PCB Surface Finishes Introduction and Comparison

Selecting the right PCB surface finish, from options like HASL, ENIG, ENEPIG, and OSP, is crucial for preventing oxidation, ensuring solderability, and meeting reliability standards.

While ordering PCBs, one needs to decide upon the substrate material of the PCB, solder mask, silkscreen, surface finish, size and thickness of the board, the thickness of copper, blind and buried vias, through-hole plating, SMT, panels, tolerances, and any other specifications before your circuit boards are fabricated. Of these factors, the choice of surface finish is most important due to its large effect on the reliability of an electronic product. Since the copper layers on the PCBs are easily oxidized, this oxidation can seriously degrade soldering quality and hence the reliability or functionality of final products. The surface finish prevents the pads from oxidation, ensuring good solderability for electrical performance.

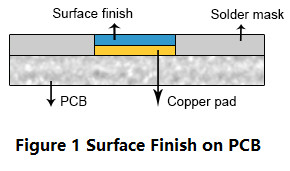

Surface finish, known as surface coating, is an important process between PCB manufacturing and circuit board assembly, offering dual functions in its processes: first the protection of exposed copper circuitry, and second solderability for component attachment. As seen in Figure 1, the surface finish is applied onto the outermost layer of the PCB on top of the copper, which functions like a protective "coat" for the copper.

Types of surface finish

There are mainly two big categories for surface finishes of a PCB: metallic and organic. Metallic finishes include HASL, ENIG/ENEPIG, Immersion Gold, and Immersion Tin, while OSP and Carbon Ink are under organic finishes.

HASL Hot Air Solder Leveling

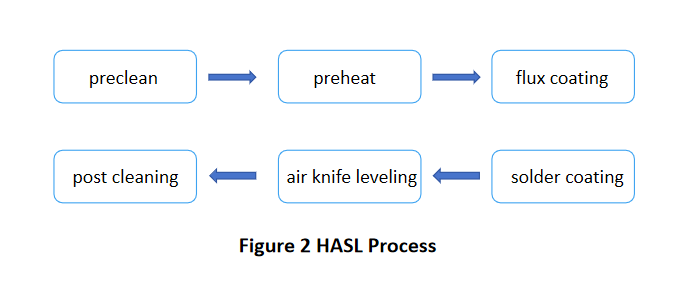

HASL is the conventional surface finish, which is always applied to PCBs. In this process, the board is submerged in a bath of molten solder; this flow completely covers all the exposed copper surfaces with solder. This excess solder is removed by passing the board through hot air knives as shown in Figure 2 below:

| Pros of HASL Surface Finish | Cons of HASL Surface Finish |

| • Excellent wetting during component soldering; • Copper corrosion avoided; | • Low planarity on vertical levelers leads HASL unacceptable for fine pitch components; • High thermal stress during process causes defects into circuit board; |

On account of concern for the protection of the environment, HASL itself has evolved into two variants: lead-based HASL and lead-free HASL. The lead-free version is compliant with RoHS regulations, first put in place by the EU.

ENIG and ENEPIG

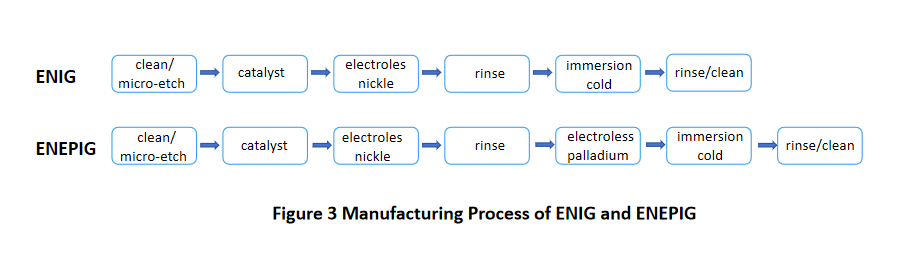

ENIG is an abbreviation for Electroless Nickel Immersion Gold. A coating of electroless nickel is put on the PCB, followed by a small layer of immersion gold to keep the nickel from oxidizing. ENEPIG stands for Electroless Nickel Electroless Palladium Immersion Gold, which means that in addition to what ENIG does, a palladium layer will be added to act as a barrier, preventing nickel from oxidizing and diffusing into the copper layer. While ENIG and ENEPIG provide far improved solderability to the other surface treatments, their prices are significantly higher. The varied processes for creating ENIG versus ENEPIG are diagrammed below in Figure 3:

