Prototype PCB Assembly

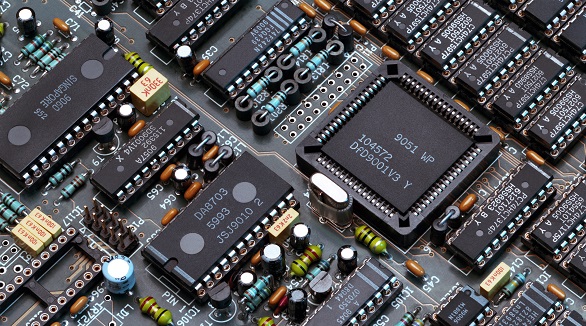

PCBX offers fast, high-quality turn-key PCB prototype assembly services, including fabrication, component sourcing, and testing, all at competitive prices, to accelerate product development.

PCBX provides prototype assembly services with high-end fabrication and component procurement services, which enables fast, efficient, prototype assemblies, taking your unique PCB designs and preparing them for the assembly process, and then rigorously testing the finished assemblies to meet your exacting performance requirements. Our complete turn-key PCB prototype assembly service operates in a one-stop configuration to minimize your time, cost, and trouble.

Benefits of PCB Prototype Assembly

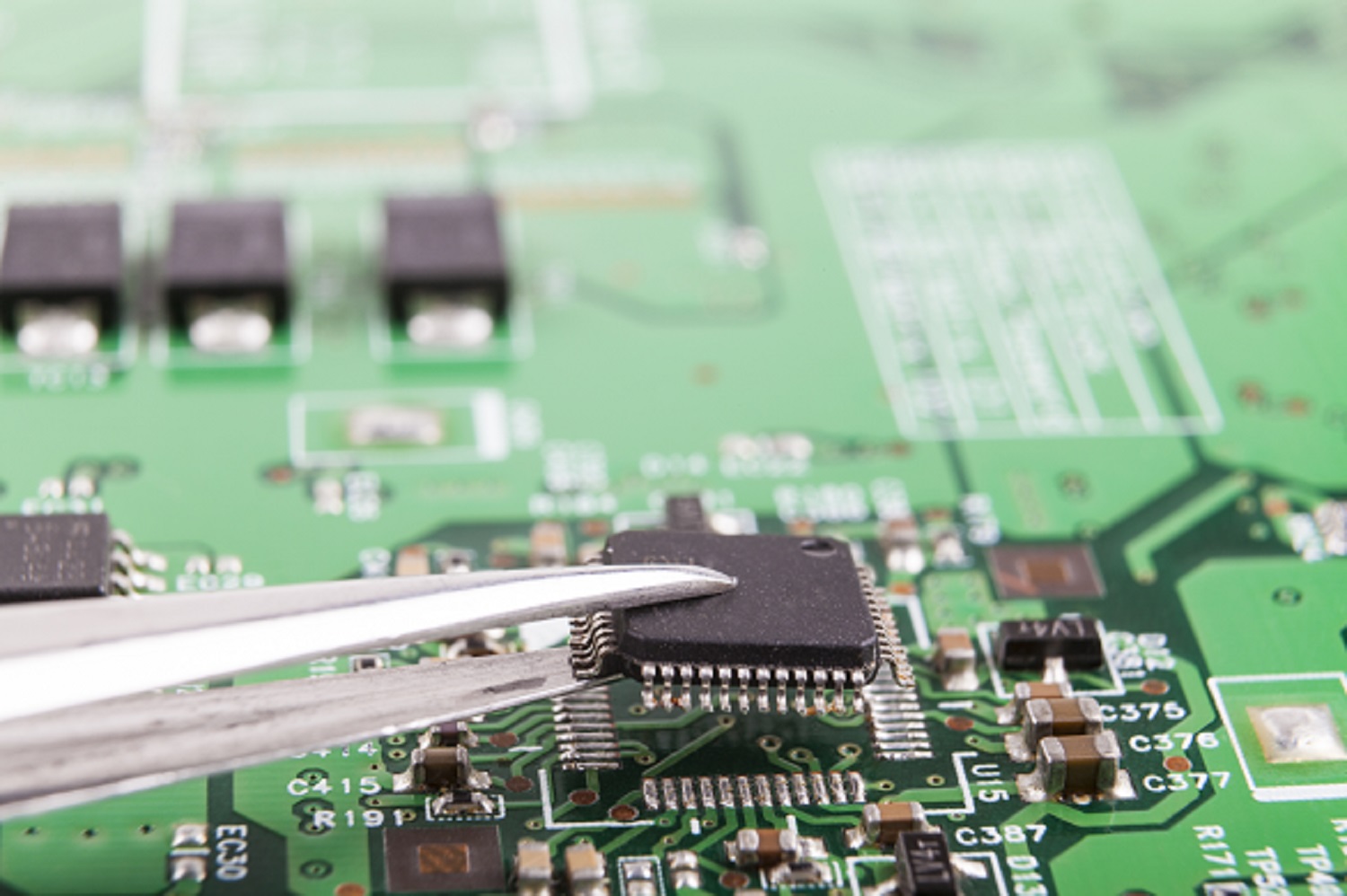

Ordering a PCB prototype is critical for testing the performance of your PCB design quickly, and this usually wouldn't be possible without assembly. To save time while determining the performance of your assembled PCB prototype, PCBX provides in-house PCB prototype assembly.

