Start-Stop Circuits

Start-stop circuits efficiently control devices, enhancing safety and performance in industrial and consumer applications through simple push-button mechanisms.

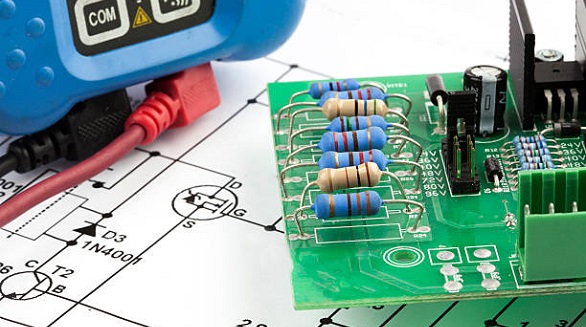

Start-stop circuits are a basic component in the electronics world, especially in industrial automation and consumer electronics. Start-stop circuits offer an efficient and dependable way to regulate the functioning of electrical devices like motors and equipment, improving safety and operational performance. This article explores the basics, components, configurations, and applications of start-stop circuits and provides an extensive understanding of their function in contemporary automation and control systems.

A start-stop circuit is utilized to regulate the power state of an electronic device so that it can be turned on or off by a straightforward mechanism, which is usually a push button. Such circuits form the basis of control systems requiring strict control over machinery, ranging from industrial conveyor belts to home appliances.

Key Components of Start-Stop Circuits

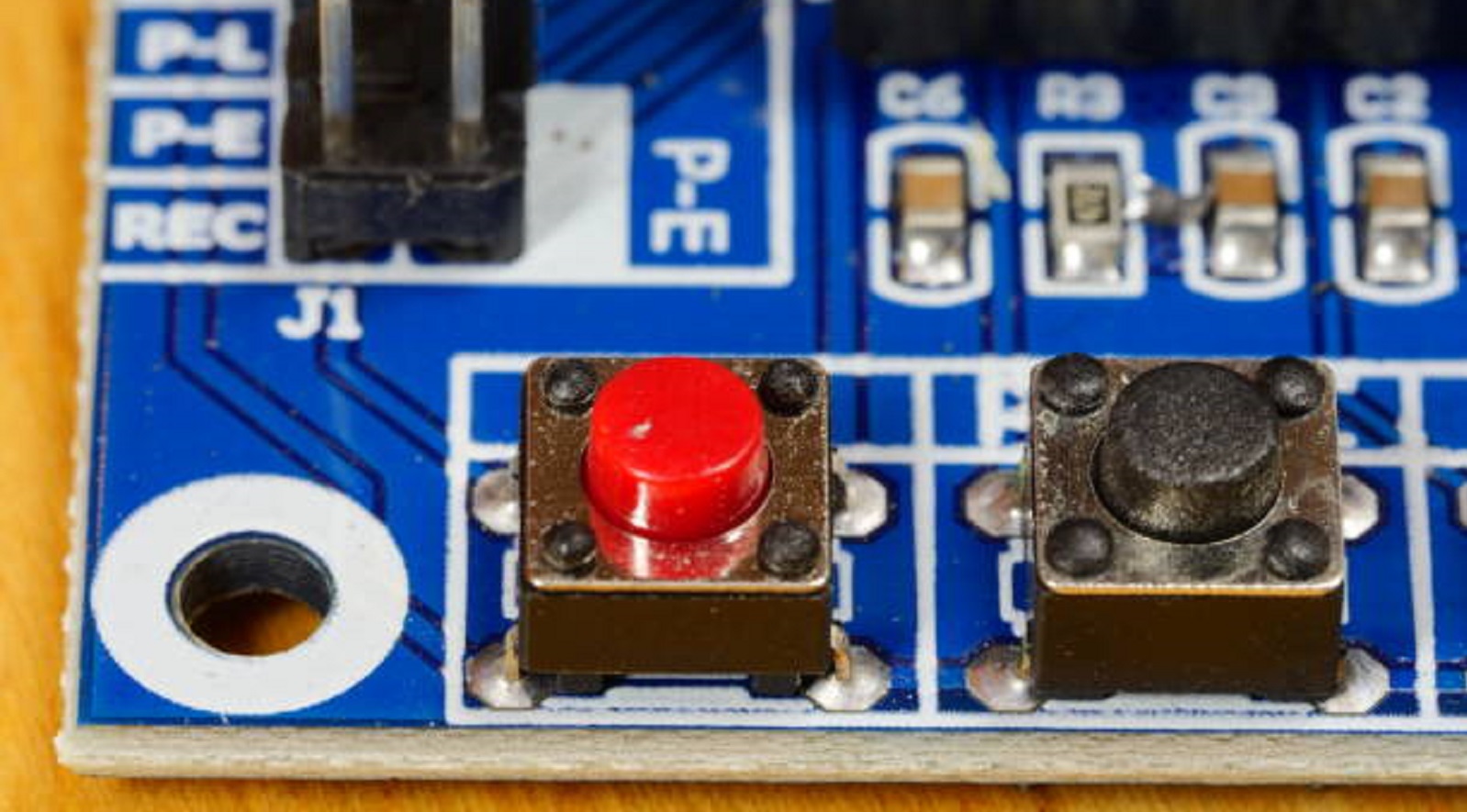

Push Buttons:

Start Button: This is a momentary contact switch which, when pressed, makes power flow into the machine or device.

