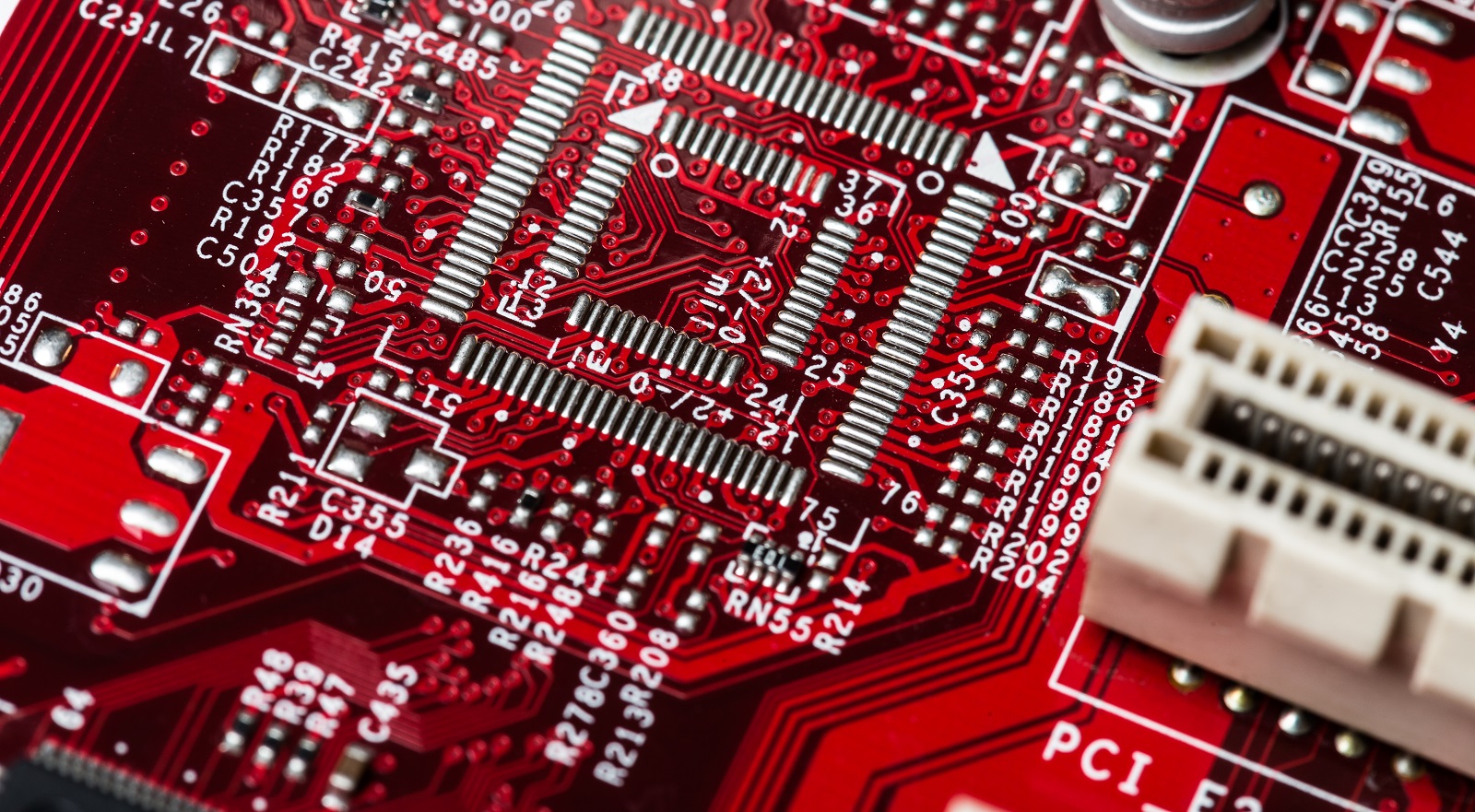

Red PCBs

Red PCBs offer aesthetic and functional benefits like enhanced visibility and noise reduction, making them a versatile choice despite green's dominance.

In the complicated manufacture of electronics, printed circuit boards are at the core of these modern devices, enabling their mode of operation. They are a backbone to electronic systems, providing a sort of physical platform on which other electronic parts are mounted and connected. One of the important and basic characteristics that a PCB possesses includes color, basically defined by a solder mask layer overriding the copper surface on the board. While ubiquitous green is the most common, the red PCBs have carved their niche with some functional and aesthetic advantages that please many an engineer and designer.

