The Applications of Printed Circuit Boards

PCBs are vital components in most electronic devices, including consumer electronics, medical devices, and automotive systems. PCBX offers diverse, high-quality PCBs, driving modern technology with innovation and reliability.

Printed circuit boards (PCBs) are truly the unsung heroes in the background that have made today's technological world a reality. They comprise the very building blocks or vital components of almost every electronic device one uses in life, from smartphones and computers to medical appliances and auto systems. Indeed, their design process and history have contributed to impressive leaps and bounds in diversified industry sectors; therefore, their place in modern times cannot be overlooked. The article gives insights into the multifaceted uses of PCBs, describing their roles in consumer electronics, industrial equipment, medical devices, automotive systems, and more.

What are PCBs?

PCBs are made from a nonconductive substrate with a layer of copper circuitry above; these circuits interlink different components of the electronics. Such boards can be obtained in several kinds to suit particular requirements:

- Single-Sided PCBs: These have one layer of conducting material and hence are simple and inexpensive. They are largely used with low-complexity devices like calculators and printers.

- Double-Sided PCBs: Having conductive layers on both sides, these make provisions for more complex routing and are applied in LED lighting and vending machines.

- Multi-layer PCBs: These have more than two conductive layers and mainly find application in high-density applications like computers and GPS technology.

- Rigid PCB: These boards are solid and inflexible; these boards find applications where the shape stability of the equipment is very important—for instance, mobile phones and medical equipment.

- Flexible PCBs: Constructed with flexible plastic substrates, they are used in applications where bending and weight saving is necessary: automotive electronics, wearable devices, etc.

- Rigid-Flex PCBs: This variety combines elements of both rigid and flexible boards and is used in products requiring thin, lightweight, and flexible deployments, such as pacemakers and digital cameras.

Consumer Electronics

PCBs come to the fore in the consumer electronics industry, powering a plethora of devices that we use in our daily lives:

Communications: Smartphones, smartwatches, tablets, and radios—all make use of detailed circuitry provided by means of PCBs.

Computers: Home desktops, laptops, workstations, peripherals, monitors, and printers are all based on PCBs.

Entertainment Systems: TVs, stereo systems, DVD players, and gaming consoles all rely on the PCB.

Home Appliances: Many of the everyday appliances around the home—things like microwaves, refrigerators, coffee makers, and alarm clocks—all use a PCB.

Mass production of high-quality PCBs has been necessitated by the demand for reliable, high-performance consumer electronics. Manufacturers have to adhere to very strict quality control standards in ensuring the safety and efficiency of devices.

Industrial Applications

PCBs find an extensive application in industries in automation and power management:

Industrial Equipment: It finds a place in machines applied in the assembly lines, presses, and ramps that incorporate robust PCBs.

Power Equipment: Devices that include power supplies, inverters, and distribution systems use specially designed PCBs.

Measuring Equipment: Devices used to control temperature, pressure, and other parameters during manufacturing processes use PCBs.

Industrial environments can be very hostile. PCBs used in these environments have to be able to withstand such extremes as chemicals or high temperatures. Flex-rigid PCBs are the best positioned for such demanding applications due to their durability and flexibility features.

Medical Devices

The greatest effect of developing PCB technology would be realized in the medical field. Among the applications are the following:

Diagnostic Equipment: These devices are at the heart of devices like X-ray machines, CT scanners, and ultrasound equipment.

Monitoring Devices: Heart rate monitors, blood glucose meters, and blood pressure monitors all rely on the accuracy of PCBs.

Medical Instruments: It is through the aid of a PCB that data is collected for analysis in devices such as research instruments like electronic microscopes and control systems.

The fact that medical devices are life-critical places a premium on the quality and reliability expected of PCBs used in this sector. They are mostly compact in design and have to adhere to strict health regulations.

Automotive Applications

The use of PCBs is becoming more extensive in the automotive sector, especially with the growing trend towards electric and automated vehicles. Typical applications include:

Navigation Systems: Satellite navigation systems housed in-car use multilayer PCBs for accurate performance.

Media Devices: Multimedia connectivity-based high-end dashboards are all driven on complex PCBs.

Control Systems: Systems controlling the performance of an engine, fuel efficiency, and power supply depend on robust PCBs.

Proximity Monitors: Quality PCBs are in use with sensors facilitating parking and blind-spot monitoring for proper functioning and reliability.

These PCBs have to withstand high vibrations and extreme changes in temperature. So, they normally have flexible ones as those exhibit resiliency and flexibility according to vehicle contours.

Security and Safety Devices

Quality PCBs in security systems offer the operation of security cameras as continuous in nature.

Access Control Systems: Electronic locks and entry systems work on PCBs for secure and effective operation.