Stop Button: This is also a momentary contact switch and interrupts power flow when pressed to make the machine or device stop.

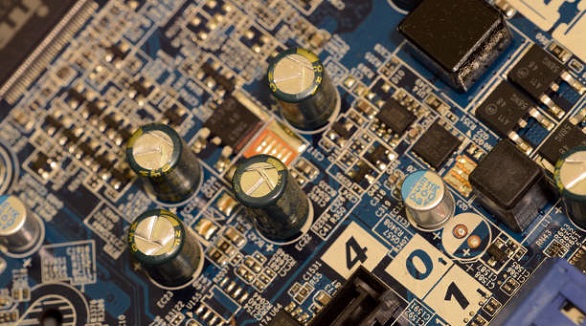

Relays and Contactors:

Relays: These are electrically operated switches to turn on or off low current circuits. They come in normally open (NO) or normally closed (NC) form, thus making the circuit able to be designed with flexibility.

Contactors: Similar to relays but with a higher current handling capacity, contactors are applied to directly control large electric motors. They remain open until activated by a relay coil.

Motors:

Motors consume electrical energy and transform it into mechanical energy. Motors are the focal point of start-stop circuits since they are the device that is most frequently being controlled and are extensively employed in conveyor systems and industrial applications.

Overload Protection:

Overload relays protect the circuit. They sense excessive current flow and disconnect the circuit to prevent overheating and damage.

Electrical Supply:

Start-stop circuits are regulated by a special control voltage, which is typically 24V DC. Low control voltage allows safe handling with the power to control the devices that can require different powers to function.