First of all, to understand better the implications of colors on PCBs, it has to be realized that the color is a result of the solder mask and not the circuit itself. The solder mask is the colored lacquer-usually impregnated with pigment-laid upon the PCB for insulating and shielding the board's copper traces. These traces are very critical to the functioning of the board, hence the protection from short circuits and moisture and dust in the environment will be done. The solder mask inhibits mechanical wear and protects the board by various risks related to everyday use and extreme weather conditions.

The color, including red, offers a view in contrast to copper wires for better visual inspections by the technician to identify problems on the assembly or maintenance of a product. Thus, it will also serve as a protective and communicative layer for effective detection and correction of errors with speed.

The Distinctive Appeal of Red PCBs

While red PCBs are caught up with their striking color, they have become the darling in applications involving differentiation. The color red usually applies to specific use cases for rapid identification, either in complex assemblies or where many boards are applied. This visual distinction enables technicians to identify the type or function of a particular board rapidly.

Advantages of Red PCBs

Improved Visibility and Aesthetic Contrast: One of the major advantages of red PCBs is their great contrast with copper traces and labels. This improved visibility promotes error-checking, enhancing trace examination during quality control processes. While green offers high visibility, red adds an element of aesthetic appeal that may be critical in consumer-facing products.

Ease of Repairs and Maintenance: Red PCBs are designed in such a way that maintenance is easy. The clear marking, highlighted with contrasting silkscreen, makes identification and troubleshooting really fast. Technicians can easily get to the site of the faulty component and repair it. The markings on the red background are clear, thus making them easy to read.