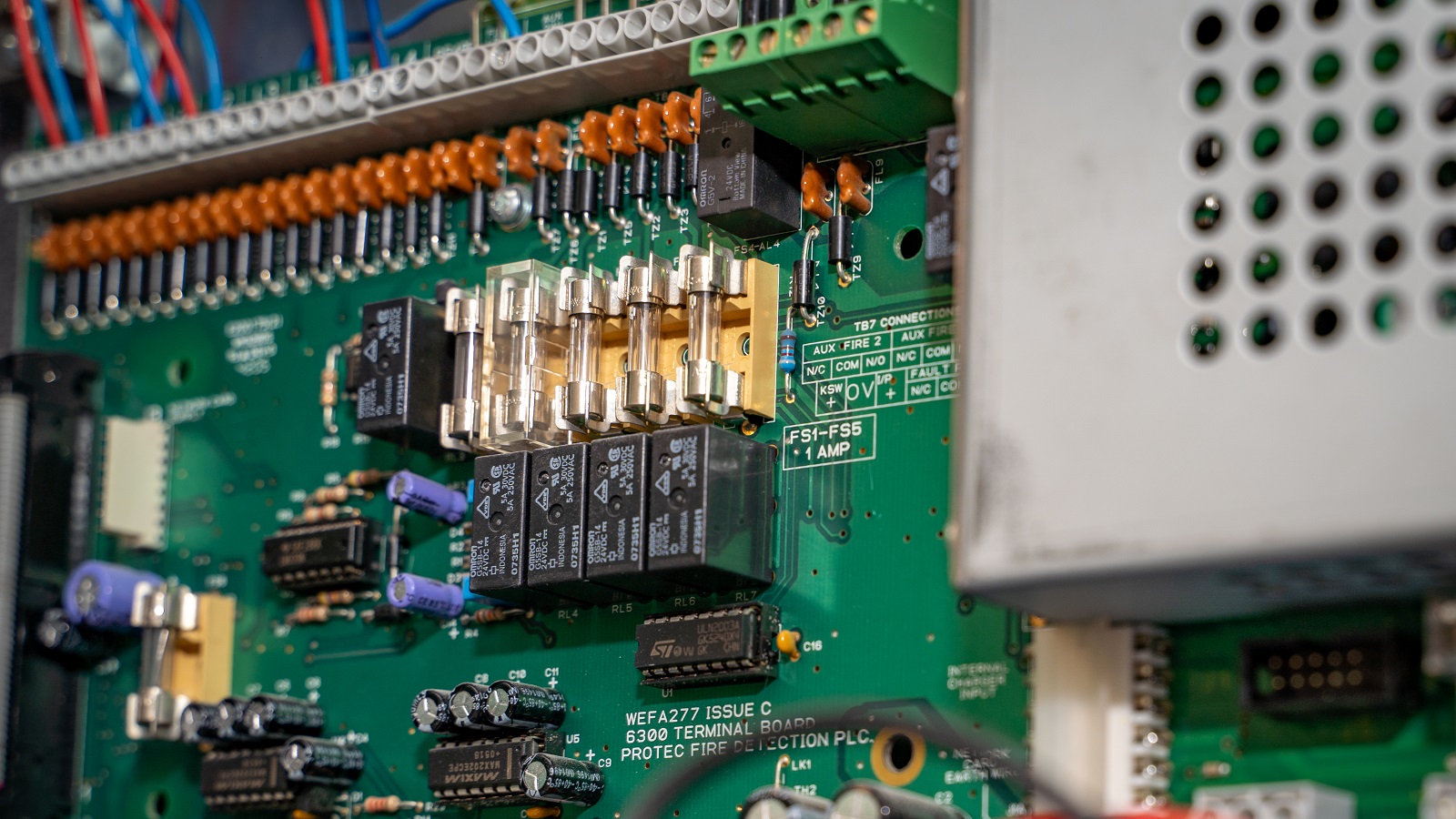

Fire and Safety Systems: Smoke detectors, alarm systems use PCBs to keep on functioning.

For such critical applications, PCBs are required to be extremely reliable and hardened against various environmental conditions.

Choose PCBX for Your PCB Needs

The versatility of PCBs allows them to cater to the demands of specific applications, ranging from simple single-sided boards to complex multilayer configurations. With improving technology, uses of PCBs are going to increase and development is going to happen in many industries. Very clearly, the future will be partially fashioned by a seamless continued evolution of the technology of PCBs.

From smartphones and computers, medical appliances to automotive systems, PCBs are an important part of nearly each electronic gadget in existence. At PCBX, we provide a variety of PCBs for different industries and their needs. Quality and technological leadership have made products at PCBX the backbone of modern technology.

With PCBX, you can avail the fullest extent of industry knowledge, rigid control of quality, and PCBs in so many variants. Innovation, ever-increasing technological requirements, application-tailored solutions, and manufacturing excellence are the cornerstones of the business.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

PCBs are essential for organizing information and power flow in electronic devices, benefiting from flexibility, durability, safety, efficiency, and heat management.

Most electronic circuits are mounted on PCBs, or Printed Circuit Boards, which provide mechanical support and electrical interconnection of electronic components. There are, however, special applications that involve the use of single and double-sided PCBs, multi-layer PCBs, or even rigid and flexible PCBs with aluminum backing, targeting medical, industrial, auto, and aerospace industries. They may use materials such as fiberglass, epoxy, aluminum, and others.

The article explains the current situation of Printed Circuit Boards and future development based on efficient production helped by advanced software and manufacturing processes. Future technological developments are in store for 3D Printed Electronics, flexible PCBs, eco-friendly biodegradable PCBs, and board cameras. It elaborates on other powerful automation tools that are going to make the entire PCB design process efficient in the near future. All of them will further improve and develop with the technological advances in PCBs, keeping up with the ever-increasing industry and consumer demands.