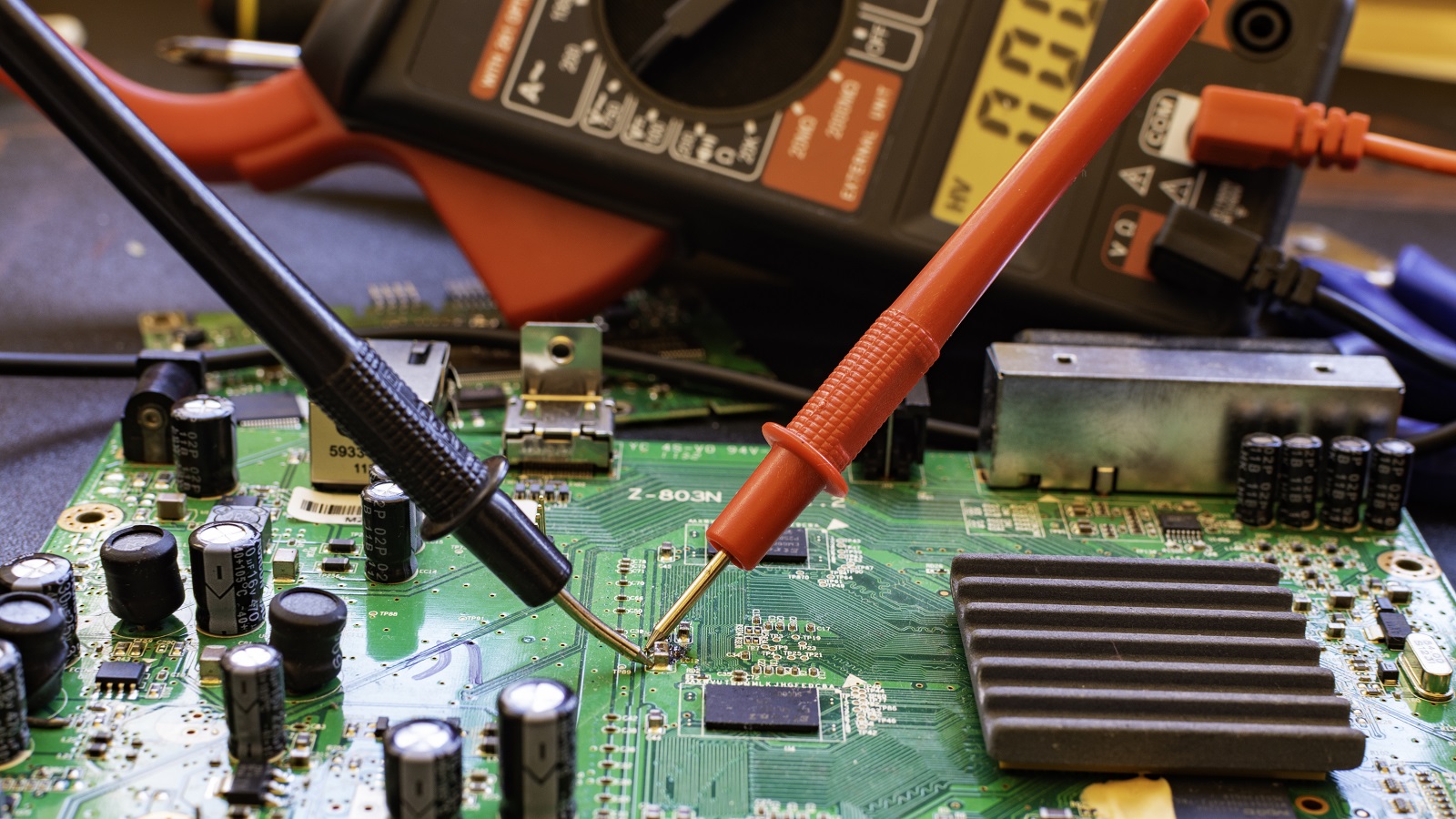

PCBA Testing

Superior PCBA testing ensures quality, functionality, and reliability, using diverse methods to prevent flaws, maintain standards, and enhance electronics manufacturing.

In the evolving world of electronics, it is critical that Printed Circuit Board Assemblies (PCBAs) are of superior quality so that manufacturers can uphold their reputations and customer confidence. PCBA testing is an integral aspect of manufacturing, ensuring that each circuit board not only functions as intended but also conforms to the highest levels of reliability and durability. This detailed analysis of PCBA testing highlights its importance, various testing processes employed, and best practices to provide excellence in electronics.

