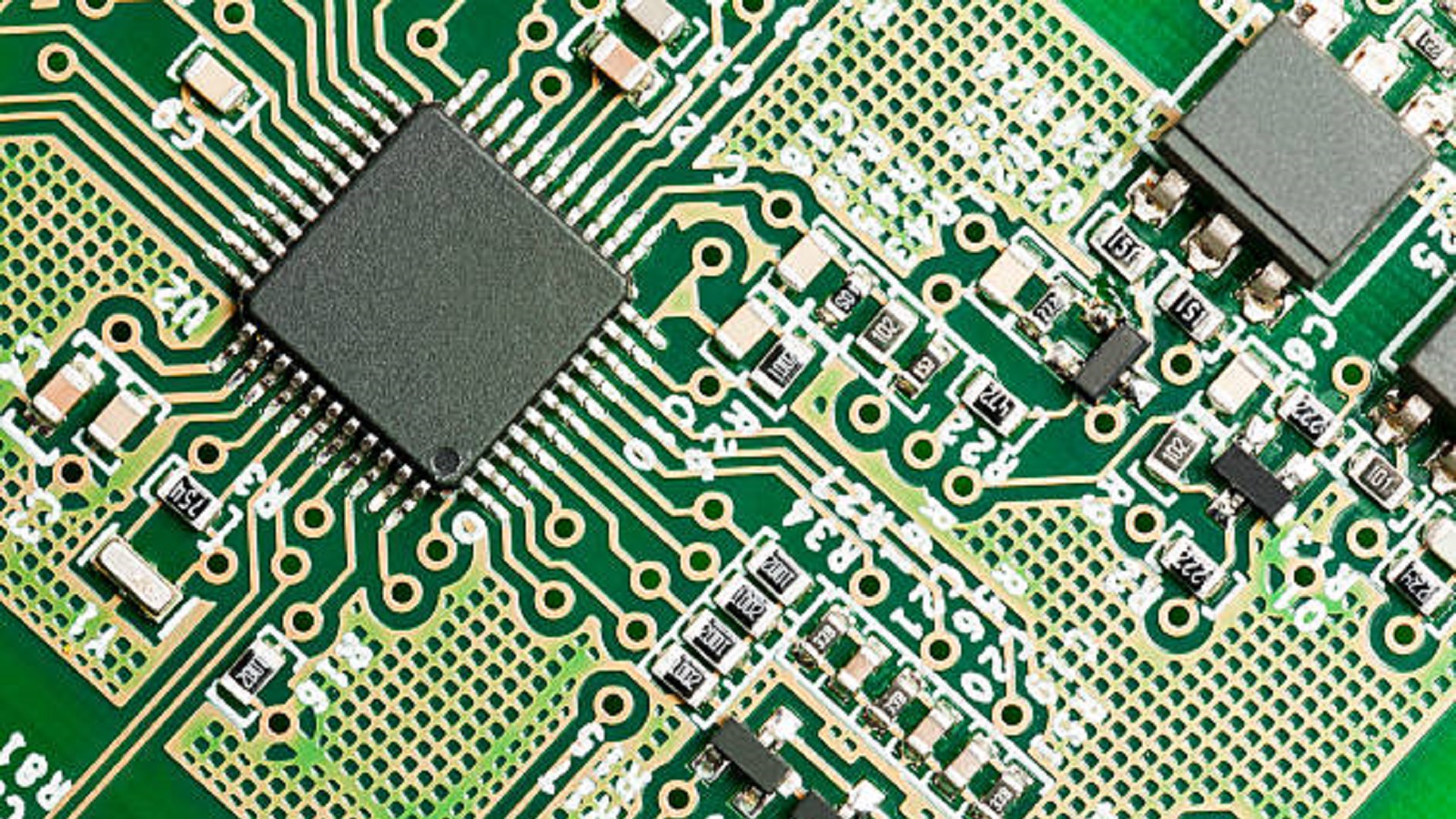

Populated Circuit Boards

Populated circuit boards integrate electronic components for efficiency and reliability, utilizing SMT and THT for diverse applications across industries.

The bare and the populated are two of the most basic divisions in the continuously changing world of electronics. Understanding the differences between these helps in further appreciation of the technology used in modern devices. A populated circuit board, sometimes called a PCB assembly, is at the heart of everything from consumer gadgets to advanced aerospace systems.

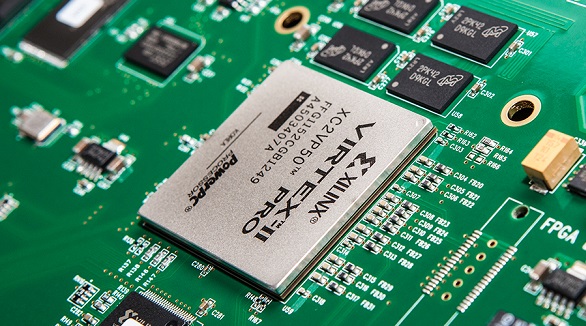

Basically, a populated circuit board is just a printed circuit board on which electronic components are installed. This contrasts with a bare circuit board that remains bereft of any sort of electronic component. From its mere board to a populated one, the entire process involves great planning and precision to attach components to the board for completing the electrical circuits effectively.

