Prototype PCB Benefits

Creating PCB prototypes before full production avoids potential failures, saves costs, and ensures quality. PCBX offers rapid, accurate prototyping for efficient testing and design validation.

Since PCB is widely used to form integral parts of most types of electronic devices, it would be huge damage owing to their failure or poor performance after production. To avoid such risks, it is essential to create a PCB prototype before going into full production.

How PCB Prototype Help in Design

PCB prototype is considered in the design cycle for testing the functionality of a PCB-based solution very early in the cycle. By executing several prototype runs, redesigns can be validated or individual functions be isolated before progressing to more intricate designs, thus enabling the iteration that empowers the fixing of probable problems sooner to avoid extra cost.

The Critical Role of Quality Prototyping

Effective PCB prototyping requires fast production for quality prototypes that resemble the final product in terms of parameters and functionality. PCBX is committed to offering a rapid and accurate prototype engineering service targeting a broad range of project scales with our minimum order quantity.

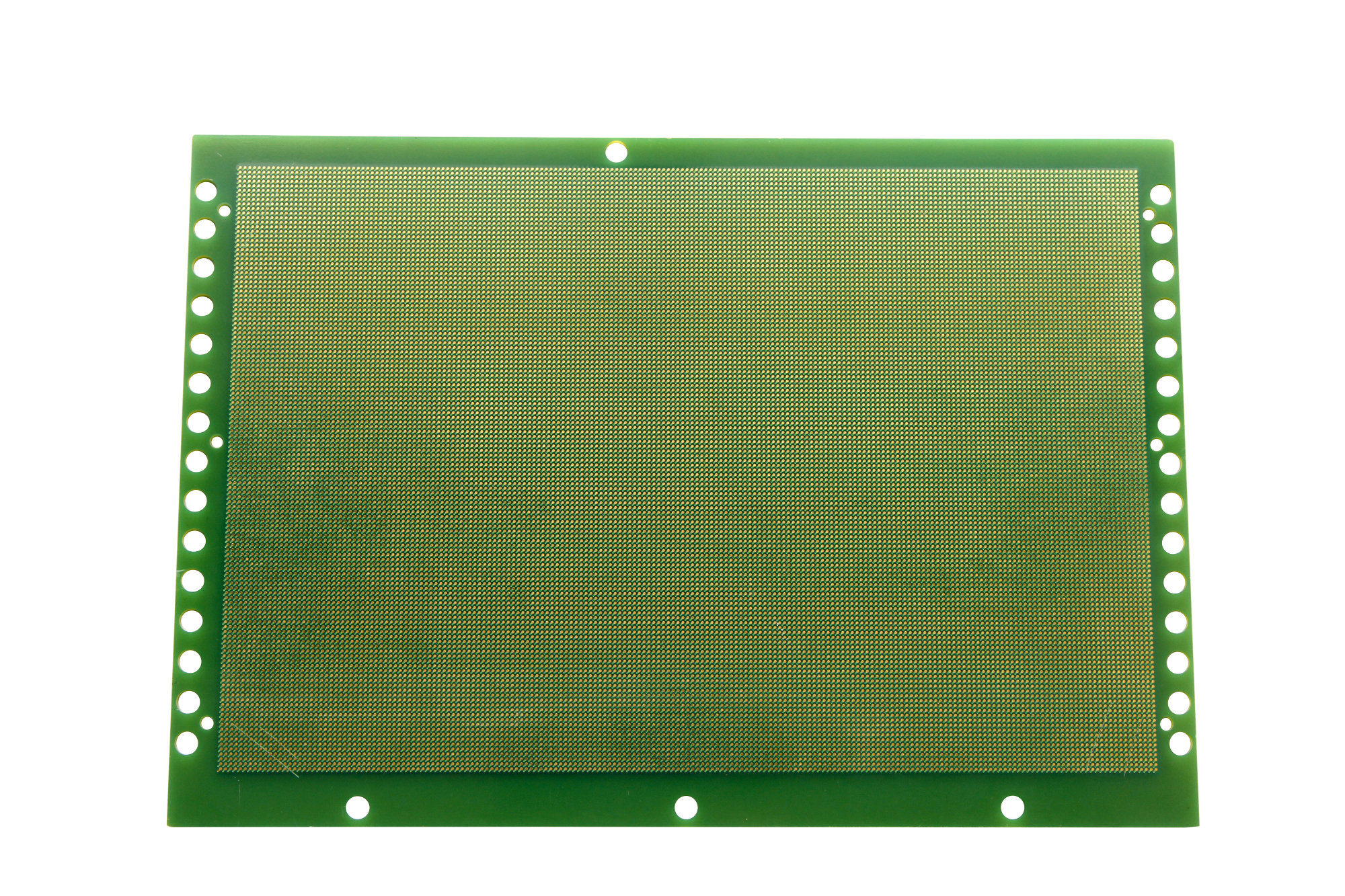

Prototype PCB vs. Standard Production PCB

Prototype boards are far from being production boards, not offering many advanced options implemented in the full-production versions and lesser production tolerances, but they are sufficient to check whether your designs meet the performance and quality criteria specified.

