The Best Solders for Circuit Boards

Explore solder selection for circuit boards: understand types, best brands, and safety tips to ensure strong, reliable connections and optimal performance.

Soldering involves the making of safe and secured connections among parts. Proper solder choice, both for professional and hobbyist makers, is essential in equipment reliability, life span, and performance. In this regard, we at PCBX recognize such importance by presenting to you the ultimate guide on the best solders that exist for circuit boards, further supported by an overview of the best types for a variety of electronic projects.

At the core, solder is a metal alloy serving as an active agent in joining electrical elements to printed circuit boards, providing conductivity. Unlike many people's belief, solder is not a wire but a tube made of metal that is designed to melt at a heating temperature so it can join elements of different natures. This melting and solidification provide a physical and electrical connection between component leads and the copper traces on the PCB to offer both electrical and mechanical stability.

Types of Solders

Lead-Based Solder (Tin-Lead Solder, SnPb)

Lead-based solder has stood the test of time as the industry standard due to its low melting point, ease of application, and strong mechanical properties. It generally comes in a 60/40 tin-lead ratio and works very well in making smooth, reliable connections with minimal effort. Due to environmental and health concerns with lead, the use of lead-based solder has been declining and is being replaced by lead-free solders.

Lead-Free Solder

Due to the stringency of environmental legislations around the world, like the one imposed by the RoHS directive, the trend that the electronic industry adopts is the usage of lead-free solders. Examples of such widely used lead-free alloys are SnAgCu, SnCu, and SnBi. Even though most of them usually have a higher melting temperature than their lead-containing analogs, the main reasons for their adoption are the smaller environmental impacts and their compliance with the set international standard.