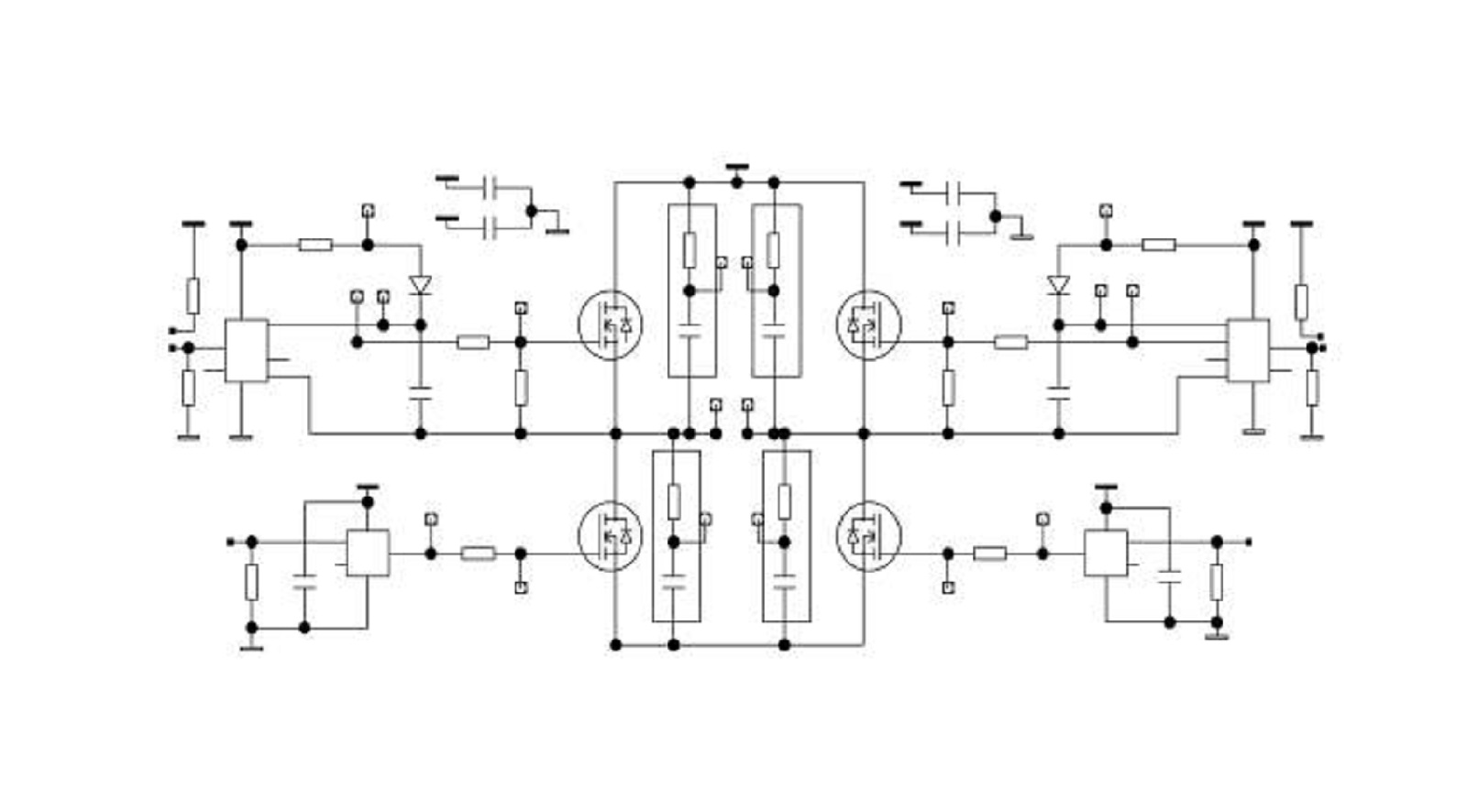

How Start-Stop Circuits Work

Functionality of a start-stop circuit involves a control circuit that determines the state of the relay or contactor and thereby the main power circuit of the device.

Initial State: The circuit remains de-energized with the relay or contactor being de-energized with no power transmitted to the associated device. The stop button is open normally so it does not pass current, whereas the start button is closed.

Start Activation: Pressing the start button makes the circuit short for a split second, which powers the relay coil. This closes the contactor, and the main power goes to the device. The contactor remains closed due to auxiliary contacts, which keep the circuit closed even when the start button is released.

Stop Operation: When the stop button is pressed, it breaks the circuit, taking away the energy from the relay or contactor coil and thereby opening the contactor and de-energizing power to the device.

Control Methods for Start-Stop Circuit Wiring

Two-Wire Control

Two-wire control uses a single pilot device for circuit control, offering convenience ideal for use in applications where there are few control points.

Operation: Here, turning power back on automatically completes the circuit, so instant restart when power is restored externally is possible. This is best for circuits that rely on external conditions like pressure fluctuations, e.g., pumps.

Three-Wire Control

Three-wire control circuits are safer and more suitable for more complicated systems where manual action is required for restarting the circuit.

Operation: Employing momentary start and stop buttons with sealing contact. When the start button is let go, the control circuit energizes the relay coil, and the sealing contact maintains the circuit after letting go of the button, until the stop button is let go.

Start-Stop Jog Circuit and Advanced Control

Jogging is brief, periodic running of a motor. A jog circuit allows temporary motor running without continuous use, as required during alignment movements or precise positioning.

Implementation: A jog circuit skips the sealing contact, allowing quick engagement and disengagement of the motor for control with rapid on-off operation without continuous main circuit operation.

Applications of Start-Stop Circuits

Start-stop circuits are used in most industries due to their efficiency and reliability. Some of their notable applications include:

Industrial Automation: Essential in factories for controlling conveyor belts, automatic tools, and process equipment.

Home Appliances: Used in appliances like washing machines and dryers to control operation cycles precisely.

Vehicle Systems: Modern vehicles implement start-stop systems to conserve fuel and reduce emissions by turning the engine off on idling and back on again when needed.

Protection and Emergency Systems: Applied for use in emergency stop circuits for quickly and efficiently stopping equipment without accidents and failure of equipment.

Start-stop circuits play important roles in operating the safety and efficiency of today's machinery and electronic systems. Their simplicity of design and functionality strength make them an essential part of ensuring that electric motors and devices work as expected with minimal risk and maximum reliability. As automation is on the increase, knowledge and utilization of start-stop circuits are critical for engineers and technicians to optimize control systems. With start-stop technology, combining manual and automatic processes becomes possible without any hitch, making safety and performance of industrial and consumer applications even more improved.

Whether you are creating these circuits in a factory environment or even simply using them for home automation, learning start-stop circuits will significantly increase your electronic system's functional capability, paving the way for intelligent, secure, and more efficient technological developments.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

The 94V-0 circuit board ensures safety in electronics by meeting fire resistance standards, essential for compliance, reliability, and reduced liability in devices.

Current limit control circuits safeguard electronics by regulating excess current, ensuring device safety and reliability across various applications and industries.

PCB short circuits arise from unintended connections, leading to safety risks. Prevention involves isolation, inspections, and thermal protection, ensuring device reliability and safety.