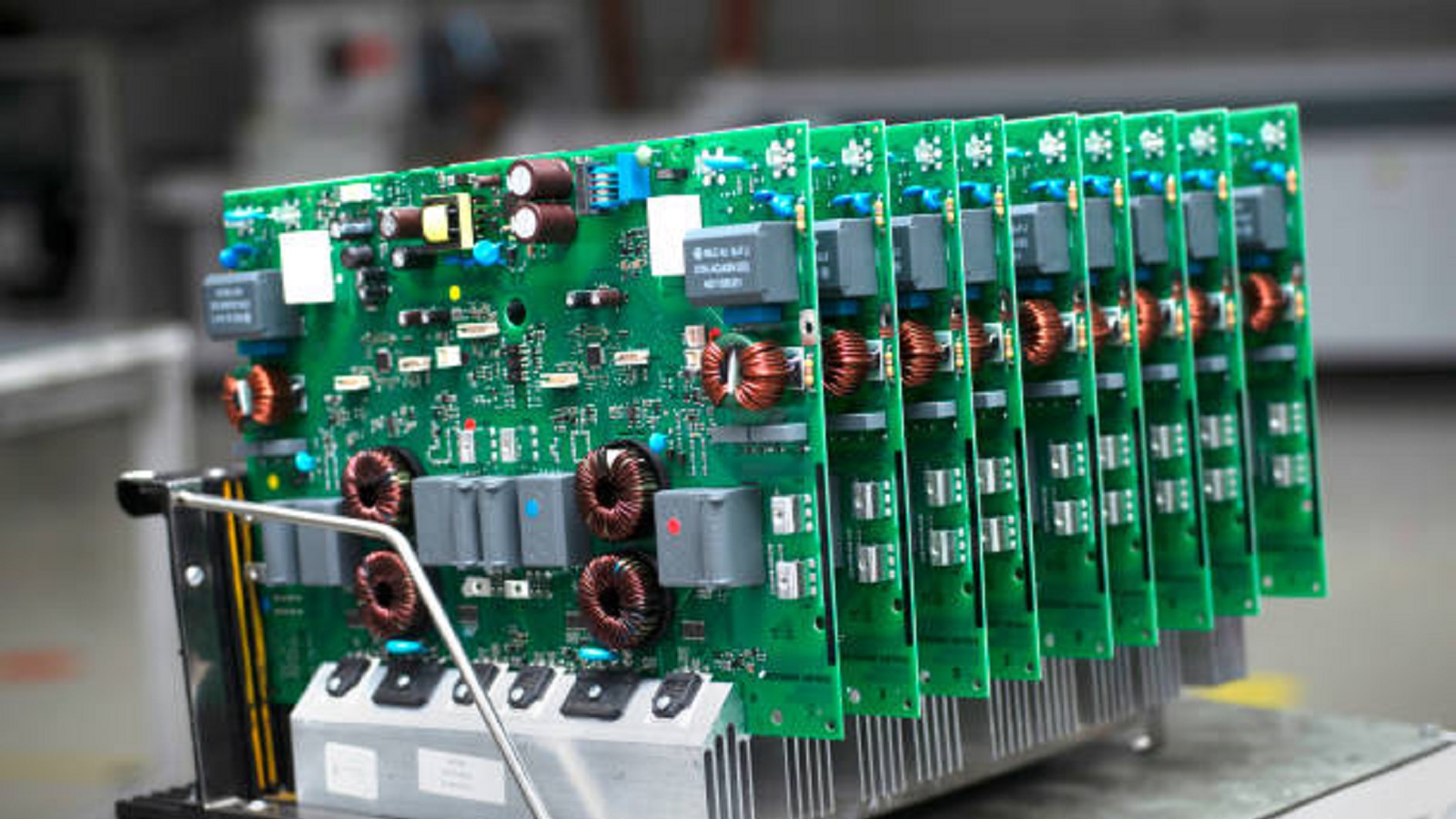

There are two main methodologies: Surface-Mount Technology for populating PCBs and Through-Hole Technology. Both methods have their advantages, and the choice of either largely depends on the project that is in view.

Surface-Mount Technology (SMT): SMT is a modern and widely applied method whereby components are directly mounted on the surface of the PCB. Automated machinery, such as pick-and-place machines, is generally used for placing surface-mount devices (SMDs) with a high degree of accuracy. The technique is preferred because of its efficiency and the ability to handle very small components, leading to compact and densely packed designs.

