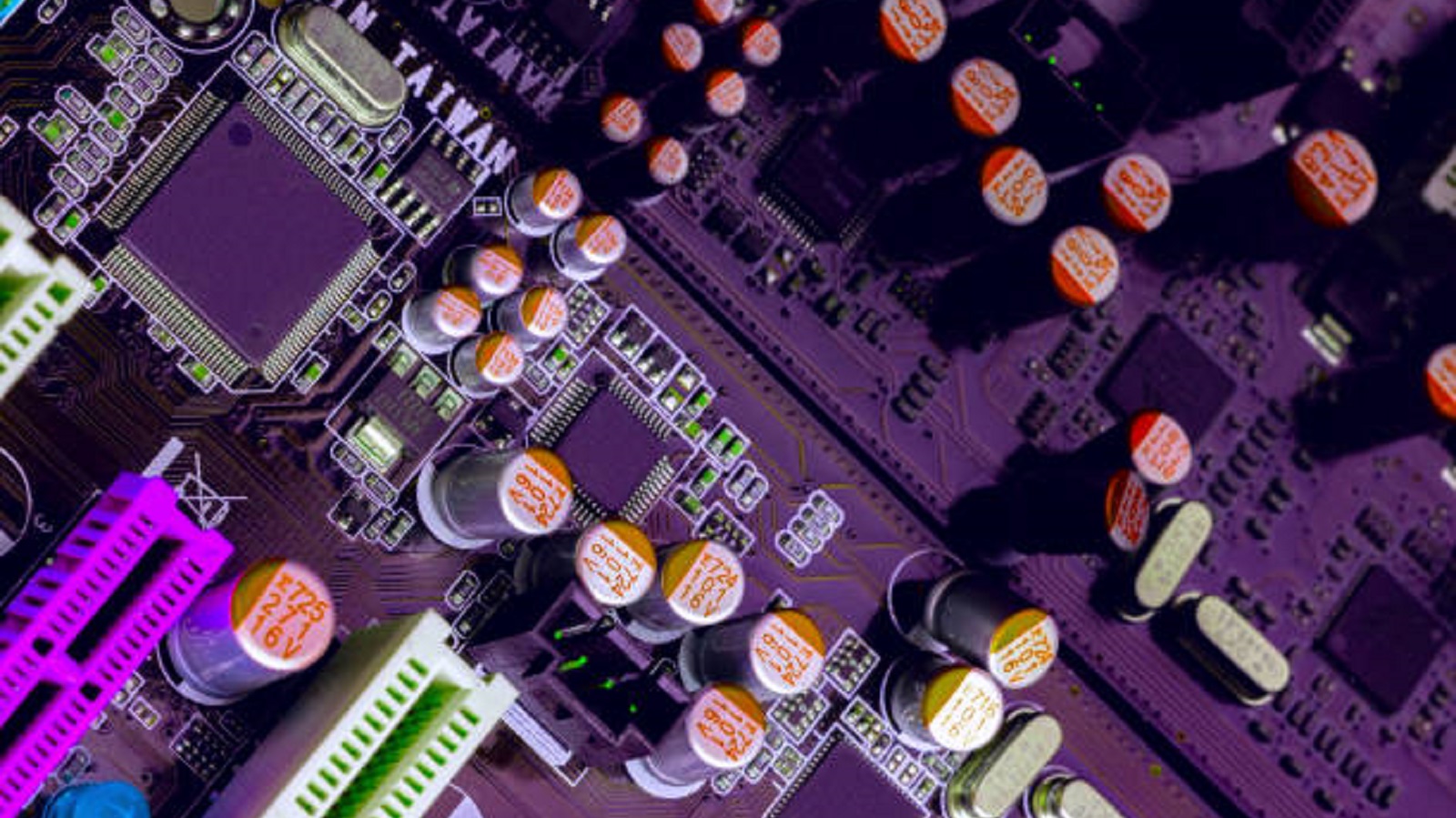

Purple PCB

Purple PCBs offer aesthetic and technical benefits, enhancing contrast and performance. Ideal for various industries, they require careful manufacturing for best results.

Printed circuit boards, in particular, form the basis of any electronic device. Conventionally, these boards have been green, but purple PCBs are now stealing the spotlight with the industry's growing move to bright colors. Driven by aesthetics, branding, and performance, purple PCBs have their advantages for a number of different applications. This article is meant to discuss the properties, advantages, disadvantages, and manufacturing aspects of purple PCBs.