The Importance of PCBA Testing

PCBA testing is an important process control technique in the manufacturing process, with several advantages:

Quality Assurance: Pinpointing defects and inefficiencies before time keeps faulty products out of the marketplace. Performing it before time eliminates the cost of costly returns and warranty claims which damage the manufacturer's financial well-being and its reputation.

Functionality Verification: By ensuring that components operate correctly—right from IC programming to circuit continuity—testing is a gatekeeper of product functionality. It verifies parameters such as current, voltage, and power distribution on the board to make sure each assembly performs its designed function without failure.

Reliability Assurance: Testing simulates real-life conditions so that designers can predict how products will behave under stress over time. The ability to predict long-term reliability creates confidence in end-users and purchasers that they are receiving reliable, high-quality electronics.

Main Types of PCBA Testing

The variety of testing methods allows producers to choose the most effective one appropriate to fit specs, volume, and use of the product. The main types of PCBA testing are:

In-Circuit Test (ICT)

Functionality Check: ICT is a standard in production for checking the functional characteristics of all components on the board. ICT verifies the general electrical usability of the board through the measurement of voltage and current levels.

Thorough Analysis: ICT is beyond basic functionality and includes analysis of fluctuation curves, amplitude, and noise diagnostic. It aids in the identification of root causes that could influence PCB performance in the long term.

Functional Circuit Test (FCT)

Simulation of Actual Environment: FCT reproduces the environment in which the board operates for identifying hardware and software defects. FCT provides an understanding of the performance of the assembly in normal working conditions.

Holistic Validation: It keeps track of the overall performance of the unit, ensuring that every component of the PCB talks effectively to one another, thereby ensuring the board is ready for implementation in devices.

Flying Probe Test

Flexible Testing: It employs portable probes for electrical testing, being highly flexible without a need for specific fixtures. This flexibility makes it the best match for low-volume production and prototyping tests.

Detailed-Oriented Tests: The flying probe test tests component values and parameters with precision, giving detailed information that supports the iterative design process in R&D environments.

Aging Test

Durability and Stability Tests: By prolonged power-on operation for a predetermined period, the aging test emulates long running conditions. It aids in identifying components or assemblies that can lead to failure due to continuous usage and thereby estimate their operating life.

Environmental Stress Test

Severe Condition Testing: Subjecting PCBAs to extreme environmental conditions, this test examines boards for their tolerance against temperature, humidity, water, and mechanical shock. This real-world use stress testing simulates real-world application potential, challenging products' survival in extreme environments.

PCBA Testing Best Practices

To be good and reliable in the outcome of testing, integration of test factors at the onset of the design and production process should take place. The following best practices will lead to more efficient and effective testing:

Design for Testability (DFT): Employ DFT methodologies right from the start to make testing processes efficient and seamless. This involves detailed documentation of the design, clearly established test points, and due consideration of component placement for least obstruction in testing.

Personalized Testing Strategies: Design testing procedures to meet the specific use-case, application environment, and regulatory requirements. The personalized approach ensures thorough coverage of potential vulnerabilities and optimizes the test process according to the product lifecycle.

Optimization of Expertise: Collaboration with skilled PCBA manufacturers like PCBX optimizes testing. Such partners bring in expert technical acumen and advanced test facilities, enabling products to achieve the highest quality standards.

PCBA testing is an essential component in the production process of electronics, a cornerstone to product quality and reliability. By continued application of cutting-edge testing technologies, producers are able to identify and correct flaws prior to manufacturing moving forward, thus ensuring buyers get nothing but the best products. As technology continues to advance, so does the complexity and need for robust PCBA testing systems.

For manufacturers that desire the highest quality, partnering with experience-laden suppliers like PCBX brings true value. PCBX's comprehensive test services and leading-edge expertise ensure every PCBA is comprehensively tested for perfection, setting the stage for success in today's competitive electronics market. Contact PCBX today to enhance product quality and take advantage of expert PCBA test services grounded in precision and reliability.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Functional testing verifies PCB functionality in simulated environments, enhancing quality and reliability, detecting faults, ensuring performance, and cost efficiency.

FAI ensures the first PCBA production runs meet design specifications. Automation improves FAI by enhancing efficiency, accuracy, and reducing errors, transforming quality assurance in PCB assembly.

These SMT PCB assembly methods are involved, ensuring that several defects are detected. This includes the use of Automated Optical Inspection, In-Circuit Testing, and Automated X-ray Inspection. The combination of these methods is beneficial in facilitating an optimal inspection process.