Round PCB Board

Round PCBs offer design flexibility, space efficiency, and better heat management, ideal for wearables, LEDs, and telecom. Manufacturer choice is crucial.

In the fast-paced world of electronics, more and more PCBs are required with multiple shapes to meet various design and functionality needs. Of these, circular PCBs are one such fast-growing variant, which comes with several advantages for very particular applications. This paper elucidates the overview of circular PCBs, covering complexities in design, applications, and critical considerations while choosing a manufacturer.

A round PCB, or in other words, a circular PCB, is a printed circuit board in a round form factor. From the usual rectangular or square board, round PCBs bring a unique design flexibility; hence, they are better for devices needing non-conventional shapes. This design facilitates not just electrical connections but space utilization, too, within enclosures that are either circular or irregular.

Round PCB Design Considerations

Designing a round PCB presents a number of challenges that are unique, especially in circuit layout and component placement:

Complex Routing: The need for a circular shape requires very accurate planning of trace routing and component arrangement. Round PCBs require advanced design strategies and tools such as Eagle CAD. This software includes the "MITER" command, which enables designers to transform square layouts into circular ones efficiently.

Space Maximization: Space maximization is very important, considering signal integrity and effective component distribution. The use of sophisticated CAD tools, like Altium Designer, for customized power and ground planes, as well as the efficient strategic arrangement of components, may accomplish this.

Mechanical Integration: An exact fit between the round PCB and its enclosure is crucial. Prototyping and mechanical fit testing may be necessary in some cases, particularly for wearables or LED fixtures where accuracy is crucial.

Applications for Round PCBs

Round PCBs are used in a variety of contexts, particularly when their characteristics and form are best utilized:

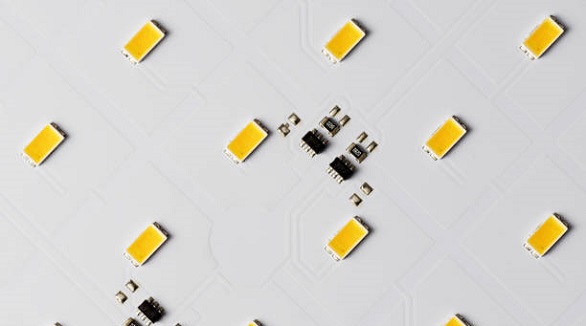

Round PCBs are used in LED lighting to provide even light distribution and effective heat dissipation, which are essential for optimal performance and long fixture life.

Wearable Devices: The wearable devices require designs that will not bother wearers during activity; therefore, round, compact-shaped PCBs perform excellently.

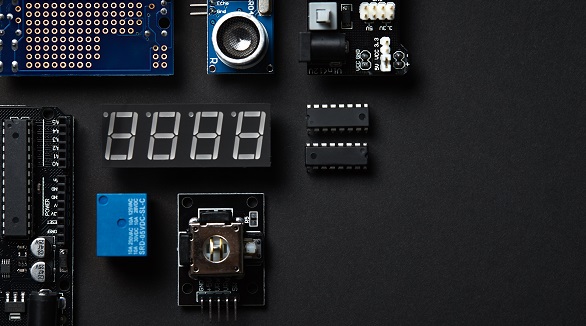

Consumer Electronics: Round PCBs are utilized in items like smartwatches by saving space to increase user interface design with aesthetic appeal.

Medical Equipment: Round PCBs are used in medical devices due to their precision and suitability for form factor, which is very important in designs such as hearing aids and monitoring equipment.

Telecommunications: Telecommunications equipment benefits from the efficiency and flexibility of round PCBs by facilitating advanced network system configurations in compact enclosures.

Types of Round PCBs

There are various types of round PCBs, each designed for a specific need.

Single-Sided Round PCB: These have one conductive layer and are the cost-effective solution for very simple, low-density designs.

Double-Sided Round PCBs: These PCBs include conductive layers on both sides and thus have additional design flexibility for higher complexities.

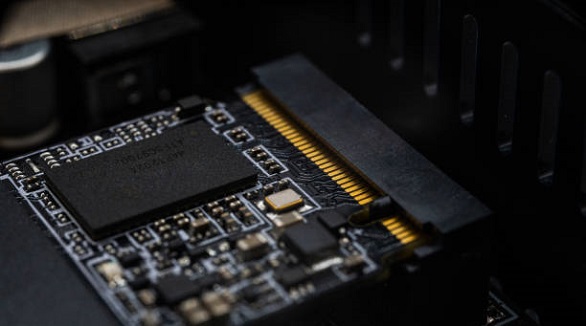

Multilayer Round PCBs: With a number of conductive layers, these are suitable for high-speed and complex devices requiring high circuit density and precision.

Advantages of Round PCBs

Round PCBs come with several merits that make them preferable in certain applications:

Space Efficiency: The round shape allows for the best use of space, particularly in devices with non-standard enclosures, reducing wasted space and allowing for efficient designs.

Aesthetic Value: Round PCBs add to the aesthetic value of consumer electronics, which is critical to their market appeal, especially when it comes to lifestyle and wearable technology.

Better Heat Management: Due to the radial symmetry in round PCBs, heat could be distributed more evenly, which becomes quite necessary for components with higher thermal output.

Better Signal Integrity: In communication and high-frequency applications, a well-designed circular PCB can provide better signal integrity with less electromagnetic interference.

Choosing the Best Manufacturer for Round PCBs

Because of its complexity, round PCBs require careful consideration when selecting a manufacturer:

Experience and Proficiency in Manufacturing: Choose those who have produced round PCBs for many years. Request details on previous projects completed and ask about their position within the industry to make certain the products are of good quality and reliable.

Assurance of Quality: The manufacturers shall undertake thorough testing, including E-tests and thermal stress tests, to certify the functionality and quality of PCBs.

On-Time Delivery: Assess how the manufacturing firm will be punctual with your product delivery since development cycles move very fast.

Customer Support: Choose manufacturers that offer robust customer service, including technical assistance and customization capabilities to meet specific project requirements.

Circuit rounds are essential in a variety of innovative applications because of the flexibility they introduce to design, the utilization of space, and an enhanced aesthetic appeal. In reality, although the designing and manufacturing process is not quite as smooth, these problems can be overcome with modern design tools and by involving manufacturers with relevant experience. Round PCBs will become even more essential in meeting the demands of contemporary technology due to the growing demand for complex circuits. Designers and manufacturers may use round PCBs to produce unique products in a variety of sectors by being aware of its uses, benefits, and manufacturing needs.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

LED PCBs power modern lighting with efficiency and adaptability, ideal for diverse applications. Their design emphasizes thermal management, cost-effectiveness, and versatility, driving sustainable illumination solutions.

Black FR4 PCBs offer aesthetic and functional benefits, including light blocking, heat dissipation, and enhanced signal performance, suitable for electronics.

IoT and RFID integration revolutionizes device communication, improving data, asset, and operational management. PCBX supports these innovations amid challenges.