PCB Test Coupon

PCB test coupons simulate board elements for reliability checks, detecting early issues to ensure quality and performance before mass production.

Test coupons in a PCB are miniature mock-ups, representatives of key elements in actual PCBs for the purposes of testing and validation. These are integrative parts of the production panel, separate but alongside the main production boards. Such would include design features like trace geometries, vias, and layer configurations to match actual PCBs.

Its purpose is mainly to provide information about the manufacturability of the board and its long-term reliability. From these test coupons, engineers and manufacturers are able to glean from the early process what may be problematic and allow them to fix their problems before large-scale production. In this way, the test coupon becomes very helpful for avoiding huge, costly errors and generally controlling the quality of PCBs.

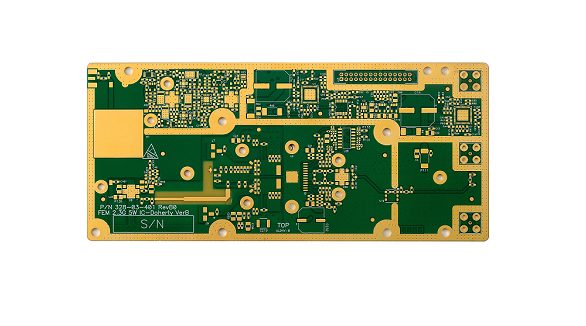

Structure and Design

The PCB test coupons act as the quality inspectors of the manufacturing process of a PCB. Ingeniously integrated into the margins of the layout of the PCB, they fit seamlessly in, much like pieces of a puzzle on the production panel. The test coupon hosts a pattern similar to that of the main PCB; thus, it provides an easy tool to assure that everything-line and connection-on the PCB is spot-on.

These are the same as actual test PCB materials, with layers of conductive copper sandwiched between sheets of non-conductive insulating material. The replication is thus often carried out very accurately, since it captures the features and functionalities of the final PCB design in order to see whether the board will behave correctly once it is put into use by devices.

Testing Procedure

And this is where the test coupons come in. These small-sized samples get firm-tested for reliability and performance in the final PCBs.

Electrical Testing: The electrical testing at the very frontline of tests offers assurance that electricity traverses along the circuits effortlessly. In other words, it can surely assure one that all electrical connections are intact; just like in the system of plumbing, there must not be any leakage. From the insights of test coupon into continuity and isolation, reliability is obtained in ensuring seamless electronic performance.

Thermal Stress Testing: These boards are subjected to varied temperatures when put into action, and this might affect their functionality. At this stage, the test coupons are subjected to extreme conditions of heat and cold, just like they might encounter in real life, to check upon thermal reliability. This stage confirms that a PCB can undergo fluctuations in temperature without its functionality being compromised.

Mechanical Stress Testing: The PCBs shall be able to support operational mechanical stresses. Test coupons undergo several different types of mechanical testing, including simulated bending, stretching, and twisting to be sure that they will stand up to everyday handling pressures. That means products, like smartphones, can sustain impacts and pressures.

All these careful processes of coupon testing will ensure that at the end, the PCB product will come with integrity, safety, and reliability before getting into the hands of the consumer.

Advantages

Higher Quality Assurance: Testing coupons of PCBs will significantly enhance the quality assurance process. Reliability proxies will take harsh forces of testing processes for the prediction and prevention of any failure that may be caused in critical applications. For industries where dependability matters, these components uphold a company's reputation for producing reliable and safe products.

Ongoing Performance Verification: Including test coupons on any given lot of PCBs provides for ongoing performance verification. In this regard, test coupons give fabricators the opportunity to periodically test their PCBs' functionality, and literally, each product must meet the highest possible standards. That is very significant in industries that involve very high-stake areas such as the aerospace or the medical technology sector, where the failure of even one product could not be allowed.

Early Problem Detection: A test coupon for PCBs acts like an early warning system where problems can be identified in advance and corrected as soon as they arise. It helps the manufacturer avoid expensive post-manufacturing fixes and eliminates waste on scraps of flawed products. Being able to correct the problems at such an early stage, the manufacturer saves a great amount of time and resources.

In all, the inclusion of the test coupon in the manufacture of a PCB is one strategic move that underlines the quality and reliability commitment of the manufacturer. Modest in appearance, test coupons play an important role in making sure printed circuit boards meet rigorous performance standards. They are almost a minor addition in the manufacturing process but monumental in impact on the product's reliability in the field. For the manufacturer, who would never want a single imperfect PCB leaving the factory, test coupons are a must-invest for product sustainability and consumers' trust.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Most electronic circuits are mounted on PCBs, or Printed Circuit Boards, which provide mechanical support and electrical interconnection of electronic components. There are, however, special applications that involve the use of single and double-sided PCBs, multi-layer PCBs, or even rigid and flexible PCBs with aluminum backing, targeting medical, industrial, auto, and aerospace industries. They may use materials such as fiberglass, epoxy, aluminum, and others.

The article insinuates the need for Organic Solderability Preservatives on printed circuit boards. OSP can adsorb onto the copper surface to prevent oxidation and moisture and can easily get washed out by soldering. It is easy to manufacture an OSP, which is environmentally friendly and not expensive, thus becoming one of the most popular surface finishes today.

Thermal management is all about more than just keeping the temperature of electronic systems and printed circuit boards low. It has been a key issue related to reliability and performance. Of the very basic fundamentals that would be studied in the field, some are concerned with methods of heat transfer. These are through conduction, convection, and radiation. The methods of cooling include natural cooling, forced-air cooling, fluid cooling, and evaporation cooling. Appropriate thermal design rules shall be followed wherein the chosen materials provide optimum thermal conductivity and the components of a system are so laid out that no hot-spotting will take place. Thermal analysis becomes critical in pointing out heat-related issues and optimizing the design. It thus minimizes failure rates and enhances stability and functionality of the electronic systems through comprehensive thermal management.