Lead Time & Order Quantities

PCBX offers rapid prototyping services for modest orders ranging from 5 to 100 pcs. Standard production volumes range from one to over 10,000 pieces.

Differences in Specifications and Materials

The specifications for prototype and standard PCB also differ. Prototype PCB meets the IPC1 quality standard while standard PCB IPC2 and Prototype PCB only use R4 material while standard one can be done in a wide range of materials like R4, aluminum, and flex-rigid materials.

Layer Capabilities

Standard PCB can have a higher number of layers compared to prototype one, the former with up to 8 layers, while the latter with up to 32, which provides standard boards with a higher thickness than prototype boards. The minimum thickness is the same, but the maximum is somewhat higher than the standard.

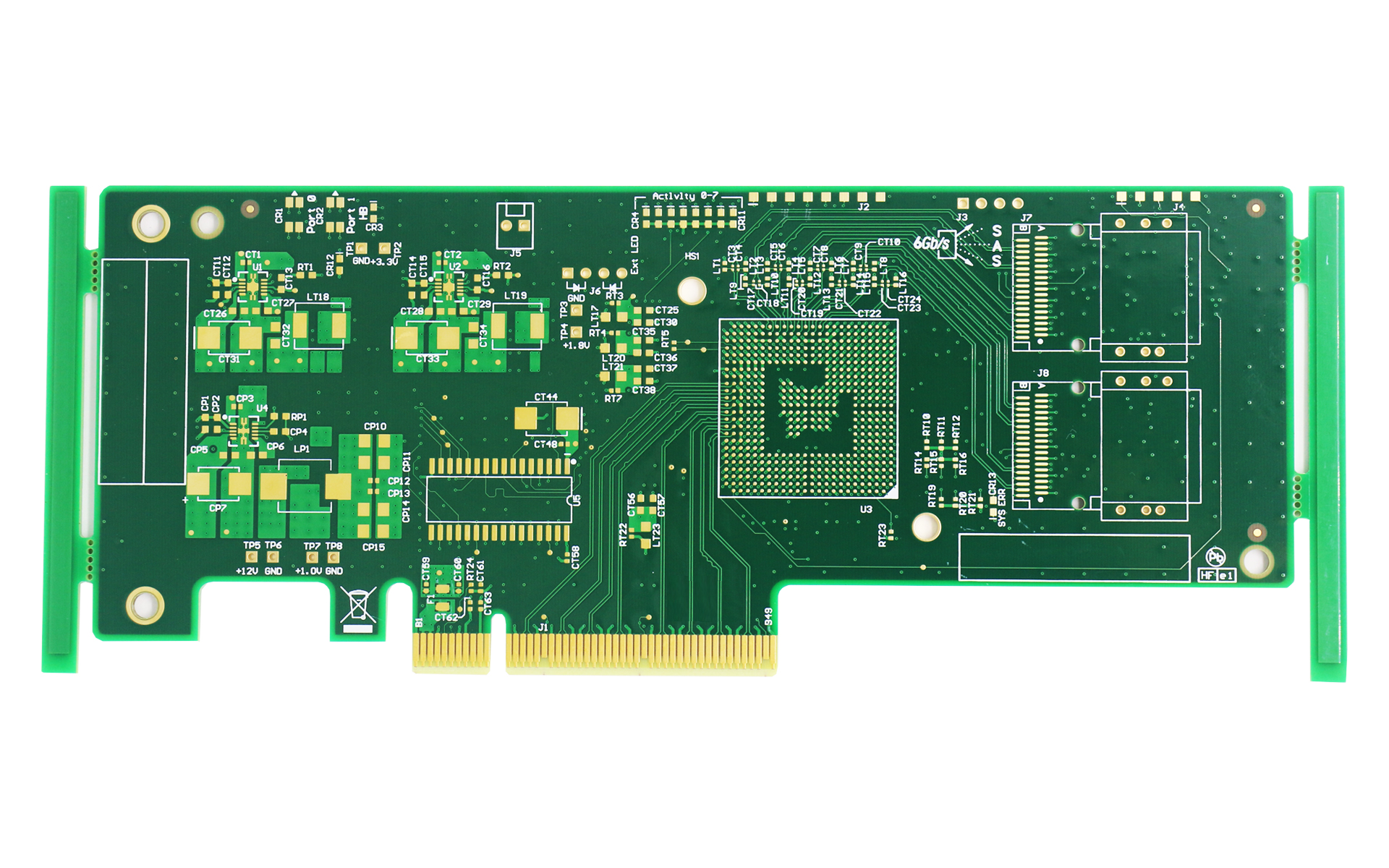

32-layer high-precision PCB

Standard PCB is available with a much wider range of surface finish options than those available for prototype PCB. The surface finishes are placed over the exposed copper circuitry to prevent corrosion and provide a solderable surface for further components attached to the prototype. There are two common methods for prototypes: HAL or ENIG with RoHS-compliant alternatives available for each. In contrast, standard production PCB can be finished using HAL, ENIG, Electroless Nickel / Electroless Palladium Immersion Gold (ENEPIG), Immersion Silver, Immersion Tin, and Organic Solderability Preservatives (OSP).

Advanced Features in Standard Production

Prototypes, while useful for preliminary testing and design validation, may not support some advanced features of standard production PCB, including:

Impedance Control: Preserving consistent transmission of signals by keeping the impedance of traces in a PCB consistent.

Gold Fingers: Connectors plated with gold at the edges.

UL Marking/Date Code Marking: Marks of compliance and oneness.

Buried/Blind Vias: The VIAs don't permeate the entire PCB to allow for complicated designs in multilayer boards.

Peelable Solder Mask: Temporary solder mask, peelable after soldering.

Edge Plating: Conductive plating on the edges between the layers of the PCB to enhance connectivity.

Carbon Mask: Carbon-based ink, conductive, for keypad contacts.

Kapton Tape: High-temperature tape used in the soldering process to protect areas.

Countersink/Counterbore Holes: Holes whose edges have been specially machined to mount specific components.

Half-Cut/Castellated Holes: Partially routed holes for edge connection.

Press Fit Holes: Holes that are designed for tight fitting of component leads without solder.

Via In Pad: Vias right on top of solder pads for component connection.

Solder-Stop Coating Bridge: Protective coating to prevent solder bridging between components.

Why Use a PCB Prototype?

Why is a PCB prototype needed when regular production runs? It seems like adding an extra step while using a prototype ultimately saves you time and money, and maximizes the quality of your final product.