Through-Hole Technology (THT): The THT involves inserting component leads through holes drilled in the PCB. This method gives robust mechanical bonds and is often used for components that need greater physical support. Though THT was the standard before the advent of SMT, it remains valuable for specific applications where durability and reliability are needed.

The Components and Role of Populated Circuit Boards

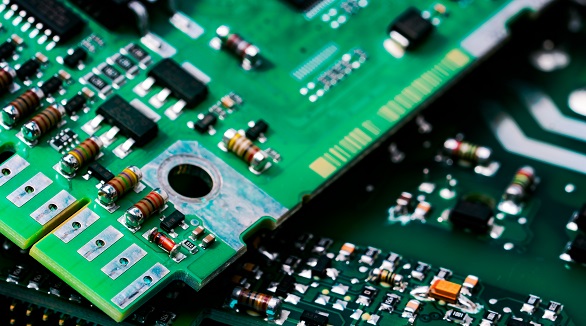

A populated circuit board has a very important role in different electronic gadgets, connecting electronic components with conductive tracks, pads, and components. Common components on a populated circuit board include integrated circuits, resistors, capacitors, diodes, and connectors. Each component has a certain role to play, whether processing signals, managing electrical currents, or ensuring energy storage.

These elements together execute complex operations, which is a crucial aspect to minimize electrical noise and to avoid loose connections. The design of the populated circuit board incorporates conductive pathways to connect the components, which enable easy signal processing and energy distribution across the board.

Factors Affecting Population

Following are various factors that can affect a bare board from getting transformed into a functional and fully populated circuit board:

Part Size: The size of electronic components varies widely and can influence the method and speed of assembly. For example, smaller components facilitate compact designs but require precise placement techniques like those offered by SMT.

Placement Velocity: It gives the speed at which a process of populating the PCB can be effectively executed, because the components are oriented correctly in the same direction and can be placed swiftly onto the board. Smoothing processes, like having components in the same direction, will facilitate the speed of assembling and reduce the likelihood of any errors.

Board Types: Whether the board is single-layer, double-layer, or multilayer, it will somewhat dictate the complexity and strategy for population. In particular, multilayer boards provide the greatest circuit density and demand more sophisticated techniques and technologies for correct assembly and functionality.

Advantages of Populated Circuit Boards

The use of populated circuit boards has several advantages:

Compact Design: This allows designers to directly mount components onto the PCB, thus enabling them to realize a more compact layout, which is critical in modern electronics where space is always in shortage.

Improved Performance: The populated circuit boards help reduce path lengths, which in turn reduce electromagnetic emissions, thus minimizing electrical noise. In this respect, better overall performance and reliability in electronic devices are achieved.

Ease of Maintenance: In populated circuit boards, the defective component can easily be identified and replaced without disturbing other circuits, making the repair and maintenance easy.

Applications of Populated Circuit Boards

Populated circuit boards are widely used in almost every industry and application. They include

Military: In military applications, the populated circuit boards are utilized in high-frequency technologies like communication devices and missile guidance systems where reliability and performance are paramount.

Consumer Electronics: Everything from smartphones to laptops, televisions, and even remote controls are filled circuit boards at their core. These provide the needed connectivity and functionality for complex operations.

Industrial Systems: Populated circuit boards are present in industrial machinery and equipment, like printers, vending machines, and surveillance systems where both mechanical and electrical robustness are needed.

Medical Equipments: These boards form an essential part of diagnostic and therapeutic equipment in the medical field, from CAT scanners to ultrasound machines, offering the precision and dependability expected in a critical environment.

Aerospace: The circuit boards with full population have a wide application area in high-frequency and high-speed technologies in aerospace systems and satellite communication.

Populated circuit boards are really indispensable in the electronic industry. At PCBX, comprehensive services in the manufacturing of PCBs and PCB assembly are provided for various clients across industries. The understanding of the nuances in populated circuit boards highlights not only the importance but also the innovative drive to electronic advancement. For your every PCB requirement, get in touch with the quote for the manufacturing and assembly at PCBX today and leverage our experience for your next project.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Surface Mount Technology revolutionizes electronics, offering size, cost, and performance benefits, but poses challenges with high setup costs and handling.

Through-Hole Technology (THT) mounts electronic components by inserting their leads through pre-drilled PCB holes and soldering them. While durable and ideal for harsh conditions, THT is less space-efficient than SMT.

Ball Grid Array (BGA) components, such as PBGA, CBGA, CCGA, TBGA, and CSP, provide high I/O density, improved reliability, and high-quality electrical and thermal performance. Quality assembly and functionality are assured since advanced soldering and inspection methods are required, like AXI and AOI. Proper storage and handling shall guarantee the performance of the devices.