Forms of Solder

Solder Wire

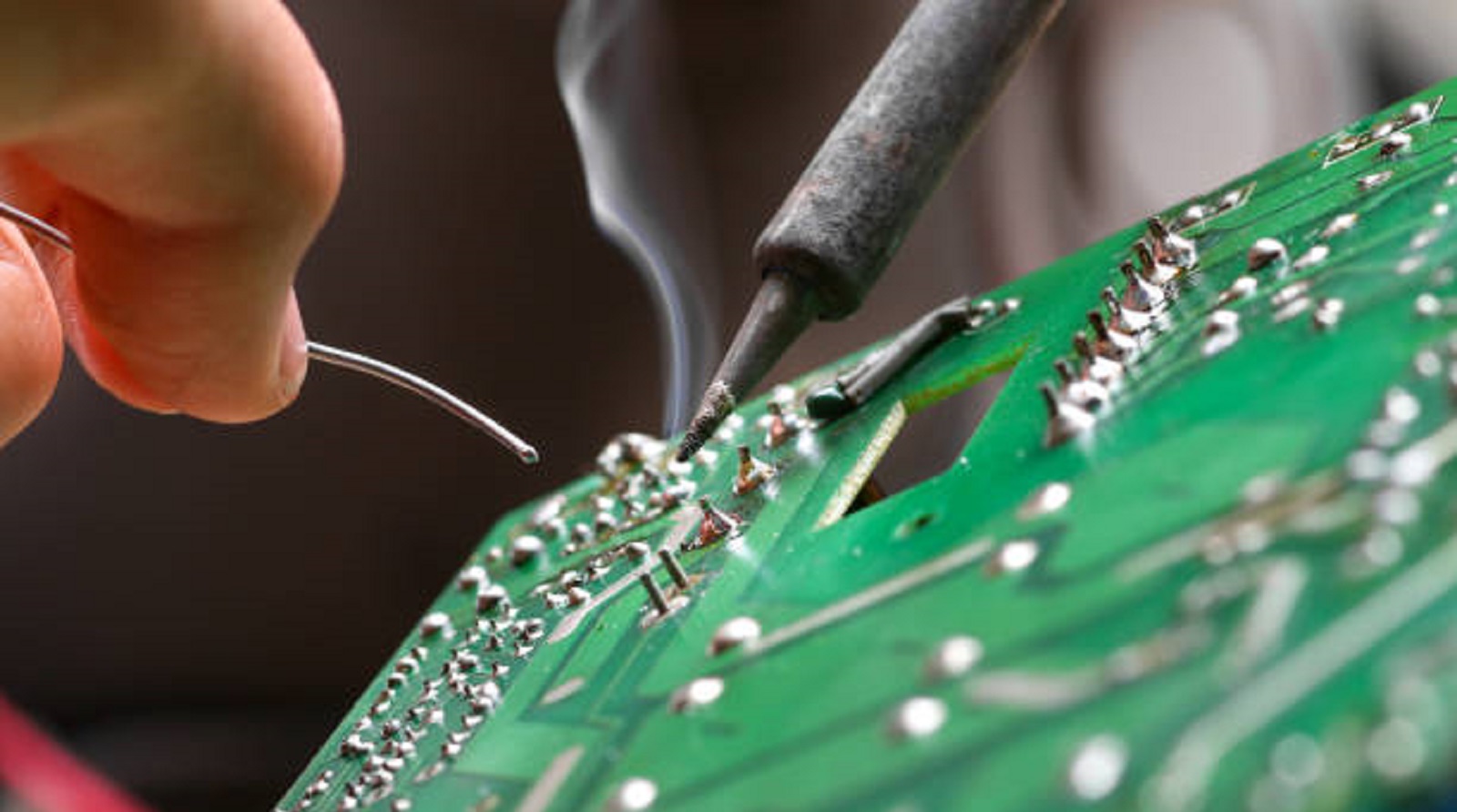

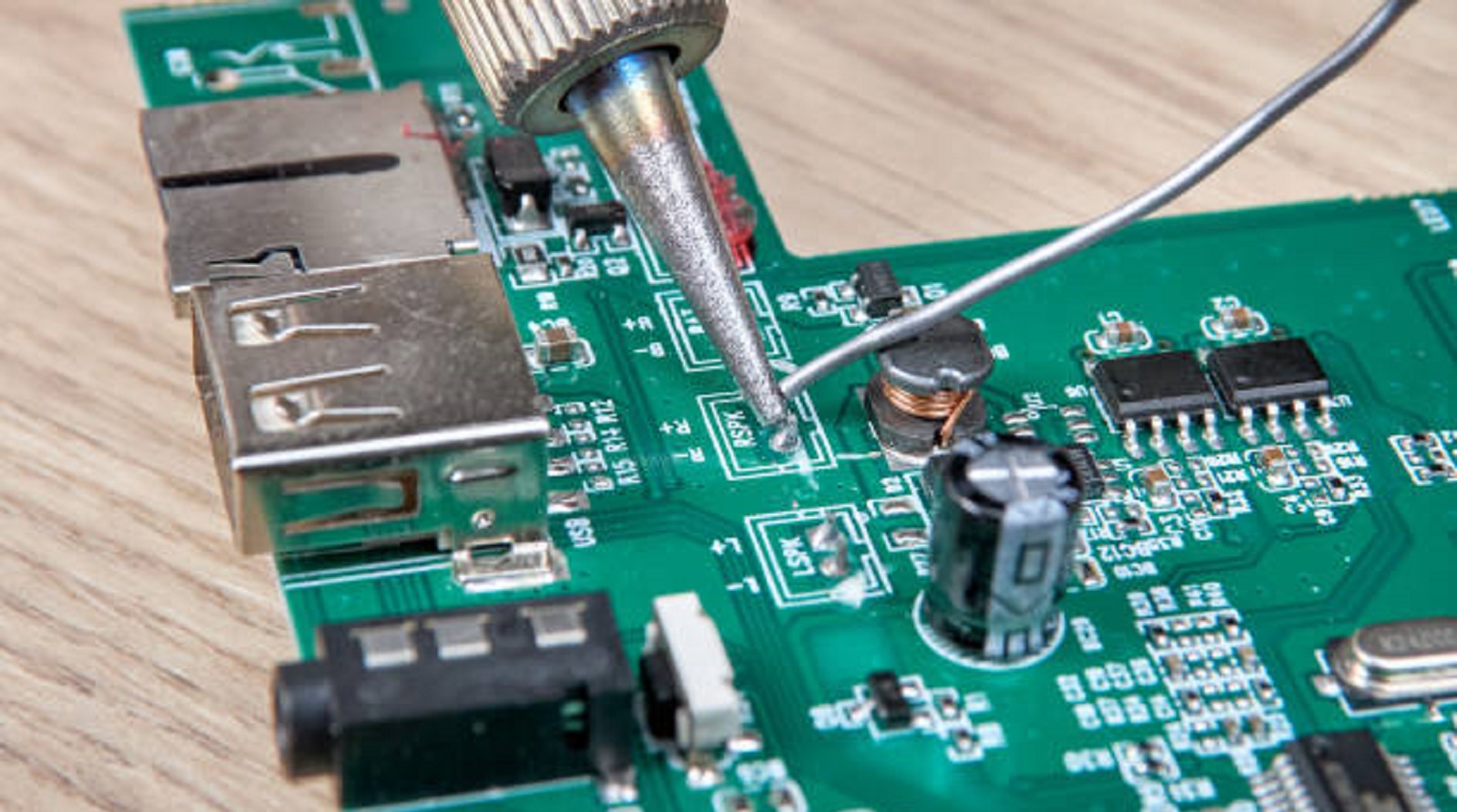

Solder wire is one of the most versatile and convenient soldering options, especially in manual soldering. Used together with a soldering iron, solder wire is ideal for through-hole components and touch-up jobs on surface-mount components. It allows for precision and control, hence being a favorite for both beginners and seasoned professionals.

Solder Paste

Mainly utilized in surface mount technology, solder paste is a mixture of fine solder particles combined with flux. This paste is applied on the PCBs using stencils or dispensers for placing components in accurate positions. After attachment, the board is heated under controlled conditions in a reflow oven, where the solder gets melted and forms strong joints.