The electroless nickel step is autocatalytic, a deposition of nickel onto the palladium-catalyzed copper surface. The reducing solution contains nickel ions, which must be maintained in specified concentrations, temperatures, and acid levels. During the Immersion Gold step, the gold adheres to the nickel-plated areas through molecular exchange and covers the nickel, protecting it until soldering, and control of the gold thickness within specified tolerances ensures the continued solderability of the nickel.

Both ENIG and ENEPIG have their pros and cons. On its part, ENIG has potential advantages from the fact that it has a flat surface to its fast application and high-temperature resistance. On the other side, ENEPIG brags of strength in withstanding reflow cycles and truly reliable wire bonding. Depending on the application imperatives, each finish has its chastened uses. ENIG is mainly geared toward lead-free soldering, SMT, and BGA packages. Oppositely, ENEPIG is applicable for rigorous processes like THT, SMT, BGA, wire bonding, and press-fit technologies.

ImAg (Immersion Silver)

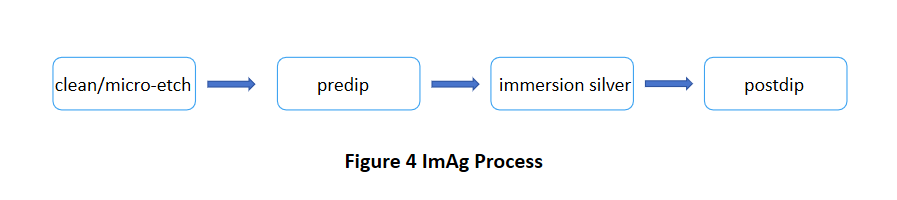

ImAg consists of a thin layer of immersion silver plating over copper traces. The standard procedure for making ImAg is as follows:

| Pros of ImAg Surface Finish | Cons of ImAg Surface Finish |

| • Planar surface; • Short, easy process cycle; • Inexpensive; • High conductivity; • Good for fine pitch product; • Copper/Tin solder joint; • Reworkable; • Not affect hole size ; | • Tarnish ; • Silver migration; • Planar micro voids; • Creep corrosion; ImAg offers a superior surface polish for soldering and testing. However, the main disadvantage is that it is prone to creep corrosion. |

ImSn—Immersion Tin

ImSn uses tin instead of silver, and one of the main advantages of this process is the very planar finish that it provides to the copper pads, which in turn makes it highly suitable for SMT applications. Another fast became the fact that ImSn offers a surface easily detectable by common AOI techniques used.

OSP: Organic Solderability Preservatives

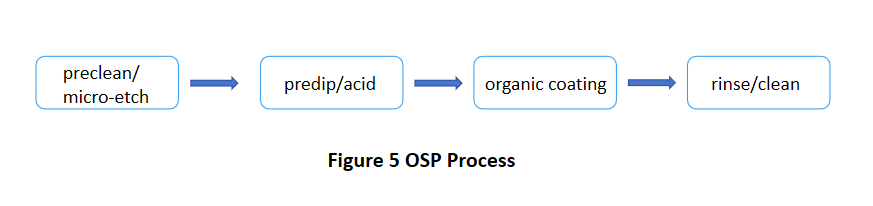

OSP belongs to the surface finishes using transparent organic material. The water-based organic compound can attach itself selectively onto copper, thus protecting it until soldering. The process of a typical OSP is as follows:

| Pros of OSP Surface Finish | Cons of OSP Surface Finish |

| • Flat/planar; • Short, easy process cycle ; • Inexpensive; • Reworkable ; • Not affect finished hole size; • Copper/Tin solder joint; | • Multiple reflows ; • Limited shelf life ; • Not conductive ; • Difficult to inspect; • Limited thermal cycles ; |

Summary

Each type of surface finish has different advantages and disadvantages. Selection should consider end-use application, performance requirements, cost, corrosion resistance, ICT capabilities, hole fill, and other applicable parameters. The more variables used to compare, the more accurate your selection will be.