Iterative Design and Cost Efficiency

The development of a new design based on PCB may incur iterative demands, while such designs must be tested fast to avoid the resulting time costs to stay within the schedule of production. With PCBX's fast prototyping service, you will be able to test your design fast before full production, which helps reduce any undue spending and maximizes return on investment.

An oversight on the design or efficiency is much more expensive to find out later in production than during the prototype phase. Without the prototype, such a problem is only identified when hundreds or thousands of standard PCBs have already been ordered, which would cause extra time and cost loss. PCBX provides prototyping services in handy for low-volume production runs where only a minimum of five boards apply to an order.

Single Function Test

Engineers often make prototype PCBs to test single functions of more complex products that may have multiple PCBs. First, a prototype is made that represents the simplest function; additional capabilities are then added incrementally. If single-function tests are skipped, it is difficult to find the offending board that causes performance failure. Such debugging, when needed, can take a great amount of time and resources, while that could have been avoided with prototype incremental steps.

Manufacturing Accuracy and Features

While prototype PCBs don't have the same high manufacturing tolerances that will be allowable in standard production runs, they are still very effective and reliable ways to test how a final PCB-based solution will operate. We can also produce prototypes that look like the end-product solution and perform a similarly functioning solution—all at slightly lower manufacturing tolerances and without some advanced features. However, we do take steps to ensure that our prototype boards reflect an accurate portrayal of the functionality of the intended final standard production PCB techniques.

Transition to Standard Production

Once you've fully validated your design using prototype boards, you can move to a standard production run. PCBX also offers standard runs where the tolerances and capabilities are tightened, better suited for orders of larger volumes. Part of our standard production offering includes a Design for Manufacture (DFM) analysis that highlights any potential manufacturing issues. If anything goes wrong, we work with you to develop the solution.

Maximizing the Success of Projects

While developing a new product or looking to redesign, our prototype PCB production service can help tremendously in the identification and rectification of any potential issues or changes a design may go through at the very beginning of a project, which saves you loads of time and money. Meanwhile, this approach provides better financial performance for the project and a better-quality end product, therefore contributing a lot to its success.

