies: Space apart stacked circuit boards to allow for inter-board connections.

Thermal Management: Create an air gap underneath the board for enhanced convection cooling, especially in high-temperature applications.

Prototyping and Development: The ease of installation and removal makes standoffs ideal during prototyping, where changes need to be made and tested quickly.

Test Fixtures and High-Frequency Circuits: Allow secure mounting in test setups, facilitating probe access and controlling RF impedance.

Installation and Best Practices

Proper installation of PCB standoffs is crucial to ensure optimal functionality. The process involves:

Marking and Drilling Holes: Identify precise standoff locations following placement guidelines and carefully drill to avoid board or component damage.

Securing Standoffs: Screw the male end into the mounting surface, ensuring adequate tightening without over-torqueing.

Aligning and Attaching Boards: Align PCB holes with standoffs and secure with screws, using washers as necessary to prevent damage.

Placement Guidelines

Edge and Corner Stability: Place standoffs near board edges and corners for increased stability.

Uniform Distribution: Distribute standoffs uniformly to avoid the concentration of stress for enduring structure.

Thermal and Accessibility Considerations: Allow standoffs not to obstruct airflow or block access to important test points and connectors.

Design and Customization

The design elements that may be added to a standoff include:

Flanged Heads and Locating Pinsa: For easy installation without standoff turning and to provide a given location.

Shoulder Washers and Jam Nuts: Prevent overtightening and keep the standoff at height.

Drive interfaces: Phillips or hex to ease high-volume production installations.

By understanding the roles of PCB standoffs and methods of implementation, the electronic designer can maximize designs for survivability and performance. As higher technological evolution concerning intricacy and miniaturization occurs with electronic devices, so will the importance of using standoffs to maintain structural integrity in the PCB for all manners of applications. Proper selection and application of these components are just underlining the importance of every detail in electronic design for the enhancement of reliability and efficiency of the device. The humble yet very necessary PCB standoff, with its supporting role so important, will continue to be a staple in the evolving landscape of electronics design.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Nets in PCB design ensure logical connections from schematics to layout, enabling connectivity checks, design validation, and optimized manufacturing processes.

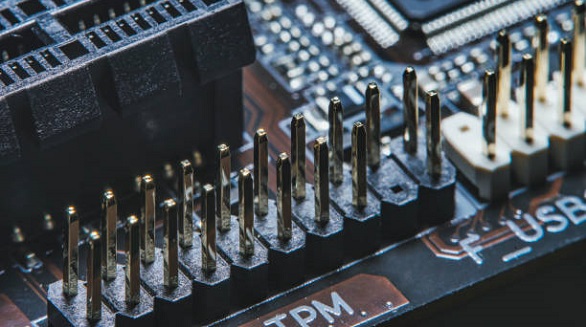

PCB headers, essential for PCB connectivity, feature varied pin types, are used in numerous applications, and aid in both learning and tech development.

Backdrill in PCBs removes stubs in vias to improve signal integrity and impedance control, crucial for high-frequency, multilayer boards. It’s vital in communication, servers, medical, and aerospace applications.