Comparing Surface Finishes

- Cost: ImAg and OSP are the least expensive, with ENIG as the highest cost option.

- Corrosion Resistance: HASL and ImSn are at the top; ImAg is last on the list.

- ICT Capability: Essentially, all finishes are good, except OSP.

- Hole Fill: HASL and ENIG are excellent compared to other finishes.

Surface Finish Selection

Choosing an appropriate surface finish in the fabrication of printed circuit boards is very important for high process yields, low numbers of rework, low field failure rates, effective test capabilities, low scrap rates, and a lower cost. All significant factors related to assembly should be taken into consideration to ensure the final products are of a quality standard and performed accordingly.

Each occupant has different selection criteria. More often than not, the chosen surface finish meets particular requirements and convenience at the cost of quality, performance, and reliability of the PCB.

In light of the above descriptions of each type of surface finish, some attributes become very critical selection criteria. As one can tell from the form shown below, each of the types of surface finishes either has it or otherwise, giving a guideline for selecting the best option for the surface finish, considering the requirements and characteristics of your PCB products.

| Items | HASL | ENIG | ENEPIG | ImAg | ImSn | OSP |

| Cost sensitive product | √ | x | x | √ | √ | √ |

| High volume required | x | x | x | √ | √ | √ |

| Cosmetics of surface finish | √ | x | √ | x | √ | √ |

| Lead-free wave solder | √ | √ | √ | √ | x | x |

| Fine pitch components used | x | √ | √ | √ | √ | √ |

| Requirement of wire bonding to surface finish | x | √ | √ | √ | x | x |

| High yield ICT | √ | √ | √ | √ | √ | x |

| Lead-free shock/drop | √ | x | x | √ | √ | √ |

| Possibilities of corrosion failure | √ | √ | √ | x | √ | √ |

The ultimate in surface-finish selection should be to provide the optimal balance of the many functions. Each surface finish has its own list of pros and cons. Fortunately, there are techniques in engineering to help offset the negatives. Some examples are, to overcome the reduced wetting force of OSP, consider one or more of the following: improve the board solderability plating, alter wave solder alloys, or increase top-side preheat. It is all about taking every possible consideration to reach an optimum performance.

The growing importance of environmental issues in the electronics industry has prompted different regulations recently, including RoHS, or the Restriction of Hazardous Substances and Lead-Free, gaining its first appearance within the European Union through Directive 2002/95/EC. This directive bans the use of six hazardous chemicals in electrical and electronic equipment, and beginning July 1, 2006, all eligible products supplied in the EU market must be RoHS-compliant. RoHS compliance has a broad impact on the electronics industry, driving demand for lead-free surface treatments.

PCBX provides a convenient and free online price calculator to help you estimate the cost of PCBs with any of the following surface finishes. Click the button below to access the PCB quote page and see how prices vary with different surface finish options.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

The trend towards lead-free PCB manufacturing comes due to the EU's ROHS directive, which requires compliance to the limits on the content of lead. Compliance with lead-free is achieved by different surface finishes such as ENIG, ImAg, ImSn, and OSP—all with their different pros and cons. This paper compares these finishes to help choose the best for specific PCB applications.

Soldering forms a very important part in the assembly of a PCB. Wave soldering is ideally applied in Through-Hole Technology, while reflow soldering in Surface Mount Technology. Wave soldering involves flux spraying, pre-heating, soldering, and cooling, while in the case of reflow soldering, pre-heating, thermal soak, soldering, and cooling steps are applied. Temperature and time control are the two most critical parameters in the above-mentioned techniques for ensuring soldering reliability.

Most electronic circuits are mounted on PCBs, or Printed Circuit Boards, which provide mechanical support and electrical interconnection of electronic components. There are, however, special applications that involve the use of single and double-sided PCBs, multi-layer PCBs, or even rigid and flexible PCBs with aluminum backing, targeting medical, industrial, auto, and aerospace industries. They may use materials such as fiberglass, epoxy, aluminum, and others.