PCB Prototype Advantages

Selecting prototypes of PCBs instead of jumping directly into standard production has many benefits. In cases where there's a new or updated design, prototyping could go a long way in being very helpful. Some of the benefits associated with PCBX prototyping include:

Fast Turnaround Time

We can prototype a PCB at a much faster rate than the standard production of PCB, with prototypes taking as short as two days, while for standard production PCB up to three to 18 days. The normal build time for prototypes is two to five days, which means that with this quick turn-around time, new designs can be tested to facilitate the process of your project.

Early Flaw Detection

Before significant investment of time and money in possibly flawed designs, prototyping allows one to pick up the faults in design at a very early stage of development. Very early engineering changes help to avoid a whole list of potential issues that may affect many different areas of your project.

Individual Component Testing

This is very helpful, specifically for the kinds of projects that incorporate multi-element components, where each of the elements involves a separate PCB. The parts can be proven to work independently, and any problems will manifest as originating with one or the other component. Without individual testing, when performance is not correct in a multi-PCB component, the whole unit either has to be scrapped or divided into parts. It is much easier to start with individual testing.

Accurate Performance Representation

High-quality prototype PCBs tend to be very close to an accurate representation of how the final production component will perform. These prototypes will allow a very reliable indication of what to expect in a standard production run, even while having lesser tolerances.

Get Projects Done Efficiently

In the case of flaws in the design, PCB prototyping aids in early detection and correction and easily enables one to identify the components that need adjustment quickly. Without prototyping, the detection of flaws and their cause would have taken much more time, hence extending the timeline of the project, which is certainly going to cause lost revenues and customer dissatisfaction.

Lower Overall Costs

This advanced planning can help bring down the total cost that a certain project involves. Very early identification of problems will allow fixing them before any serious investment in a high-volume production run. Once the problem is identified in this easier-to-work-with prototype version, one can rework that component at a fraction of what it would cost to address an issue in the entire project.

Improved End Product

PCB prototyping ensures this superiority is transfixed into each PCB and component, thus achieving better quality designs, which ensures that some malfunctioning goes undetected in final products and causes more significant issues much later.

Considering all the associated advantages of prototyping PCBs, it's recommended for most projects that include new or revised PCB designs. Once benefit from the prototype advantages, you can progress to standard production runs with a final product that's polished and reliable.

PCB Prototype Applications

Printed circuit boards, connecting components through various related circuits, are at the heart of the many different electronic devices that we use every day. They come in many different variations, which allows them to perform under a wide range of circumstances. PCBs are an integral part of electronics used across nearly every industry. You can find them in consumer electronics, medical devices, automotive components, industrial equipment, lighting technologies, aerospace instrumentation, and more.

As people continue to innovate and create more new electronic devices, PCBs become even more common. It is in the development of these new products that prototype PCBs are most useful. You should consider prototyping if your project involves any of the following conditions:

• New products Any time your project involves developing a new product, you should use PCB prototyping. Without prototyping, you may not detect any existing issues before they cause more severe problems or become more difficult to fix. Even if your project is very similar to another that you've already completed, prototyping can be helpful. Many factors go into a device's performance and prototyping enables you to quickly and economically identify any of those factors you need to adjust.

• Quality and design testing If you want to perform quality testing or design review, you should order PCB prototypes. The shorter build time will allow you to begin conducting your review or testing sooner and will reduce your overall costs. PCB prototypes will give you an accurate idea of how your final product will perform. They enable you to verify quality and performance before you invest in a larger standard production run, helping you to complete your project quicker or more cost-effectively.

• Complex components If your project contains multiple PCB-based components, you should use PCB prototypes. More components can mean more functionality but also more potential failures. With these more complex projects, prototyping is especially useful, as it helps to quickly identify which component is not performing correctly. You'll spend less time testing and correcting problems that arise and save money by ordering one PCB at a time.

• Modeling purposes If you want to present your physical design but don't need the board to function, you should use a prototype. In some situations, you may wish to have a model of your design to illustrate how it will work. In these cases, you don't need a fully functioning board, only an accurate representation of the design. Using a prototype for this visual can be a more cost-effective option than using a standard production board.

Order PCB Prototypes From PCBX

PCBX provides a one-stop shop for all your needs, whether in PCB prototyping or standard production. Our services from component procurement through fabrication, assembly, and quality control in the entire process of prototyping, could avoid coordination time with multiple suppliers, and save time and money.

Commitment to Quality and Details

Quality is important to us, and we will follow your design specifications to a 'T'. We won't make changes without your approval, and if any problems do happen, we will work with you to correct them. Our fast customer service response time sets us apart, and everyone deserves this personalized care.

Easy Online Quote

We have added an intuitive online quotation calculator through which consumers can obtain custom PCB prototypes and production easily. Fill in the requirements of your specifications and items needed, and you get a free quote instantly.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.