Printed Circuit Board Assembly Benefits

PCBs enable miniaturization, efficiency, and cost-effectiveness in electronics. Automated assembly further reduces costs, enhances accuracy, speeds production, and ensures quality.

Printed circuit boards (PCBs) are essential components in all daily electronic devices, from smartphones and computers to televisions. This article explores the key benefits of PCBs and the advantages of automated assembly.

Benefits of PCBs:

- Miniaturization: PCBs allow for a significant reduction in device size compared to traditional wiring methods because they utilize copper tracks etched onto the board instead of bulky wires. This miniaturization has been a major driver of advancements in various electronic devices.

- Efficiency and Reliability: PCBs save time and effort during assembly compared to traditional methods. The connections are more reliable and less prone to loose wires or short circuits to ensure a more dependable and durable final product.

- Cost-Effectiveness: Mass production of PCBs is cost-efficient, especially after the initial design and testing phase. This affordability allows manufacturers to create various electronic goods at accessible prices.

Advantages of Automated PCB Assembly:

- Reduced Costs: Automation minimizes errors and the need for manual labor, leading to lower overall production costs.

- Enhanced Accuracy: Machines excel at repetitive tasks and are less susceptible to human error, ensuring consistent and precise PCB assembly.

- Faster Production: Automated assembly significantly reduces production time compared to hand assembly, allowing quicker product development cycles.

- Consistent Quality: Automation ensures consistent quality across all manufactured PCBs, eliminating inconsistencies that can occur with manual assembly.

- Scalability: Automated assembly is ideal for mass production, allowing for the creation of large volumes of PCBs efficiently and cost-effectively.

- In conclusion, PCBs are a cornerstone of modern electronics, enabling miniaturization, efficiency, and reliability. Automated PCB assembly further enhances these benefits by reducing costs, improving accuracy, and streamlining production. This combination makes PCBs a powerful technology for the development and production of a vast array of electronic devices.

Select PCBX for PCB Assembly Services

Printed circuit board assembly is now more affordable, more accurate, and faster due to automation. This allows PCB designers to receive a professional service of large-scale production on small-volume and high-volume orders. If you require circuit board assembly services, please get in touch with one of our PCB specialists.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Turnkey PCB assembly means the provider handles everything from component procurement to manufacturing and assembly. PCBX, serving 80+ countries, offers reliable, cost-saving, one-stop solutions with faster lead times and consistent quality.

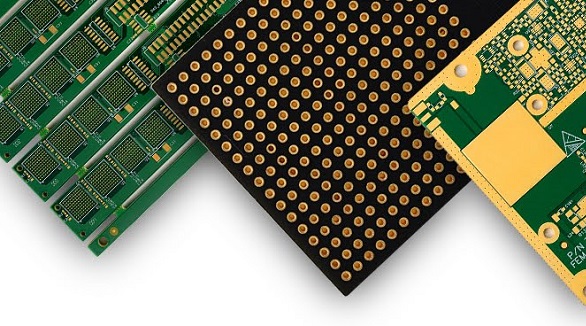

Multilayer PCBs, essential for advanced electronics, offer compact size, lightweight, and high performance, making them ideal for various applications despite higher costs and complexity.

One is a bare circuitry board, and another has all the components and is functional: PCB stands for Printed Circuit Board, and PCBA stands for Printed Circuit Board Assembly. PCB acts like a base, and components are assembled on it at a later stage through various methods in PCBA, such as SMT and Thru-Hole Technology.