Solder Bars

These solder bars are designed for use in wave soldering machines. Solder bars are melted in a solder pot to create a "wave" of molten solder. The wave is forced to flow over the underside of the PCB, thus efficiently soldering through-hole components into place.

Best Brands for Soldering Circuit Boards

Kester 44 Rosin Core Solder

Kester 44 Rosin Core Solder is considered a staple in the world of soldering. With its 63/37 composition, it offers a low melting point and strong, solid bond. Consistent and reliable, this one will not disappoint the hobbyist or the pro.

Pros:

Low melting point

Strong bond

Good for many applications

Cons:

Slightly more expensive

Alpha Fry AT-31604

The Alpha Fry AT-31604 is an all-purpose solder with a 60/40 tin-lead alloy that should serve general electronic work. The rosin core eliminates the need for additional flux, ensuring clean, quality connections.

Pros:

No additional flux is required

Effective on a variety of surfaces

Inexpensive

Cons:

Not suitable for lead-free projects

MG Chemicals 63/37 No Clean Solder

Known for its no-clean formulation, MG Chemicals 63/37 No Clean Solder eliminates post-soldering cleanup. It delivers strong bonds across various applications, providing both convenience and performance.

Advantages:

No residue cleanup

Strong bond

Versatile usage

Disadvantage:

Slightly higher price

WYCTIN 60/40 Solder Wire

WYCTIN 60/40 Solder Wire is a perfect blend of affordability and performance. Its low melting point provides a smooth soldering experience, ideal for DIY enthusiasts and small-scale projects.

Advantages:

Low melting point

Budget-friendly

Easy to use for hobbyists

Disadvantage:

Not as strong as premium options

SRA Soldering Products Rosin Core Solder

SRA Soldering Products provides a lead-free rosin core solder for those who would want to go green and stay away from lead. It is a good bond that works well with sensitive parts.

Pros:

Lead-free

Green

Good for sensitive electronics

Cons:

Higher melting point

Cardas Soldering Wire

Cardas Soldering Wire provides an audiophile's dream in wire as it is very pure for the best possible signal transfer in audio equipment, high end applications.

Pros:

High purity

Perfect for audio

Very high performance

Cons:

Too expensive

Harris Stay-Brite Silver Solder

Harris Stay-Brite has the benefits of silver solder sans the usual pitfalls. The lower melting point, along with toughness, makes it suitable for use in high temperature applications.

Pros:

Low melting point

Good strength

Suitable for high temp

Cons:

Costly

Worthington 60/40 Solder Wire

Worthington strikes a good balance between price and quality. With a rosin core, applying it is rather easy, and hence this one is trustworthy in most kind of soldering jobs.

Pros:

Rosin core

Cheaper

Versatile

Cons:

Not for lead-free apps

How to Choose Solder

Composition: The choice between lead-based and lead-free solder shall be based on environmental regulations and the specifications of the job.

Melting Point: The selection should have a melting point suitable for the components to avoid their damage and ensure strong joints.

Flux Type and Diameter: The type of flux-rosin, water-soluble, or non-clean-and solder diameter are selected with the application based on required precision.

Safety and Tips while Soldering

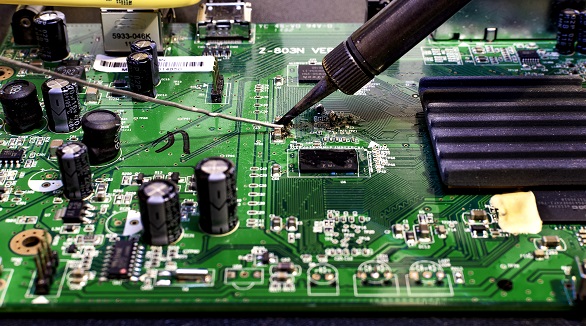

Soldering is very rewarding but requires a lot of vigilance and following all the safety protocols. Always work in a well-ventilated area to avoid inhaling fumes, and equip yourself with safety gear such as goggles and gloves. Keep your workspace tidy to avoid mishaps; ensure all soldering tools are safely placed when not in use. Inspect each solder joint for quality, featuring a smooth, shiny finish that is indicative of a good connection.

Soldering is way more than just a technical skill; it is a gateway to innovation in electronics. With the use of the best solder available for your project, you can create connections that make sure your devices function well. At PCBX, we are committed to giving you all the confidence you need to understand how things go when it comes to soldering and teaching you how to make good choices. Come aboard the electric journey and build the future, wire by reliable wire.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Solder masks protect PCBs, while paste masks aid precise component placement during assembly, both crucial for PCB reliability and efficiency in electronics.

SMD soldering mounts small components on the PCB surface for compact, automated designs but has high setup costs and repair challenges. DIP soldering uses through-hole components for robust, easily repairable, lower-volume applications.

The article provides a step-by-step guide to soldering a PCB, covering workspace setup, essential tools, and safety measures. It explains heating the soldering iron, applying flux, tinning the iron tip, placing components, heating joints, applying solder, cooling, inspecting, and cleaning. Emphasis is on practice and safety for successful soldering.