The solder mask has numerous uses on a PCB, the protection of copper traces from oxidation, insulation, mechanical support, and chemical resistance. While green has been the go-to color due to its visibility and historical use, the industry now offers a spectrum of options including blue, red, white, black, yellow, and purple.

As aesthetic and technical advantages are more profound with purple solder masks, there has been a considerable move toward them. Let's explore what makes purple PCBs worth the effort for today's electronics applications.

Why Purple?

Aesthetic and Branding Appeal: Purple PCBs offer a distinctive look that is striking, making them perfect for consumer electronics whose goal is to create brand differentiation. The color also appeals to target demographics with the power of creative and catchy designs.

Improved Contrast: The complementary nature of purple enhances contrast against copper and the FR-4 substrate, which improves the inspectability of circuit patterns. This helps the automated optical inspection systems in their jobs of detecting defects.

Technical Performance: Purple masks exhibit very good dielectric performance with low signal loss, which is well-suited for high-frequency RF applications up to 5G. In addition, these masks are capable of withstanding the higher soldering temperatures associated with lead-free processes without yellowing at the elevated temperatures.

Industries Using Purple PCBs

Purple PCBs are finding their way into different industries because of their aesthetic and technical advantages:

Consumer Electronics: Applied to smartphones, tablets, audio-visual, and gaming equipment.

Automotive: They are very suitable for units of infotainment systems, ADAS modules, and lighting control.

Medical Devices: They are also applied to monitoring systems, imaging equipment, and therapeutic devices.

Aerospace and Defense: They are suited for avionics, radar systems, and satellite components.

Instrumentation: They are applied to industrial sensors, process control boards, and IoT applications.

Producing Purple Solder Masks

There are two dominant ways to achieve purple solder masks:

Pigmented Masks: Adding purple pigments to the solder mask material provides opacity. This may involve thicker masks to achieve but the color is consistent.

Base Mask w/ Purple Legend Ink: A base mask is applied, such as white, then overcoated with purple legend ink. Colors are deep, yet the overall thickness is minimal. Printing registration must be accurate.

Design Considerations for Purple PCBs

When designing purple solder masks, consider:

Mask Thickness: Thicker masks may require adjustments in spacing.

Legend Printing: Provide for tight registration tolerances.

Component and Copper Contrast: Provide contrasting markings to avoid blending.

Solderability: Check fully cured masks for good solder wetting.

AOI Optimization: Adjust inspection systems for the new color.

Advantages and Disadvantages of Purple Solder Masks

Advantages:

Unique aesthetic appearance

Very good contrast for inspections

Good signal performance in RF applications

Durable under lead-free soldering temperatures

Disadvantages:

Potential for color consistency

Increased production cost

Possible registration issues with legend ink

Finding a Manufacturer

How to source quality purple PCBs:

Request samples for color and quality evaluation.

Validate adherence to IPC standards and manufacturing capabilities.

Evaluate print techniques and surface finish compatibility.

Prioritize manufacturers with strong engineering support for design and production insights.

In conclusion, purple PCBs are a great evolution in the PCB industry, providing both aesthetic and technical advantages. Whether you're going after aesthetic innovation or performance metrics, the minute details of purple PCBs are very important, which can definitely help you apply the full potential in your designs.

Choose PCBX for PCB Manufacturing

When considering a manufacturer for your purple PCBs, choose PCBX for exceptional quality and service. PCBX offers advanced manufacturing techniques, rigorous quality standards, and a commitment to customer satisfaction. Our experienced team is ready to assist with your design and production needs, making PCBX the ideal partner for your innovative PCB projects.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

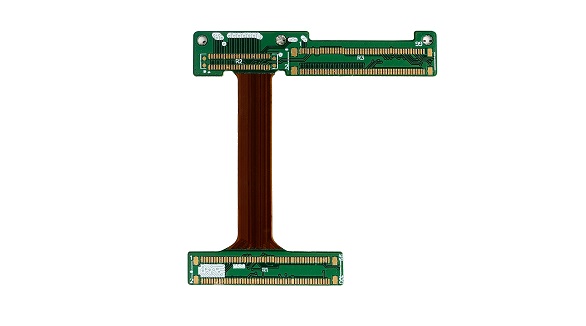

Carrier PCBs are crucial for data modulation, multiplexing, and network integration, supporting efficient and robust telecom infrastructures globally.

Black FR4 PCBs offer aesthetic and functional benefits, including light blocking, heat dissipation, and enhanced signal performance, suitable for electronics.

Flex PCBs fit into devices, saving space, while Rigid-Flex PCBs combine flexible and rigid parts, ideal for varied applications. PCBX offers custom designs, rapid prototyping, and high-quality manufacturing.