With the help of PCBX, there is no need to make the PCB separately and seek a professional to do prototype assembly. Work with us, and let's make this all efficient on your own.

PCB Prototype Assembly with High-Quality Standards

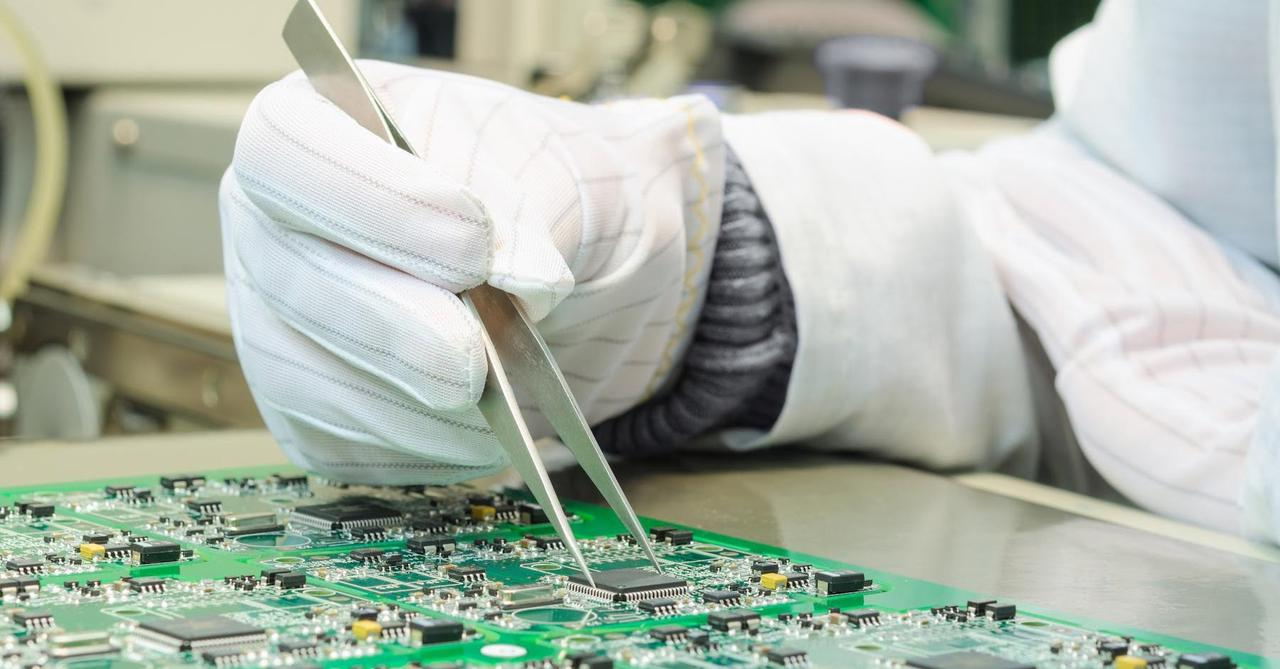

Prototype assembly is generally a small-volume production. However, at PCBX, prototype assembly is not any different from our high-quality standards and extreme care in handling the projects to the scale we deploy in our mass production assembly. We use the same unmatched resources and seasoned workforce for the best results. Our expertise can manage the whole process, from part and component sourcing to PCB fabrication and assembly production to full quality control. We always adhere to your original prototype design and never make any modifications without your permission.

Our prototype to production display also includes DFM (Design for Manufacturability) and DFT (Design for Testing) services to make your prototype a reality based on your specific design requirements. We are also able to assemble prototypes for complex, high-density FR-4 circuit boards.

You Can Count on Our Fast Project Turnaround Times

PCBX can deliver your PCB assembly prototype in weeks or even days. This accelerated timeline enables you to move into production sooner, allowing you to start generating profits more quickly. We can make this promise with our flexible assembly options, extensive component availability, and strong, long-term partnerships with authorized component distributors and manufacturers. You can quickly check if your design requires adjustments or it proves unworkable during final assembly, which gives you a valuable opportunity to refine your design and achieve a finished product well.

In the fast-paced world of business, particularly in consumer electronics, being first to market means capturing a significant portion of the profits. With our fast PCB prototype fabrication and assembly services, PCBX aspires to make you the market leader.

Prototype PCB Assembly at Competitive Prices

PCBX aims to reduce the cost of your PCB prototype assembly in many ways. We work with several well-known sources for components, allowing us to get what you need at the best price, without reducing quality. Combine this with several lower-cost packaging options and sophisticated tools to help determine which package style is best for your project.

With one-stop PCB solution that include printed circuit board fabrication, component sourcing, and prototype assembly, PCBX is the best choice. The entire process is completed in-house by experienced engineers and design team, to ensure seamless communication to ensure that you can get exactly the prototype you need quickly and reliably.

To receive a quote of PCB prototype assembly for your custom PCB project, simply click the button below to send us your circuit specs and BOM (Bill of Materials), and we will reply within 48 hours.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

PCBs enable miniaturization, efficiency, and cost-effectiveness in electronics. Automated assembly further reduces costs, enhances accuracy, speeds production, and ensures quality.

PCB prototyping is vital for testing and refining electronic circuits before mass production, ensuring performance and feasibility using methods like etching, milling, and 3D printing.

Customers prefer one-stop PCBA service not only because of price transparency; it can save time and reduce labor costs with efficiency and professionalism in procurement and production.