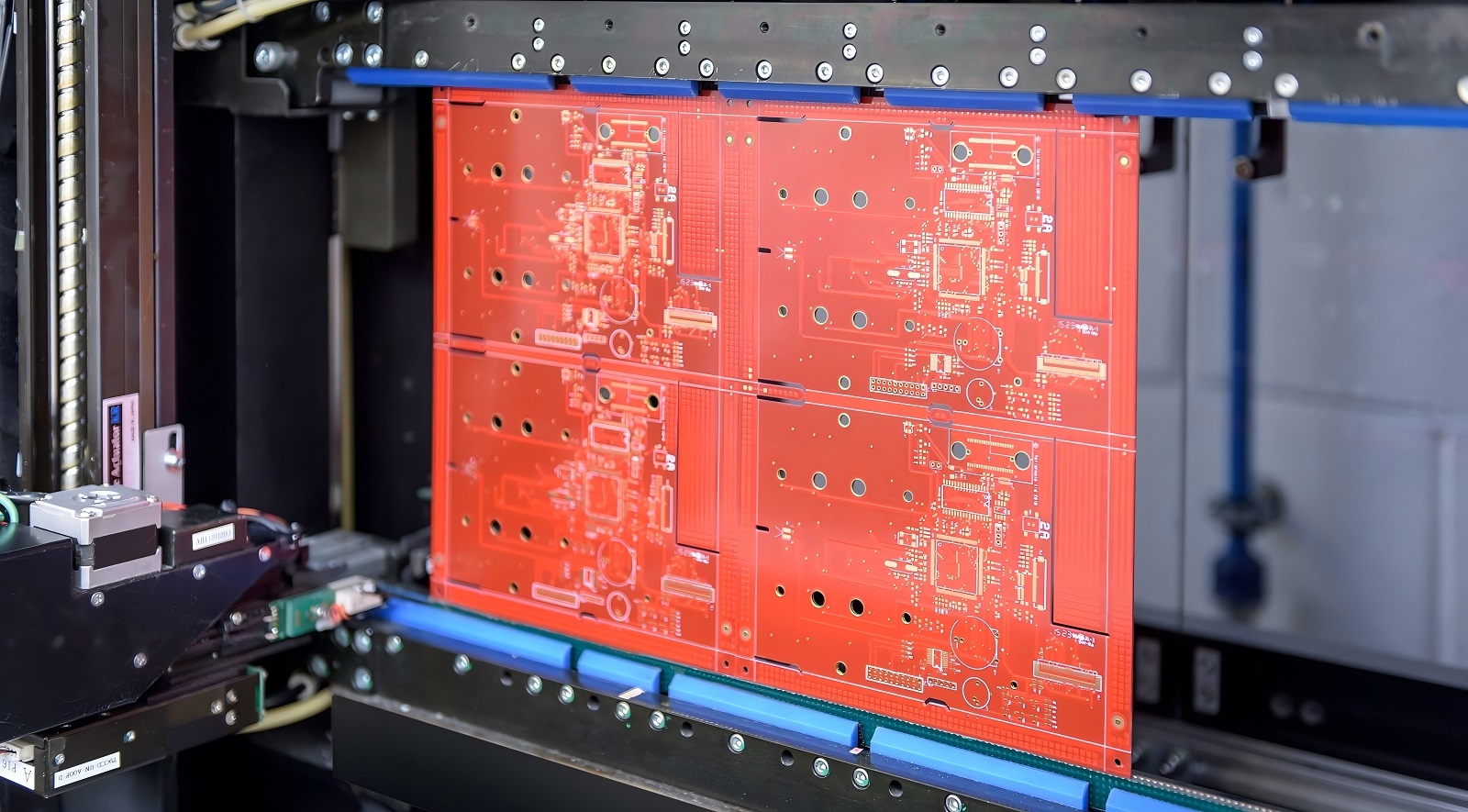

Time and Effort Efficiency in Production: The production of the red PCBs is efficient and time-saving, since technology has advanced in the printing of PCBs. Such boards can be produced much faster compared to the time taken by conventional methods. This aspect is helpful for industries that rely on rapid prototyping and production.

Reliability of Component Mounting: Components in red PCBs are firmly mounted with dependable solder flux to minimize the possibilities of dislocation. The result is dependability of electric connectivity, hence less chance for short circuiting; therefore, making a product that can last and be reliable.

Noise Reduction Capabilities: One of the rarely mentioned benefits is the noise reduction capabilities of a PCB in design. By placing components and traces carefully, the red PCBs are designed to minimize electromagnetic interference and radiofrequency disturbances for optimum performance, especially in precision equipment.

Cost-effectiveness: With the use of CAD systems, production templates of red PCBs can be stored and reused, making it very cost-effective to produce red PCBs, especially in large-scale manufacturing runs where the need to have batches of similar units produced with the least possible financial outlay is realized.

Comparisons with Other Colors of PCB

While red PCBs have many advantages, the industry uses a number of other colors that best suit particular applications. Green is the industry standard because it has gained widespread acceptance and performs well in connecting components. Other colors, however, like blue, white, yellow, and black, each have different properties that suit various engineering needs.

Green: Most known for their performance and dependability, green PCBs are usually applied when assemblies require high precision, especially in consumer electronics.

Blue: Most liked for its appeal in the looks of the technological components such as Arduino boards, blue provides decent visibility, although magnification may be necessary to see the details properly.

White: Difficult to maintain due to its lack of contrast, white is less used but offers a sleek look when appearance is paramount.

Black: Used by companies such as Apple in their high-end products, black boards have very minimal contrast and can highlight labels with bright silkscreens.

Yellow: This color provides almost the same contrast as green. Yellow is rarely used but is favored for its trace and empty space visibility.

Red PCBs effectively marry aesthetic appeal with considerable functional advantages, thus being a very attractive option for both manufacturers and designers. While green still dominates the industry due to its established reliability, the unique properties of red PCBs include enhanced visibility, noise reduction, and cost efficiency, creating a versatile option suitable for various applications.

Understanding the purpose of solder masks and the consequence of color will be important for any professional in electronics within the relentless race for the best quality and performance of their products. Because of their bright visibility and consistent protection, red PCBs are an exciting alternative to the ever-changing landscape of electronic manufacturing.

For a customized look at how red PCBs can upgrade your electronics projects, or to discuss the custom color that suits your needs, PCBX is always ready with expert guidance and solutions.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Green PCBs are favored for cost-efficiency, visual clarity, and durable performance, driven by historical and technical factors, with continuous innovations in materials.

Blue PCBs enhance electronics with aesthetic appeal, improved inspection, temperature resistance, and brand identity, offering unique advantages over traditional options.

Black FR4 PCBs offer aesthetic and functional benefits, including light blocking, heat dissipation, and enhanced signal performance, suitable for electronics.